High pressure pump for a fuel injection device of an internal combustion engine

一种燃料喷射装置、高压泵的技术,应用在用于内燃机的燃料喷射装置的高压泵领域,能够解决润滑特性恶化、不能保证高压泵寿命等问题,达到改善抗摩擦性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

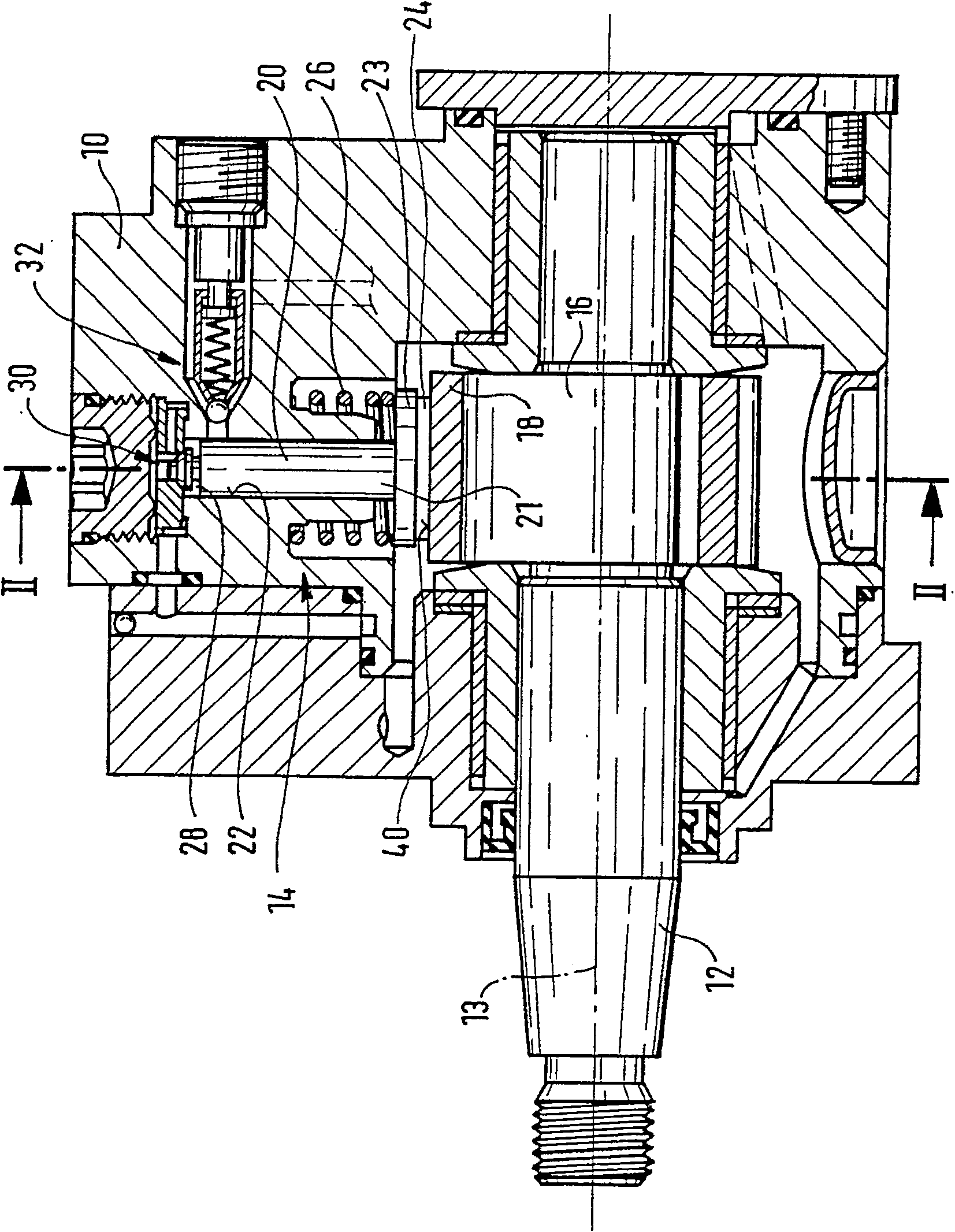

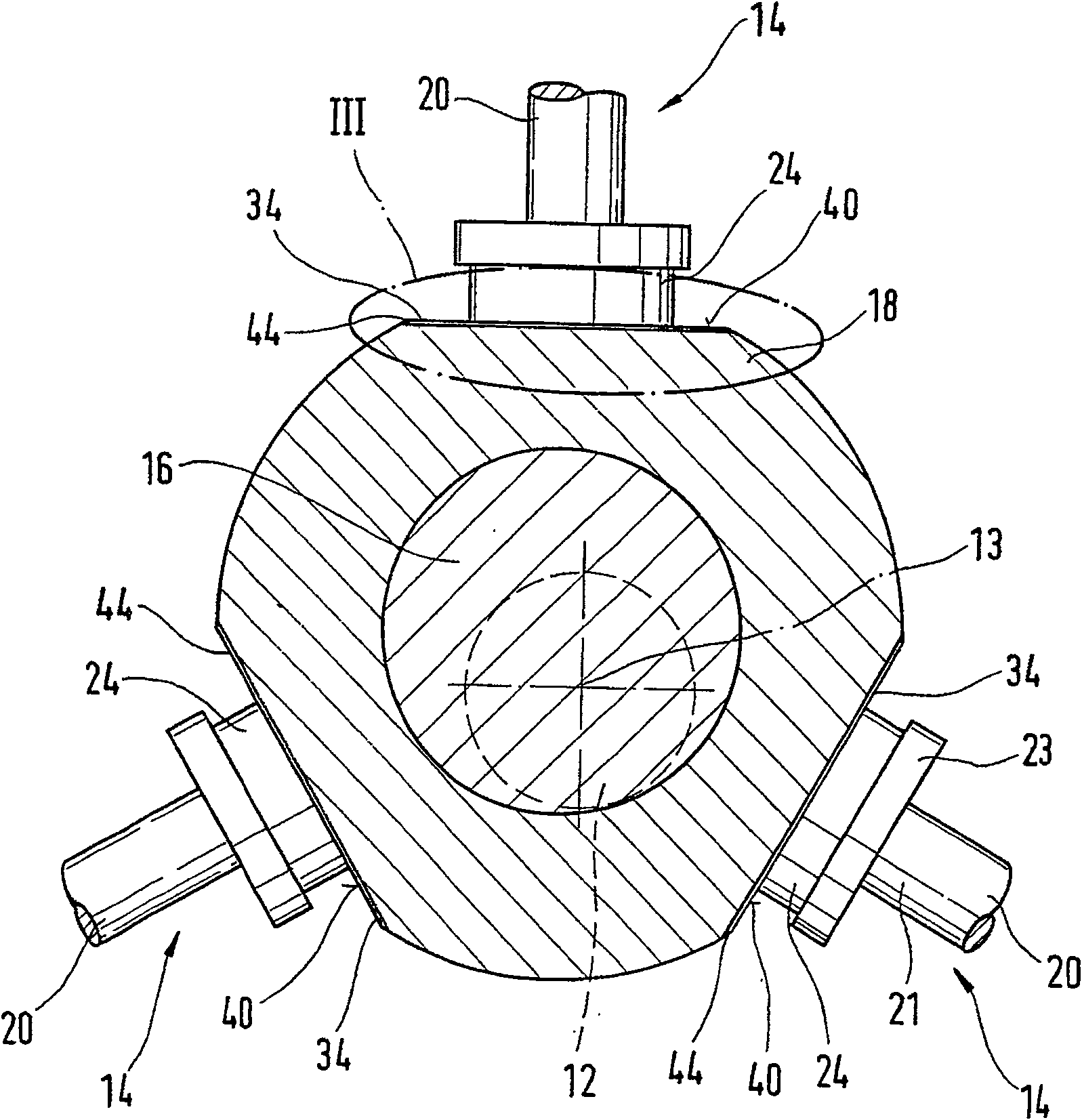

[0012] exist Figures 1 to 6 shows a high-pressure pump for a fuel injection system of an internal combustion engine of a motor vehicle, for example, which is designed as a radial piston pump. Via the high-pressure pump, fuel is delivered at a high pressure of up to 2000 bar into, for example, a storage tank, from which the fuel is withdrawn for injection into the internal combustion engine. The high-pressure pump has a housing 10 in which a drive shaft 12 is mounted rotatably about an axis 13 . At least one, preferably a plurality of pump elements 14 , which are driven by the drive shaft 12 , are accommodated in the housing 10 . The drive shaft 12 has a shaft section 16 configured eccentrically to its axis of rotation 13 , on which a ring 18 is rotatably mounted. The pump elements 14 each have a pump plunger 20 , which is guided displaceably and sealingly in a cylinder bore 22 extending at least approximately radially to the axis of rotation 13 of the drive shaft 12 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com