Thin type large screen back projection TV objection lens for projection

A projection objective lens and large screen technology, applied in the field of projection objective lens, can solve the problems of large distance, increased production cost, and insufficient compact structure, and achieve the effect of high imaging quality, light and thin body, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

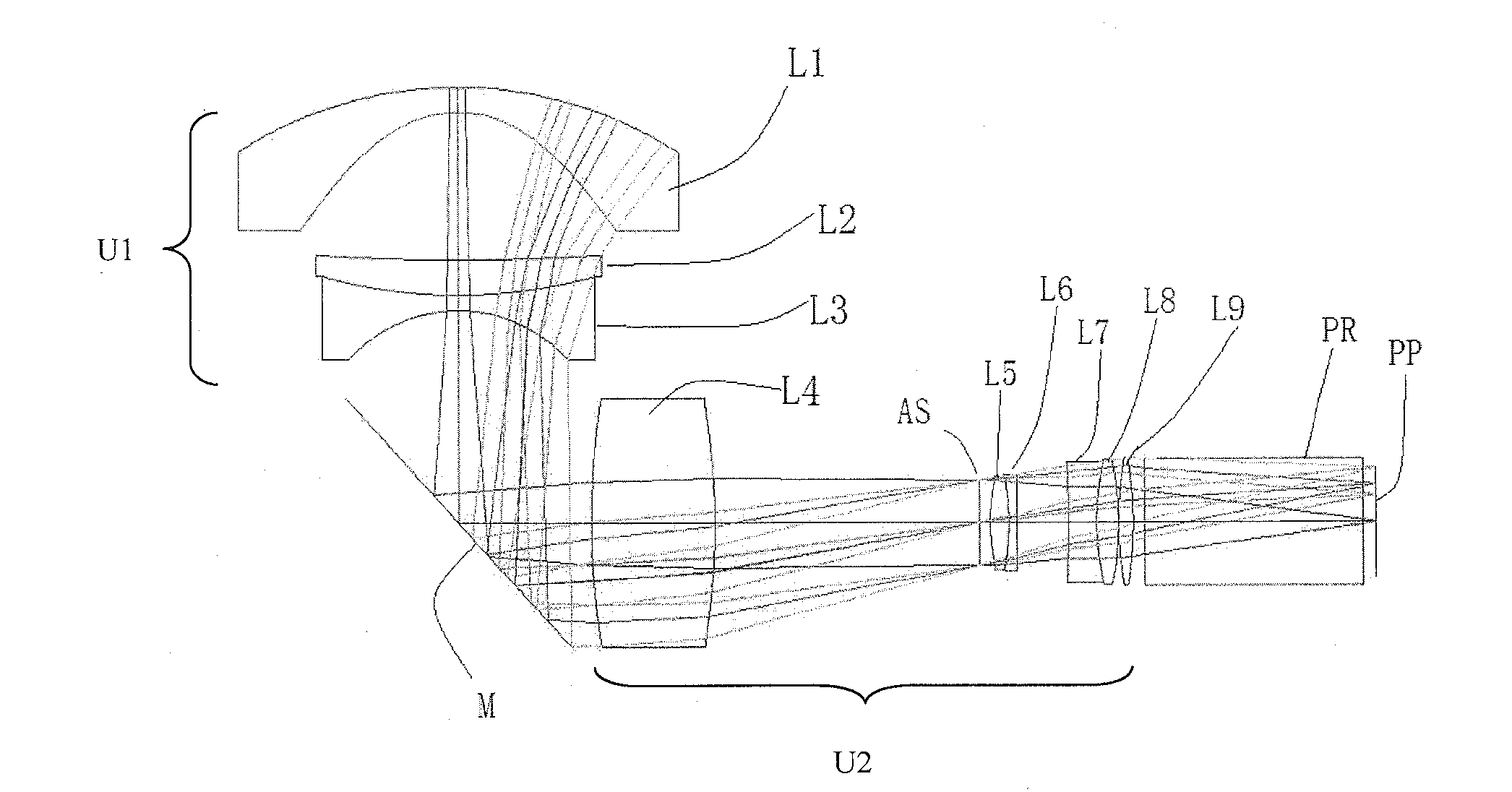

[0028] This embodiment provides a technical solution of a thin large-screen high-definition digital rear-projection television projection objective lens. The optical structure of the objective lens is shown in the appendix figure 1 . In the figure, U1 is the negative power front group, U2 is the positive power rear group, M is a flat mirror, PR is a color combination prism, PP is a pixelated flat plate, L1~L9 are lenses, and L1 and L9 are PMMA Single-sided aspheric lens with stop between L4 and L5.

[0029] Its working bands are 465nm, 550nm, 630nm. The focal length of the objective lens is 8.427mm, the F number F / NO=2.75, and the full field of view 2ω=96 degrees.

[0030] The diagonal of the pixelated flat panel is 0.7", and the diagonal of the projection screen picture is 67".

[0031] The objective lens uses a total of 9 lenses L1-L9, a plane mirror M, and a color combining prism PR. The pixelated flat panel PP is an LCOS microdisplay panel with a pixel size of 8 μm. L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com