Method for processing stainless steel tube rolling thread

A technology of stainless steel pipes and processing methods, which is applied to threaded products, other household appliances, household appliances, etc., can solve problems such as unfinished ends, poor working environment, and poor thread pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

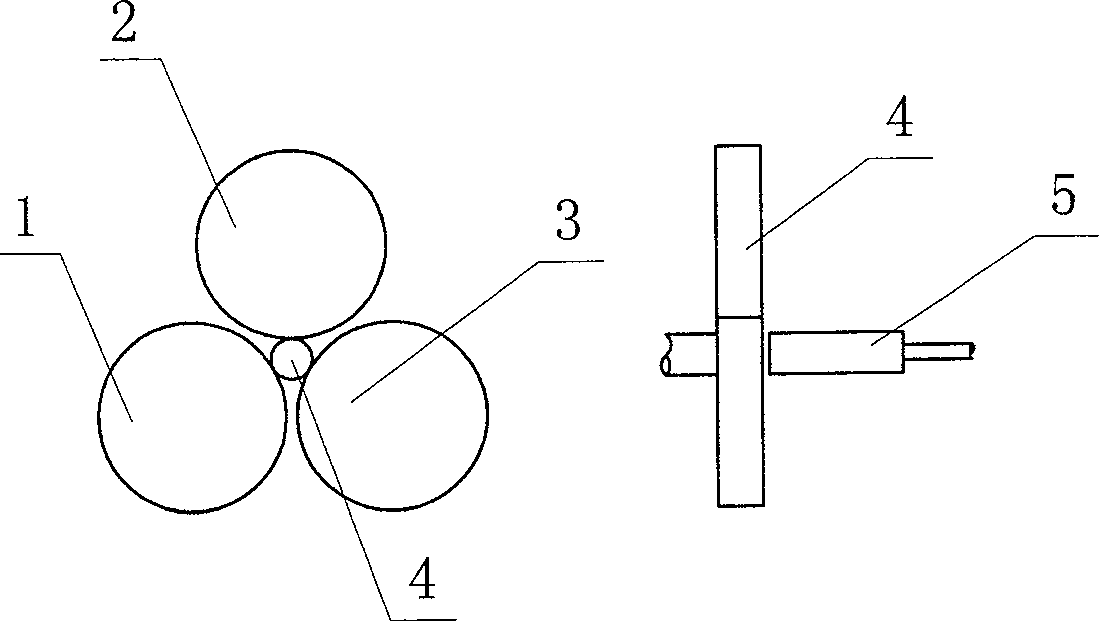

[0020] Example 1, such as Figure 1 to Figure 3 As shown, the stainless steel pipe thread rolling processing method includes the following processes:

[0021] In the first step, the pipeline is cut off, and the stainless steel pipe 4 processed by thread rolling is cut to the corresponding size according to the use requirements;

[0022] The second step is chamfering the pipeline, chamfering the pipe end of the truncated stainless steel pipe 4;

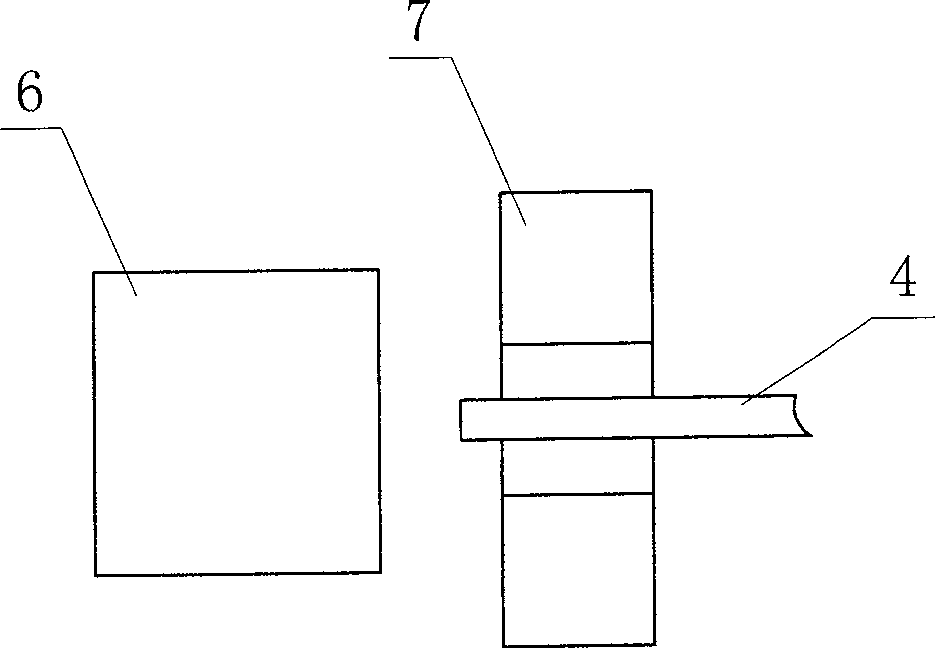

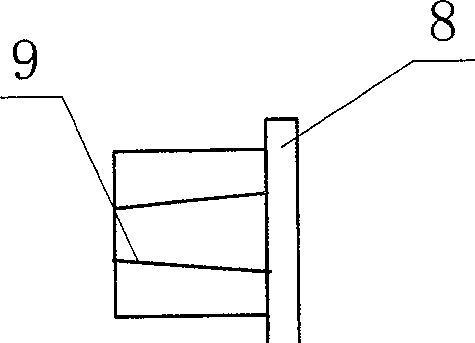

[0023] The third step is to shrink the pipe. Use the hydraulic compression device 7 to compress the pipe end to fix the pipe end between the compression device 7 and the stamping device 6, and use the stamping device 6 to reciprocate on the pipe end to press the pipe end. The pipe end is stamped into the shape of the tapered tube inner chamber 9 of the pipe shrinking die 8, that is, the pipe end after shrinking the pipe is in the shape of a tapered pipe.

[0024] Process the shrinkage taper of the pipe end to the same taper as the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com