Car drive axle semi-axis axletree assembly complete equipment and assembly process

A technology of semi-axis bearings and complete sets of equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as low work efficiency, high labor intensity, and unguaranteed tightening torque of nuts, so as to improve tightening quality and reduce labor Strength, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

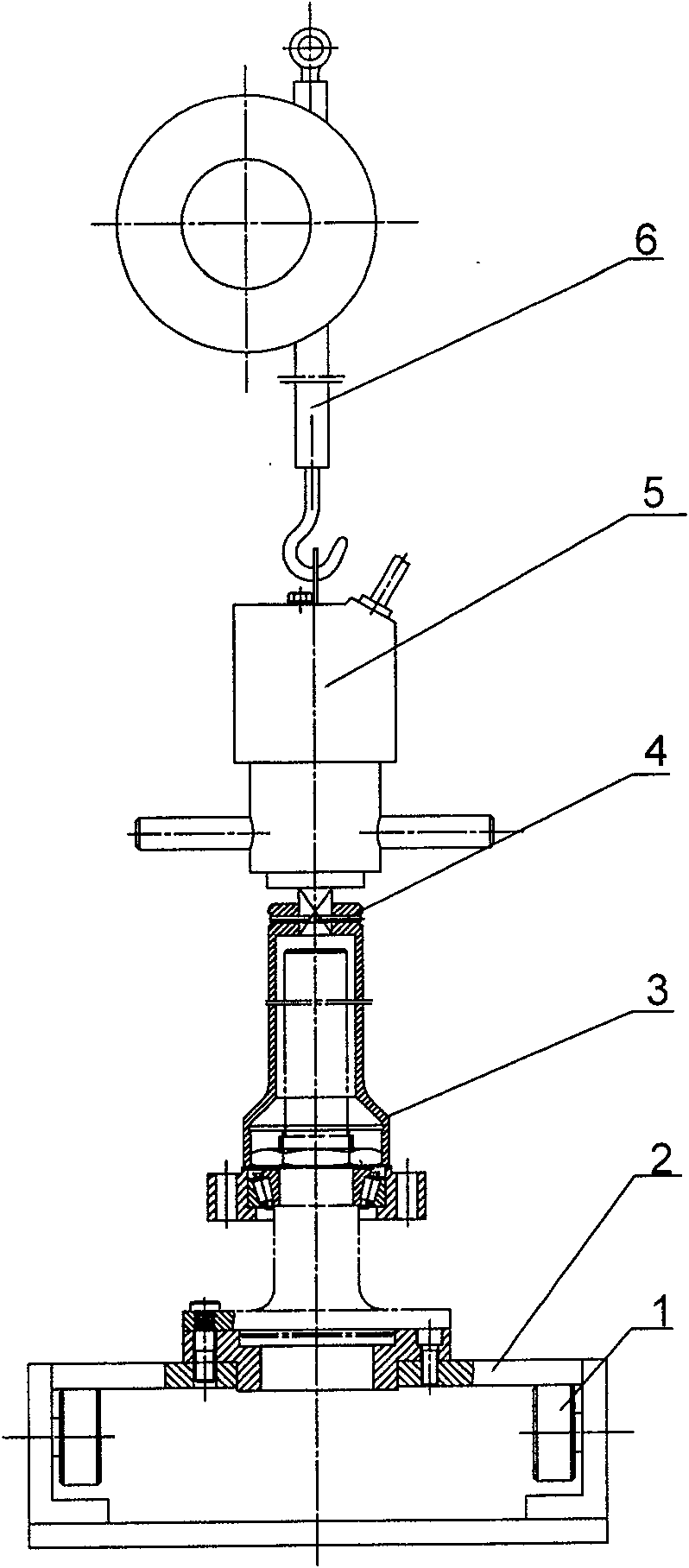

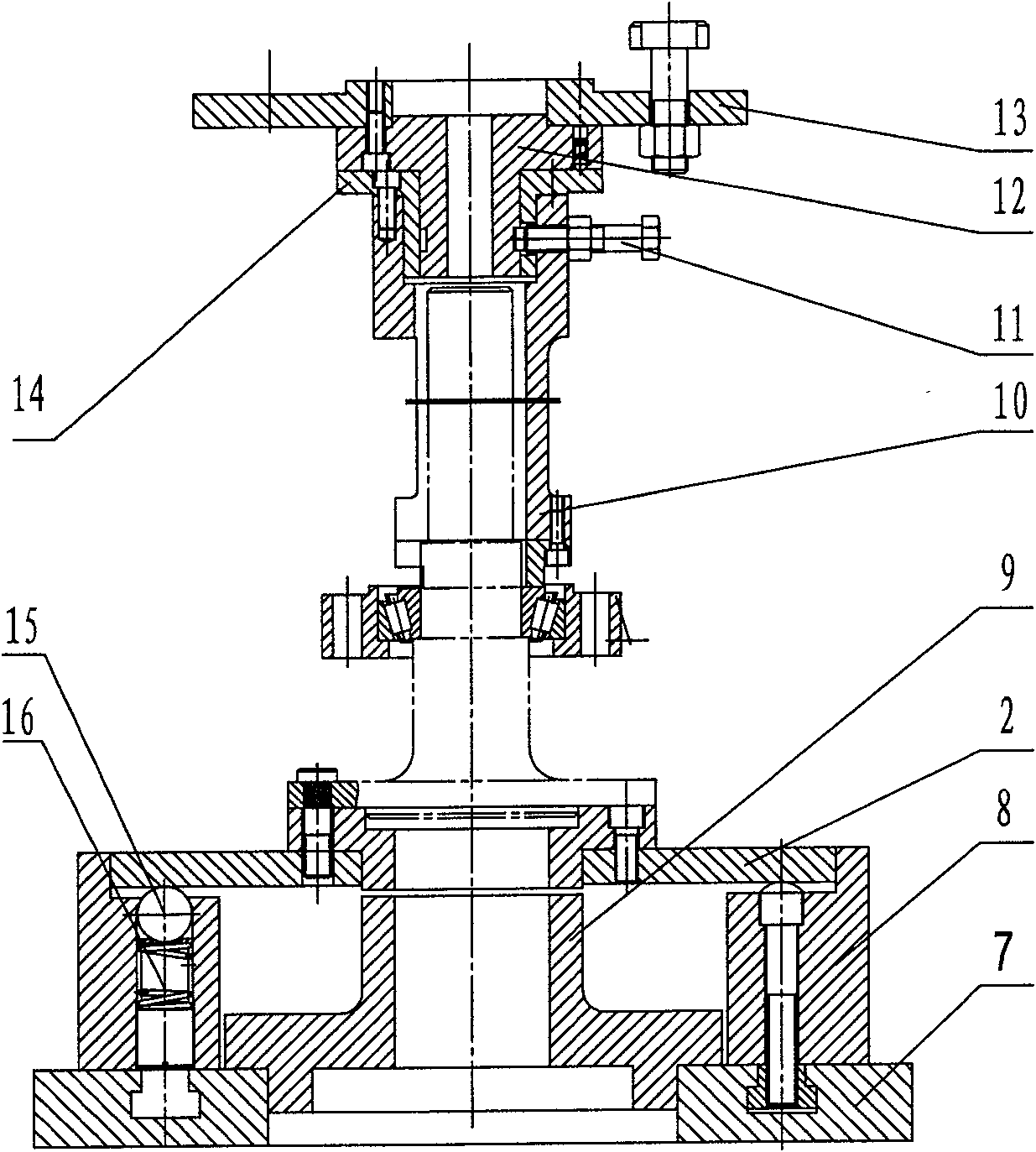

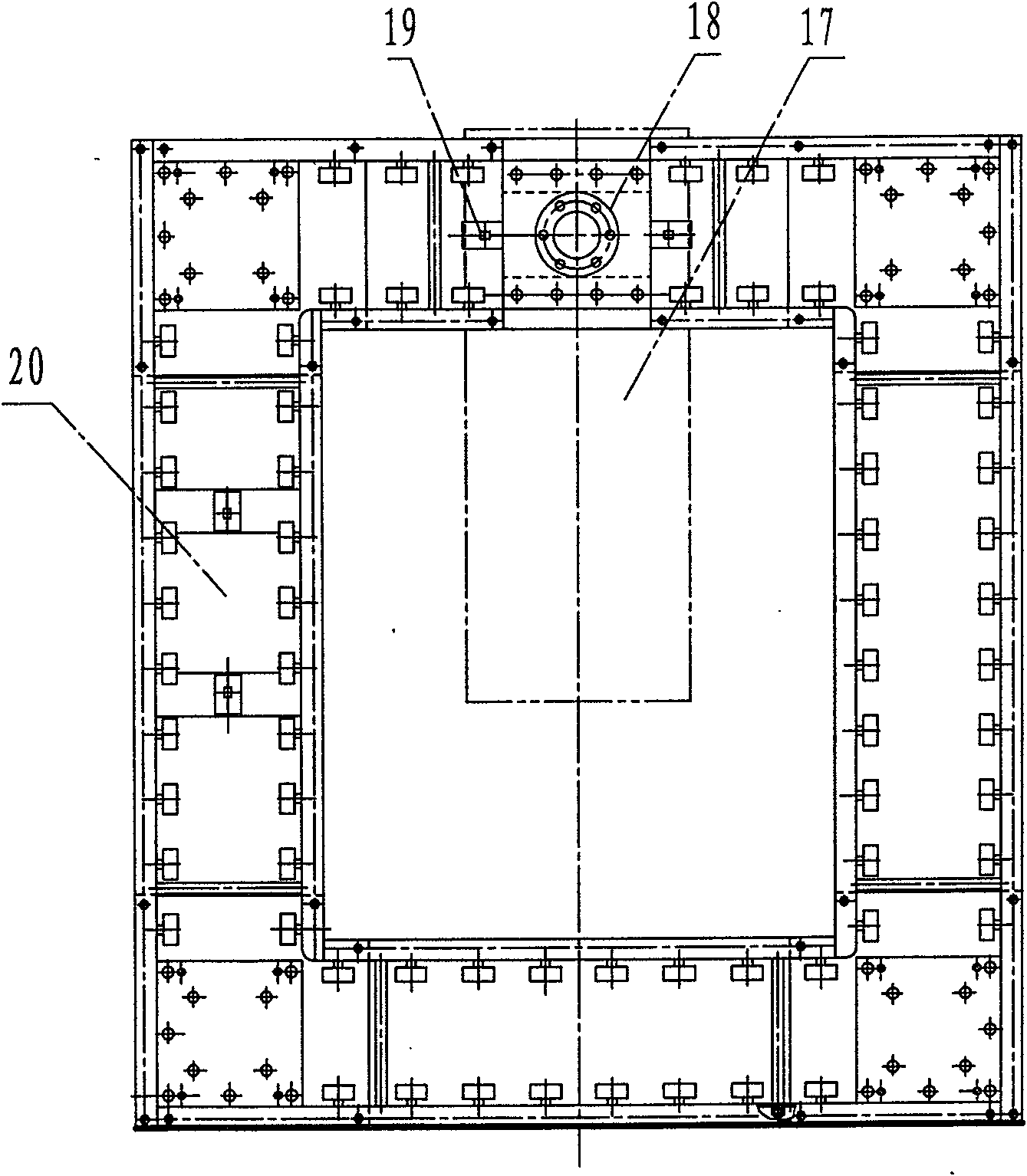

[0014] Example 1: The complete set of equipment for assembly of semi-shaft bearings of automobile drive axles consists of a conveyor line track 1, an elastic track 8, a workpiece pallet assembly 2, a hydraulic press 17, a pressure rod 10, a balancer 6, a constant torque wrench 5 and an extended hexagonal sleeve 3 Composition, the workpiece pallet assembly 2 moves with the elastic track 8 and the conveyor track 1 respectively, and is divided into a bearing pressing station 18 and a bearing nut tightening station 20, and the elastic track 8 and the conveyor track 1 are set correspondingly.

[0015] Bearing press installation station: composed of elastic rail 8, workpiece pallet assembly 2, hydraulic press 17, and pressing rod 10, the pressing rod 10 is connected to the pressure head on the hydraulic press 17 in rotation, the elastic rail 8 is connected to the working table 7 of the hydraulic press, and the workpiece pallet assembly 2 is positioned in the elastic rail 8 by the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com