Circulating fluidized bed boiler multiple-point return feeder

A technology of circulating fluidized bed and feeder, applied in the field of high temperature circulating material return device, can solve the problems of difficult expansion design, easy occurrence of expansion sealing, affecting operation safety, etc., and achieves flexible design, avoids deformation and leakage, and simplifies The effect of expansion seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

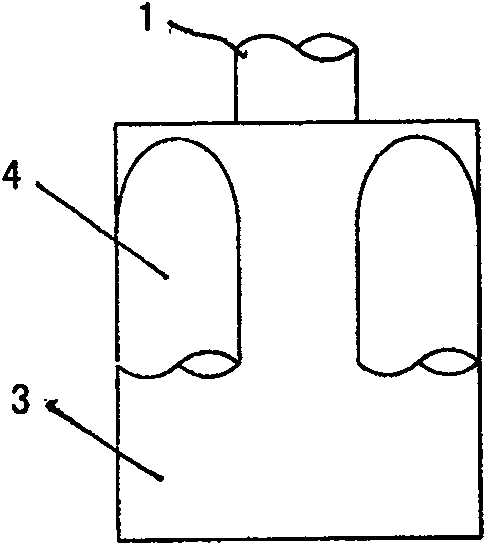

[0018] Such as figure 1 , 2 , 3 and 4 show embodiment 1, the multi-point feeder of circulating fluidized bed boiler, comprising a cylindrical descending section 1, a cuboid rising section 3, and a horizontal section 2 connecting the two bottoms, its transverse The cross-section is approximately isosceles trapezoidal; the cross-section of the ascending section 3 is rectangular, and its long side is perpendicular to the direction of the horizontal symmetry axis of the horizontal section 2, and the ratio of the cross-sectional area of the ascending section 3 to the cross-sectional area of the descending section 1 is 3.6; Two return sections 4 that are connected to each other with two overflow ports 31 on the top of the rising section 3, and the heights of the two overflow ports 31 are equal; these two return sections 4 are symmetrical to each other with the symmetry plane of the return device, and their centerlines are mutually symmetrical. Parallel, the outlets all point d...

Embodiment 2

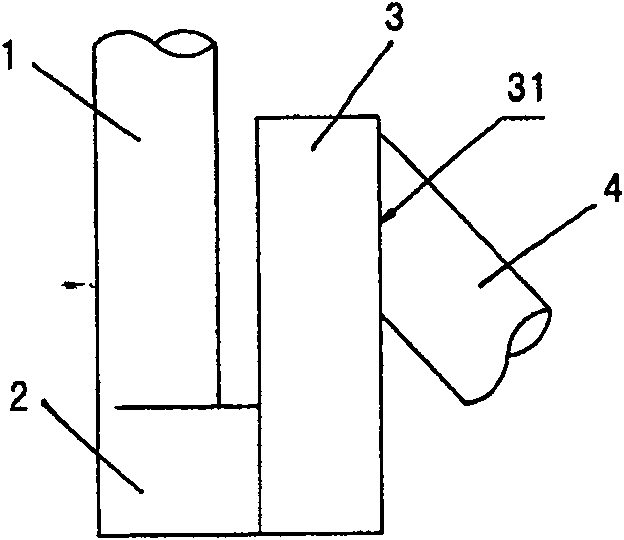

[0020] Such as Figure 5 , 6 Shown in and 7 are embodiment 2, the multi-point feeder of circulating fluidized bed boiler, comprising a cylindrical descending section 1, a cuboid rising section 3, and a horizontal section 2 connecting the two bottoms, whose cross section is approximately Isosceles trapezoidal; the cross-section of the ascending section 3 is a rectangle, and its long side is perpendicular to the direction of the horizontal symmetry axis of the horizontal section 2, and the ratio of the cross-sectional area of the ascending section 3 to the cross-sectional area of the descending section 1 is 2; The return section 4 connected to the overflow port 31 on the upper part of the ascending section 3 has its center lines parallel to each other, and the outlets all point to the furnace 10; the center line of one of the return sections 4 is located on the symmetric plane of the return device, and the other two are in the form of return The planes of symmetry of the de...

Embodiment 3

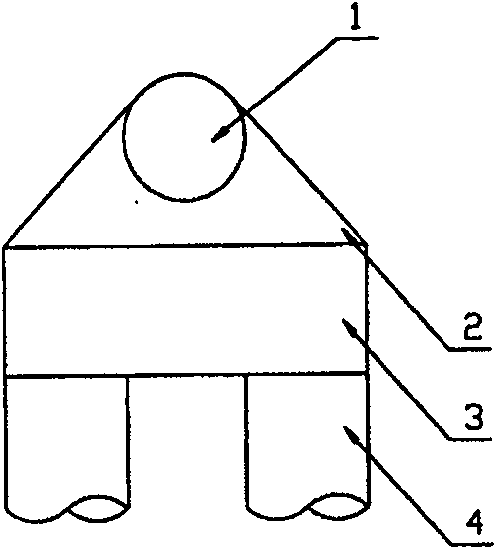

[0022] Such as Figure 8 , 9 Shown in and 10 is embodiment 3, the multi-point feeder of circulating fluidized bed boiler, comprising a cylindrical descending section 1, a columnar ascending section 3, and a nearly rectangular parallelepiped horizontal section 2 connecting the two bottoms; The cross-section of the ascending section 3 is oblong, and its long side is perpendicular to the symmetry plane of the feeder, and the ratio of the cross-sectional area of the ascending section 3 to the descending section 1 is 1; the upper part of the ascending section 3 has two overflow ports 31 , which are located at both ends of the cross-section width direction of the rising section 3, that is, at the two circular ends; the centerlines of the two return sections 4 connected to the overflow port 31 are on the same plane, and are symmetrical to the symmetry plane of the return section , the outlets point downwards in two opposite directions respectively, and communicate with the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com