Transistor of low temperature polysilicon thin film and producing method

A technology of thin-film transistors and low-temperature polysilicon, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effect of improving process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

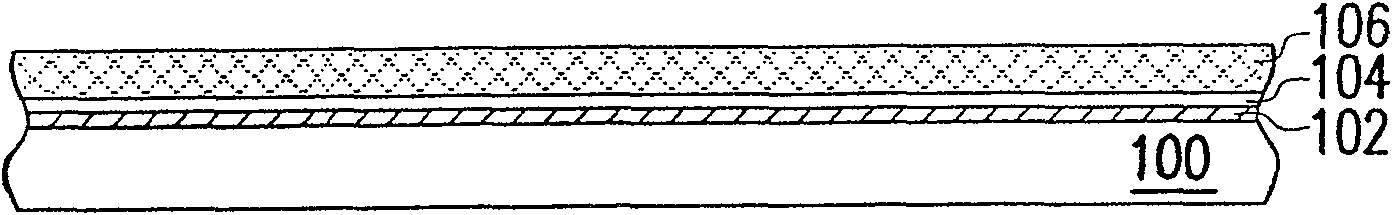

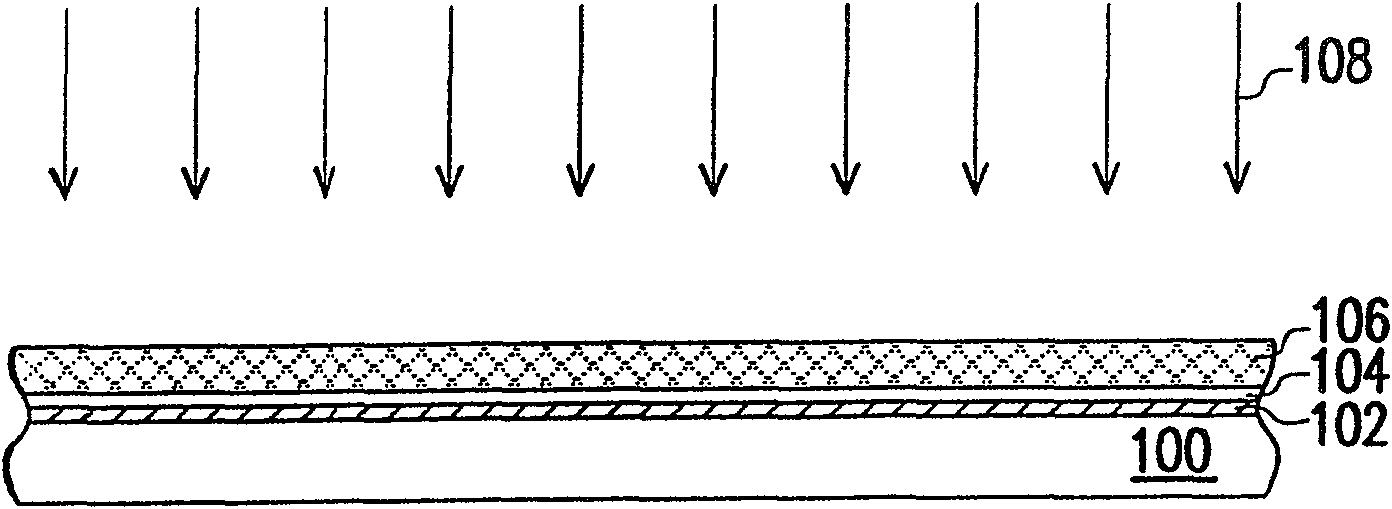

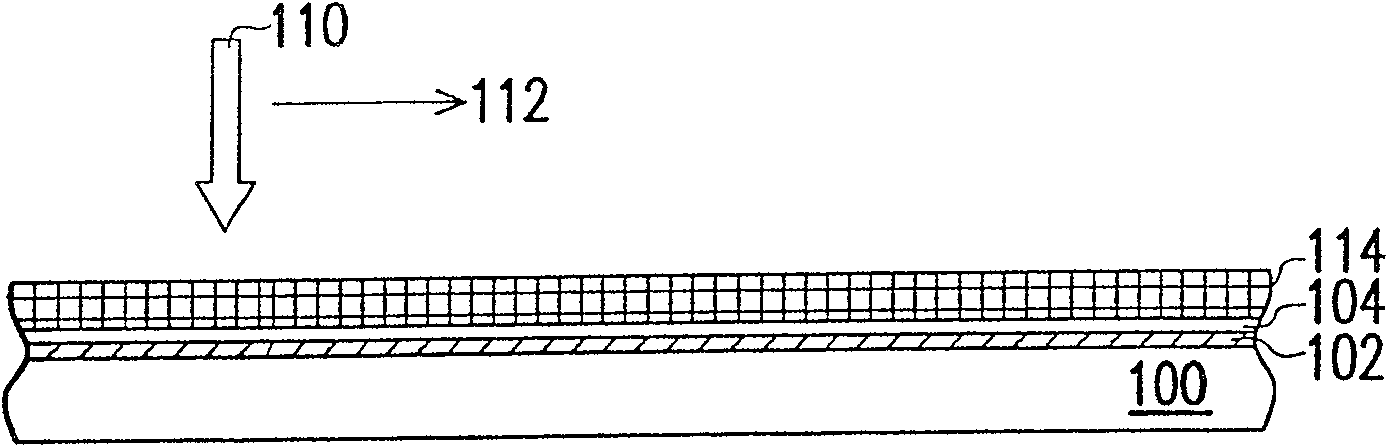

[0035] Figure 1A to Figure 1J It is a sectional view of the manufacturing process of a low temperature polysilicon (low temperature poly-Si, LTPS for short) thin film transistor (thin film transistor, TFT for short) according to a preferred embodiment of the present invention.

[0036] Please refer to Figure 1A First, selectively form a buffer layer (buffer layer) on the substrate 100, wherein the buffer layer is, for example, a stack layer composed of a silicon nitride layer 102 and a silicon oxide layer 104, and its function is to improve the connection between the substrate 100 and the subsequently formed The adhesion of the polysilicon layer and when there are metal ions such as sodium in the substrate 100 are used to prevent the metal ions in the substrate 100 from contaminating the polysilicon layer. Then, an amorphous silicon (a-Si) layer 106 is formed on the silicon oxide layer 104 .

[0037] Then, please refer to Figure 1B , perform a plasma treatment (plasma tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com