Finishing and ironing machine for sock and glove

A technology for ironing machines and gloves, which is applied to finishing appliances, laundry room devices, washing devices, etc., and can solve problems such as inability to set up, incapable of assembly line production, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

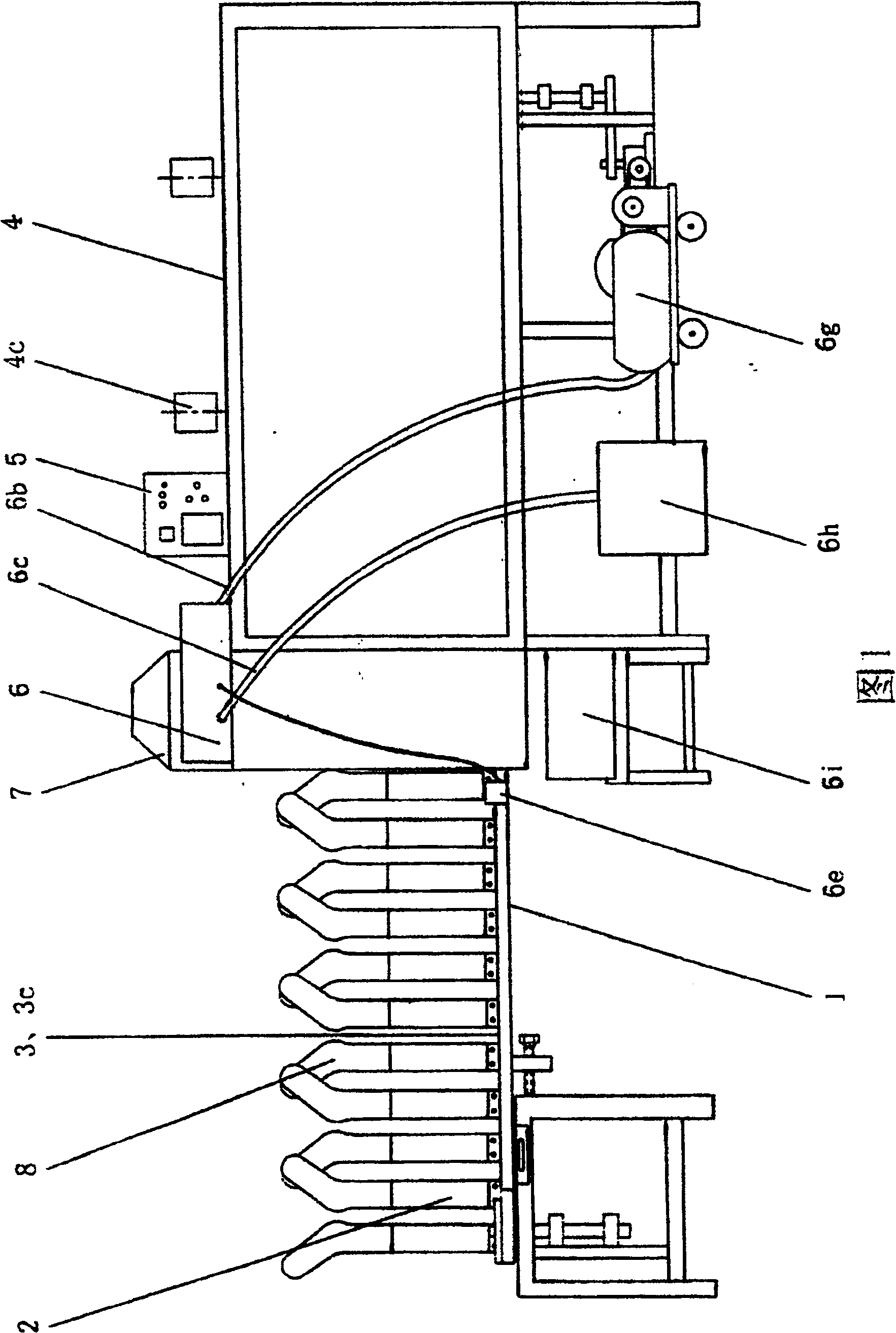

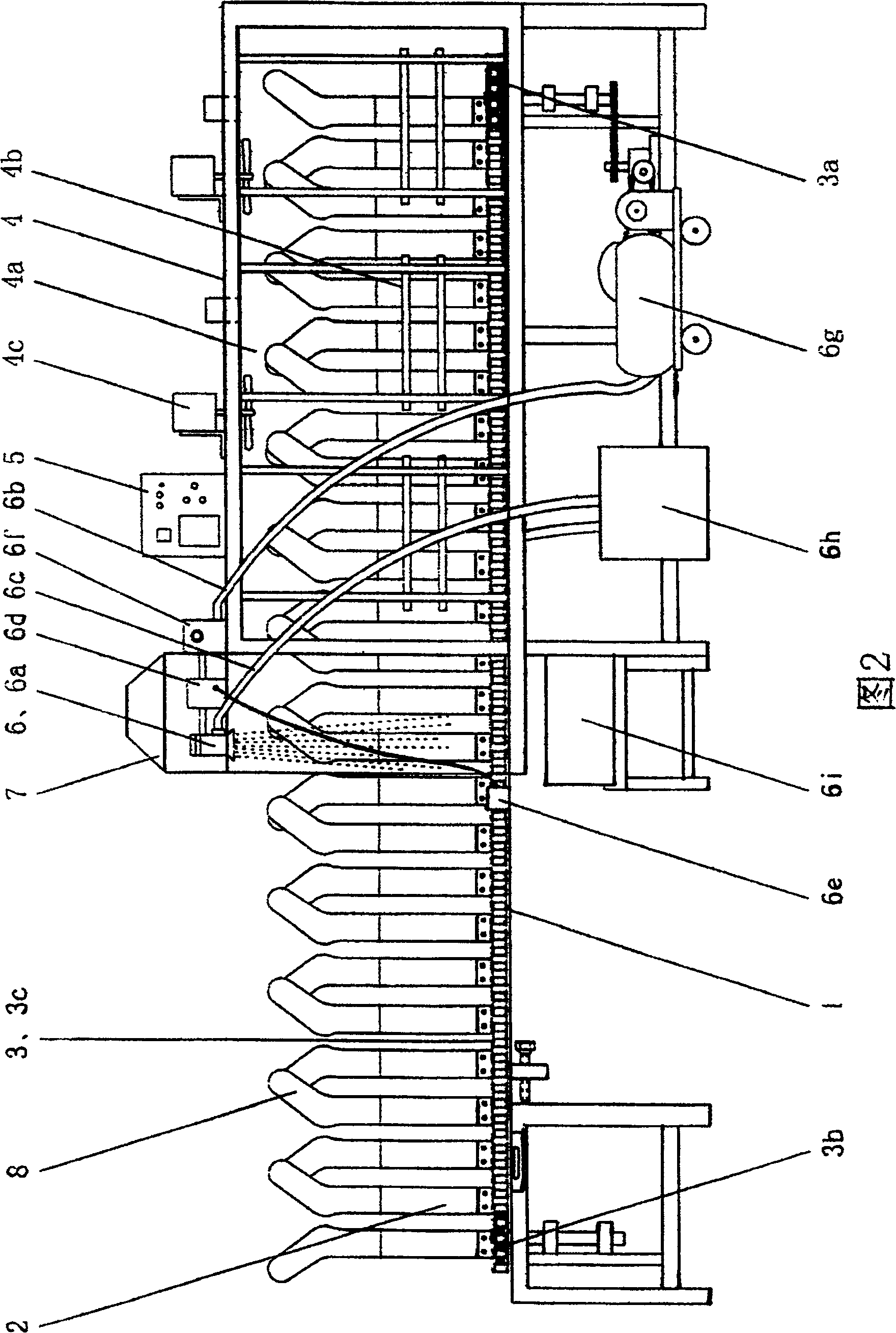

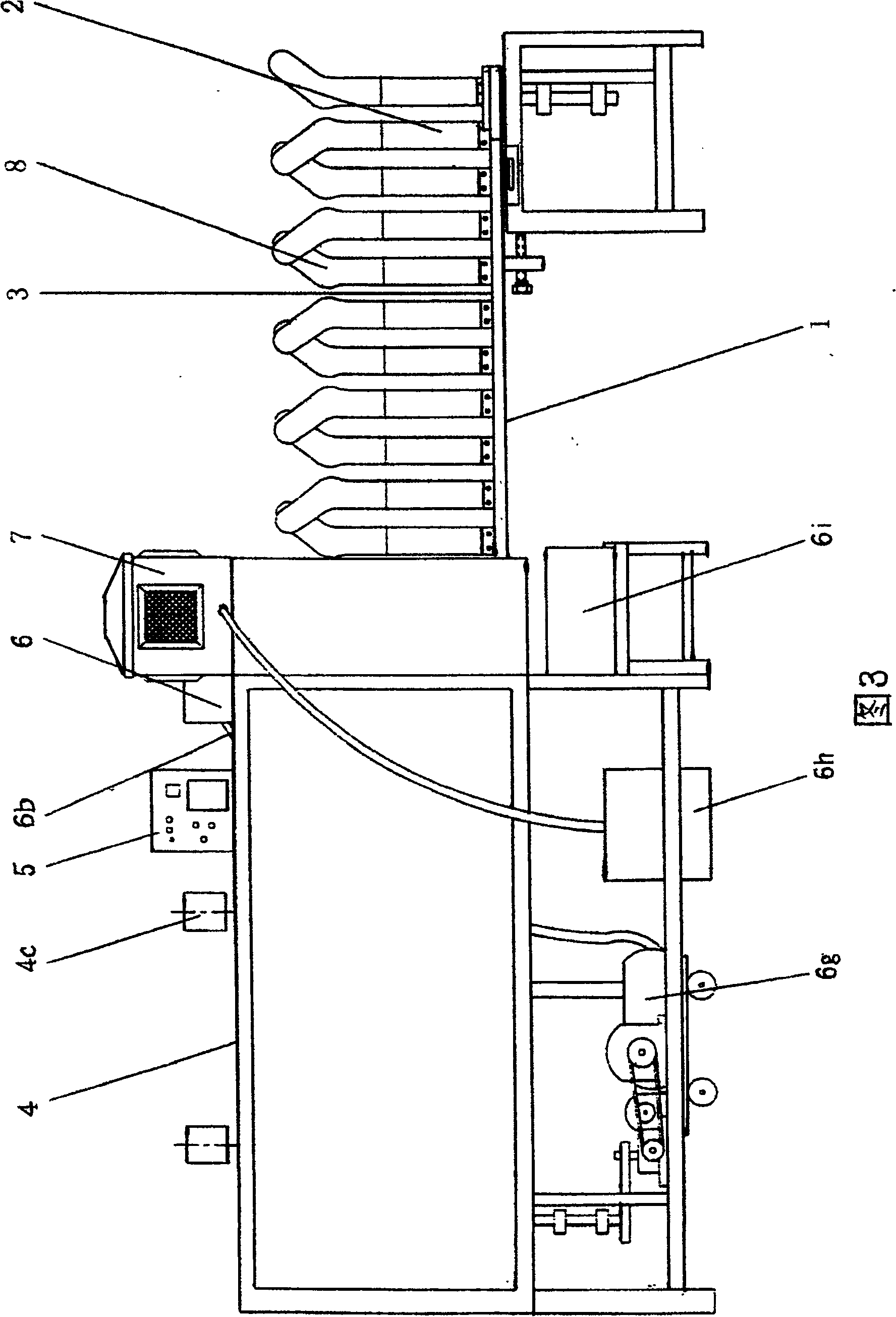

[0028] Depend on Figure 1-6 Shown is the first embodiment of the present invention, i.e. a sock ironing machine. This embodiment it comprises frame 1, socks template 2, template transmission mechanism 3, drying device 4, electrical control box 5, spraying water mist device 6, blowing cooling device 7. Spray water mist device 6 is made up of nozzle 6a, air pipe 6b, water pipe 6c, electronic valve 6d, control switch 6e, pressure regulating valve 6f, air compressor 6g, water tank 6h, and water storage tank 6i. The nozzle 6a is installed at the beginning of the drying device 4, the template transmission mechanism 3 transmits the top of the sock template 2, and the fine hole of the spray water mist of the nozzle 6a faces the sock template 2 that is transmitted below, and the air inlet of the nozzle 6a is connected to the conveying hole. One end of the air pipe 6b is connected, the other end of the air pipe 6b is connected to the electronic valve 6d on the air circuit, the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com