Live-working lifting and rotating insulated platform

It is a technology of lifting, rotating and live working, which is applied in the direction of overhead line/cable equipment, etc. It can solve the problems of operator inconvenience, large size, labor and time-consuming equipment erection, etc., to make up for the lack of height, reduce storage and transportation volume, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

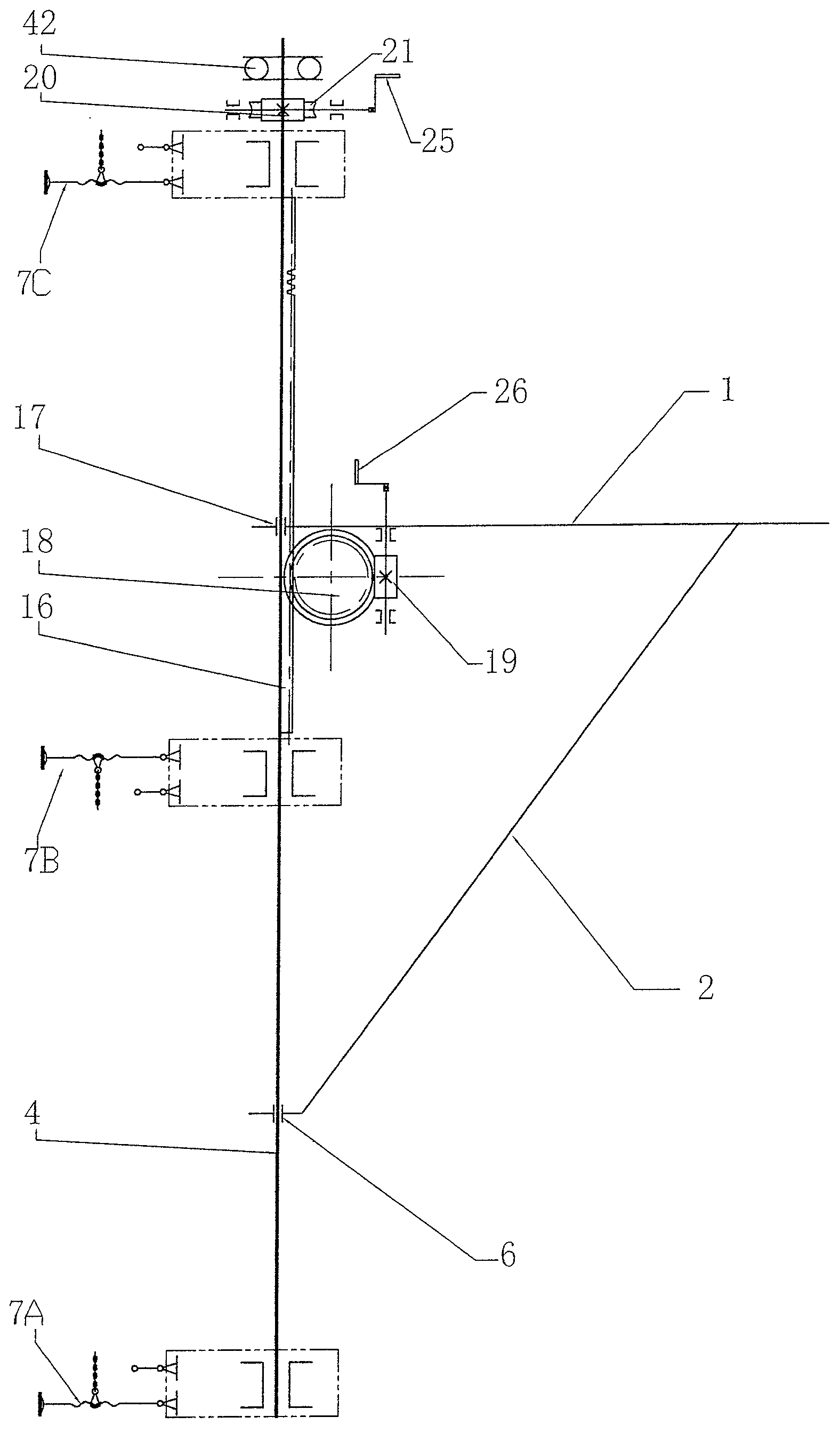

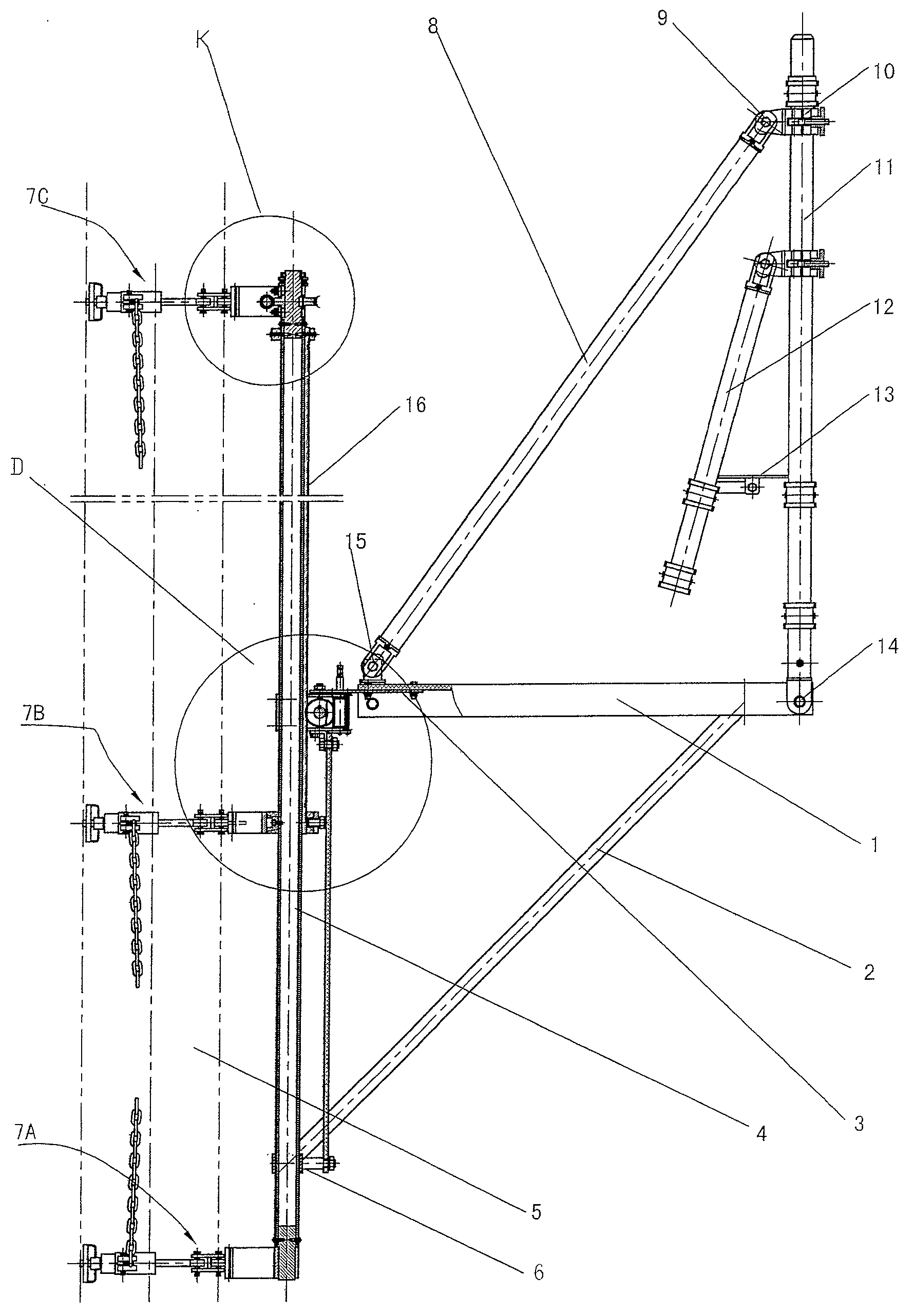

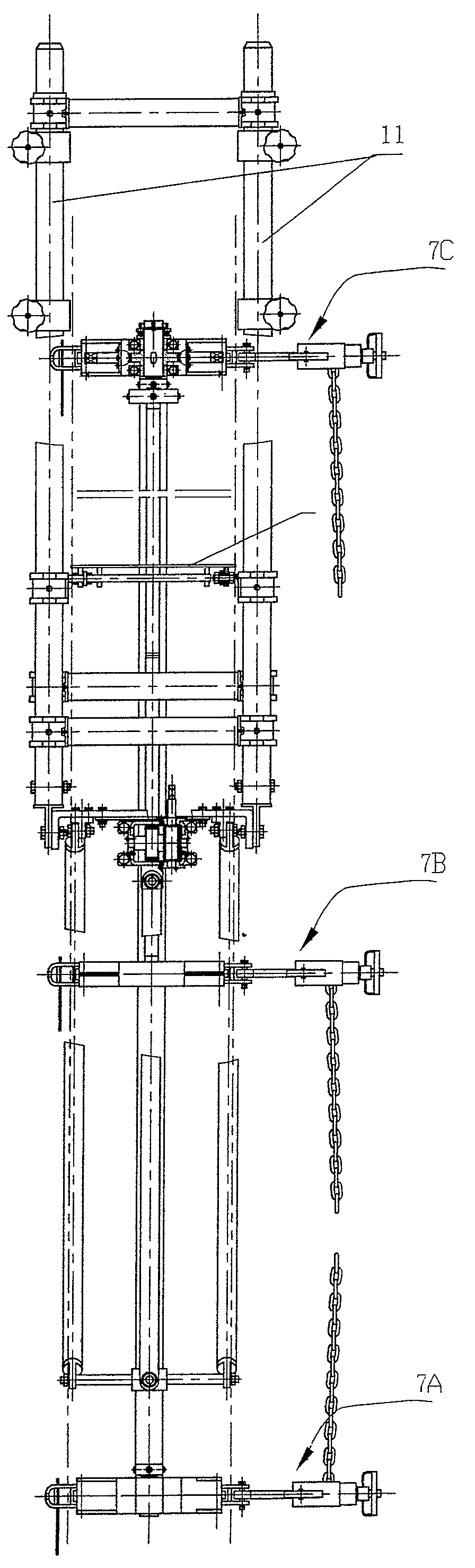

[0020] refer to figure 1 , figure 2 , image 3 , a lifting and rotating insulating platform for live work, a vertical pole 4 composed of a rectangular tubular section, the upper, middle and lower ends of which are respectively rotatable with the upper, middle and lower hoops 7C, 7B and 7A for holding the utility pole 5 Connected, the outer rod surface of the vertical rod 4 is tightly fixed to the tooth bar 16 by the support sleeve of the screw 44 and the middle hoop 7B. The inner side of the insulating platform 1 is connected with the upper sliding sleeve 17 set on the vertical pole, and is equipped with a worm gear pair, wherein the worm 19 is a driving shaft, which can be shaken by a handle 26, or driven by a DC motor, and the worm gear 18 and the rack 16 Engaging, turning the handle 26 can drive the insulating platform device to move up and down along the vertical rod 4 . The outer end of insulating platform 1 is hinged with the sliding sleeve 6 that is enclosed within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com