Photomask used for color filter technology

A color filter and photomask technology, applied in the field of photomask, can solve the problems of high repeatability, manufacturing cost, waste of labor, offset and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

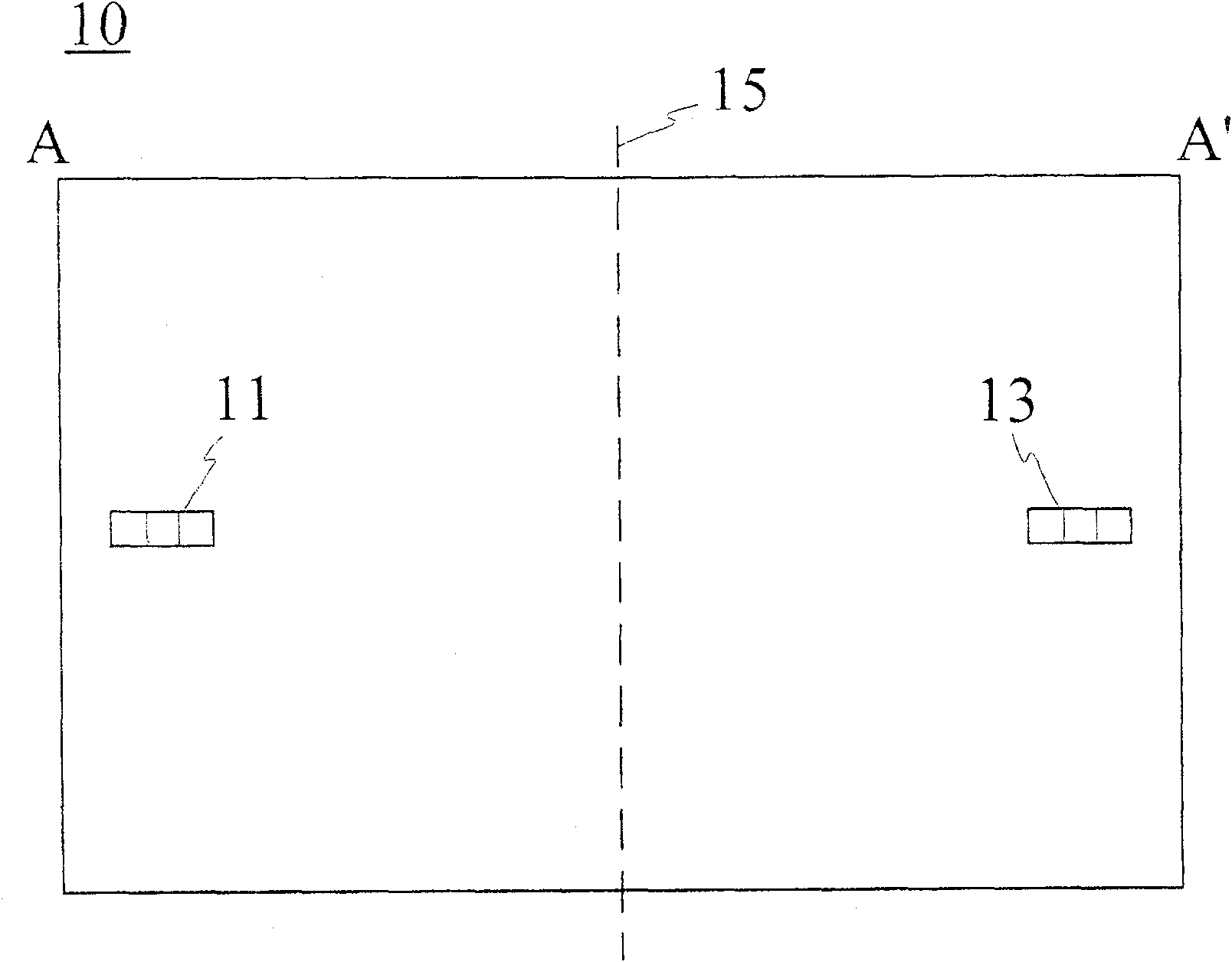

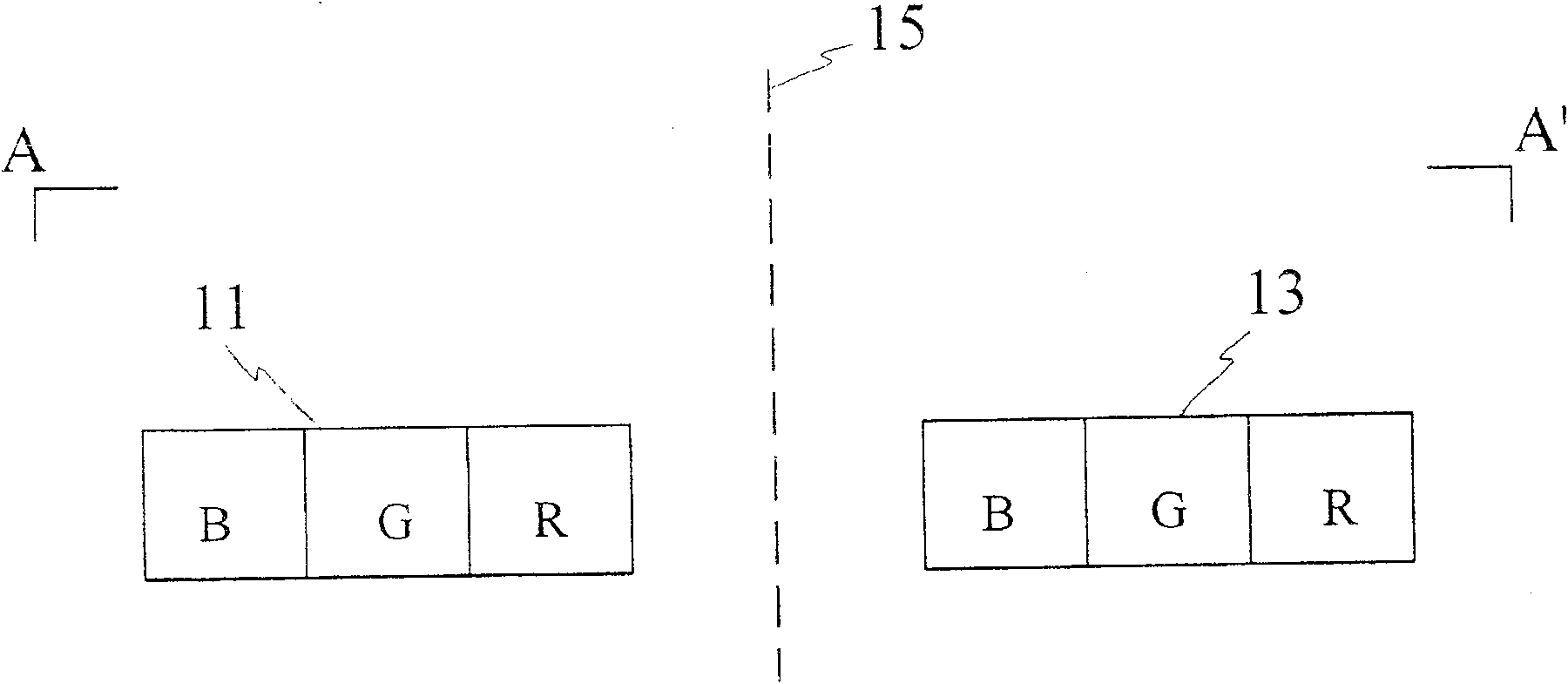

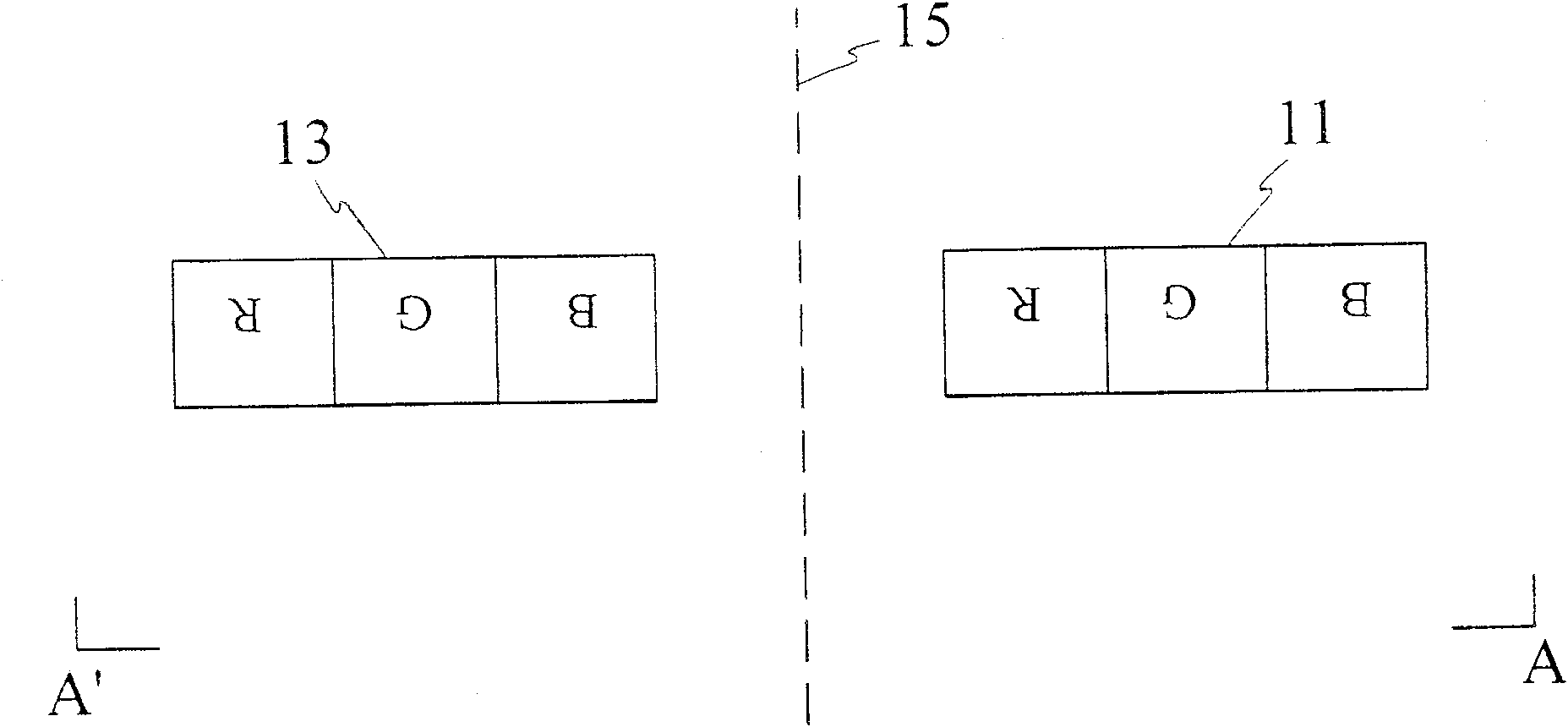

[0039] The first embodiment of the present invention is as Figure 4 As shown, a photomask 30 for color filter process is disclosed. A reference symmetry axis 40 is set on the photomask 30. The symmetry axis can be an actual symmetry axis or a virtual reference symmetry axis 40; It has a center of symmetry 41 . The photomask 30 further includes a first alignment mark 31 and a second alignment mark 31', which are substantially symmetrical to each other with respect to the reference axis of symmetry 40 and the center of symmetry 41. In this embodiment, the first alignment mark 31 and the second alignment mark 31' are preferably substantially horizontally symmetrical with respect to the reference axis of symmetry 40 .

[0040] It should be noted that, the first alignment mark 31 and the second alignment mark 31' in this embodiment are not limited to horizontal symmetry, but can also be substantially obliquely symmetrical (not shown). Furthermore, as long as the first alignment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com