Multi-functional filter

A filter and function block technology, applied in the field of multi-function filters, can solve the problems that it can only be used for or condensate filters, and cannot be converted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

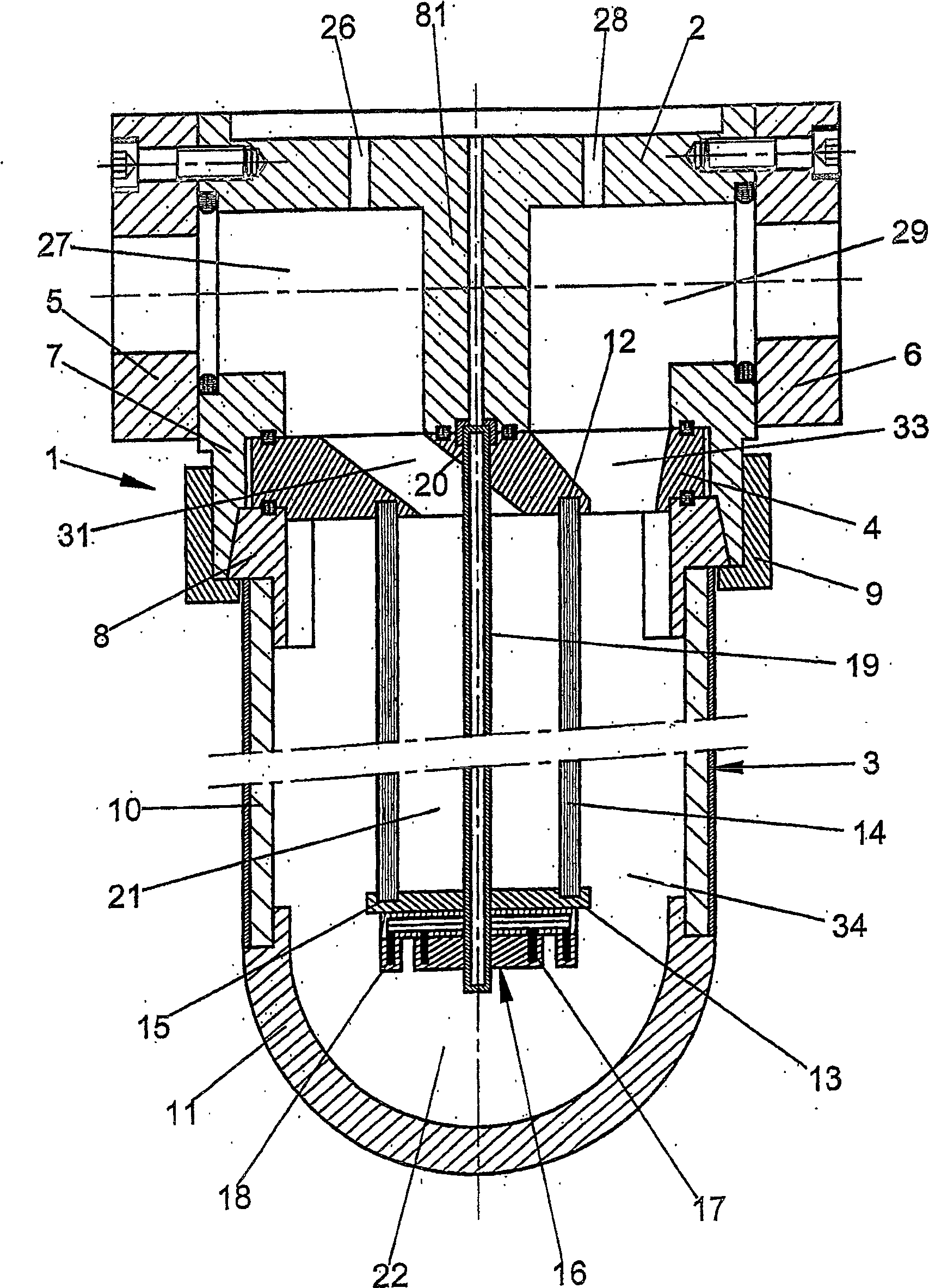

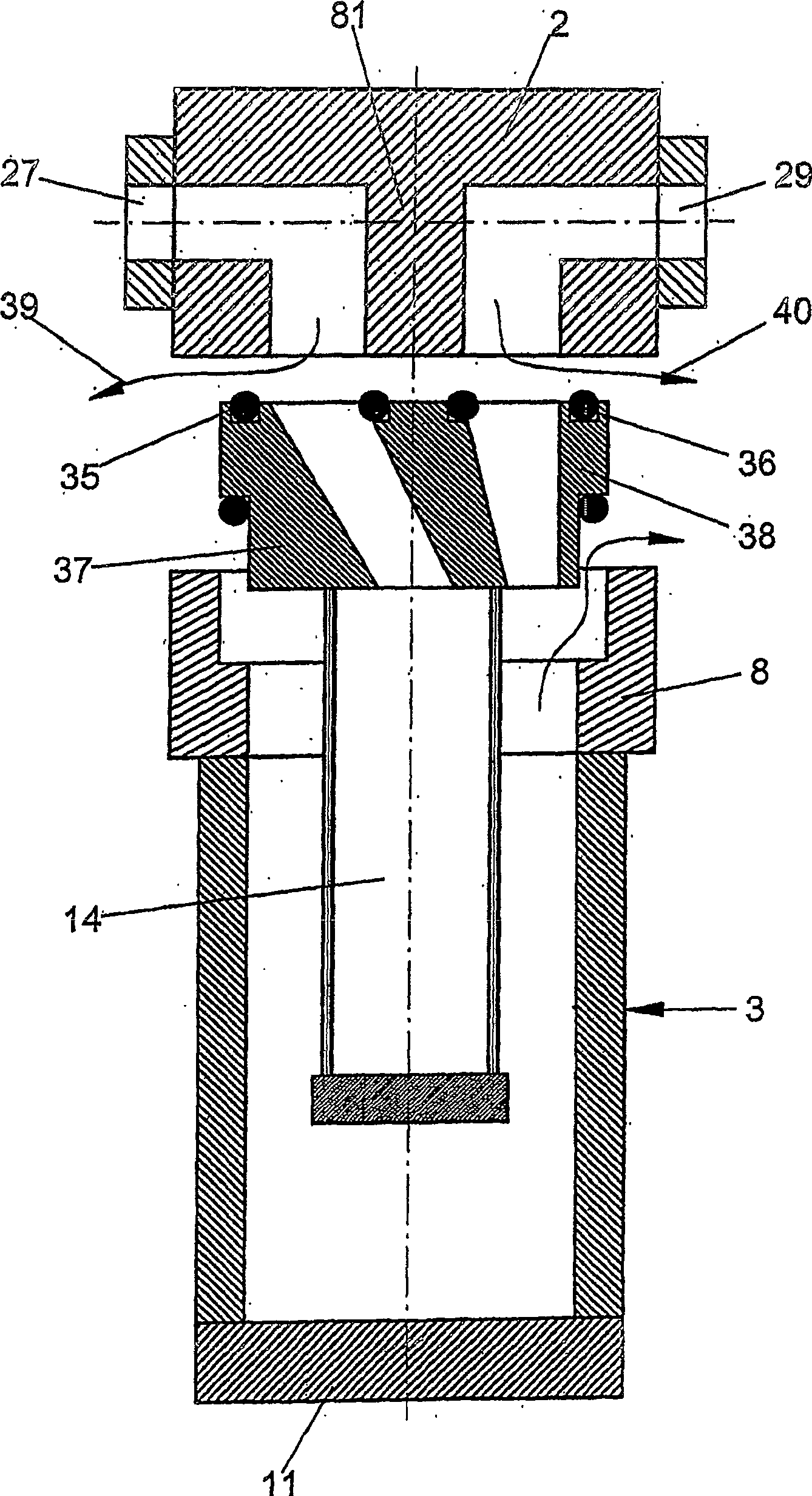

[0033] The shown filter 1 comprises a top 2 and a bottom 3 between which a connecting flange 4 is arranged. The top 2 has two connection adapters 5 , 6 via which the filter 1 can be introduced, for example, into a compressed air line (not shown). The loosely inserted connecting flange 4 is clamped by means of a connecting nut 9 between an inner ring 7 of the top 2 and a connecting ring 8 of the housing. The connecting ring 8 is fixedly connected to a cylindrical central part 10 of the housing, and the central part 10 is connected to a bottom cover 11 .

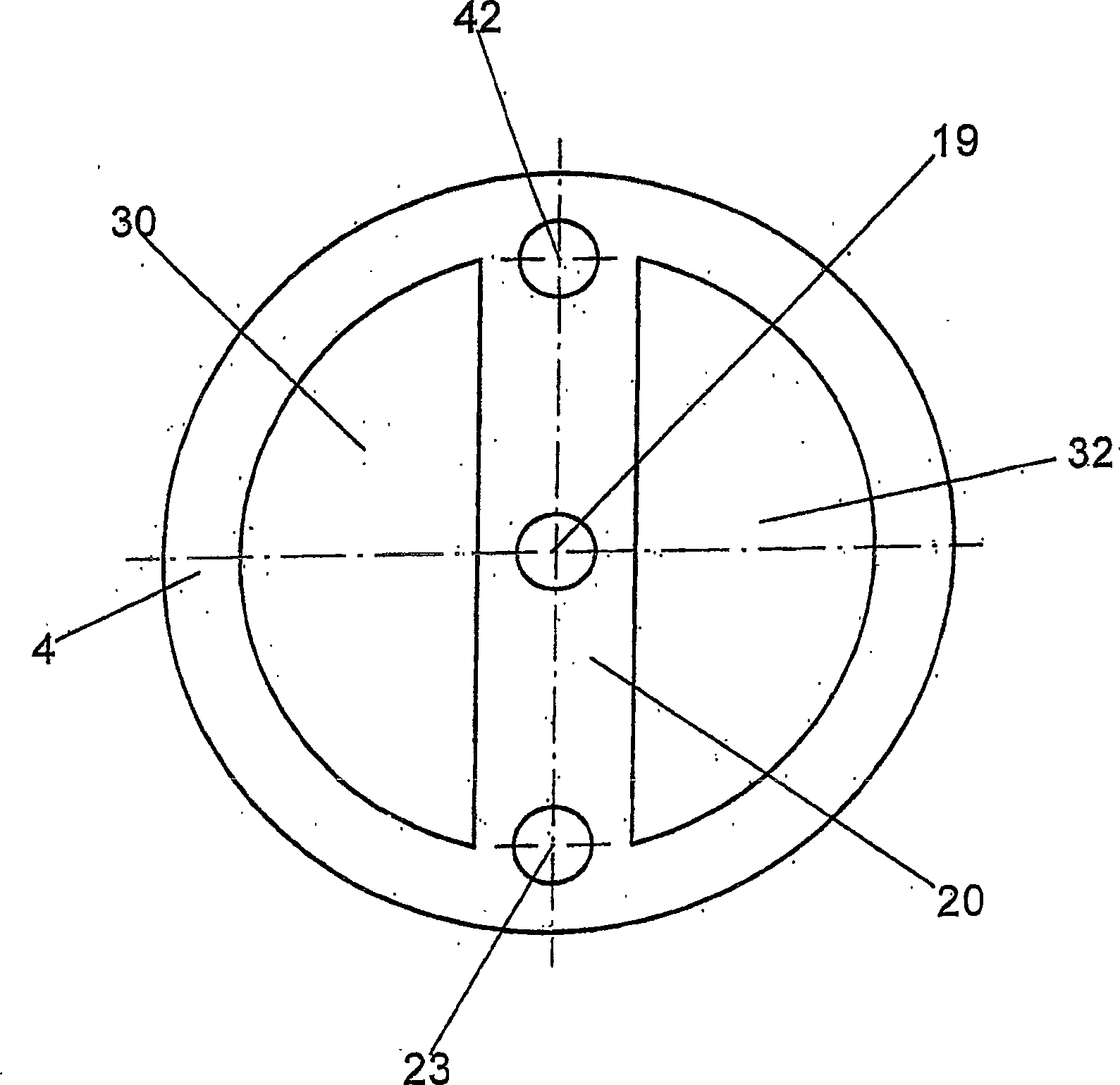

[0034] The upper edge of the hollow cylindrical filter element 14 , which is closed at the bottom by a cover 13 , is clamped in a groove 12 in the connecting flange 4 in a sealing or adhesive manner. The cover 13 likewise has a circumferential groove 15 into which the lower edge of the filter element 14 is glued or clamped. Cover 13 has a capacitive level sensor 16 with two ring electrodes 17 , 18 . A condensation pipe 19 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com