Dry-running piston compressor

A piston type and compressor technology, which is applied to the arrangement of pumps/compressors, liquid displacement machinery, mechanical equipment, etc., can solve the problems of damaged compressors, large size, and inability to provide running time of piston compressors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

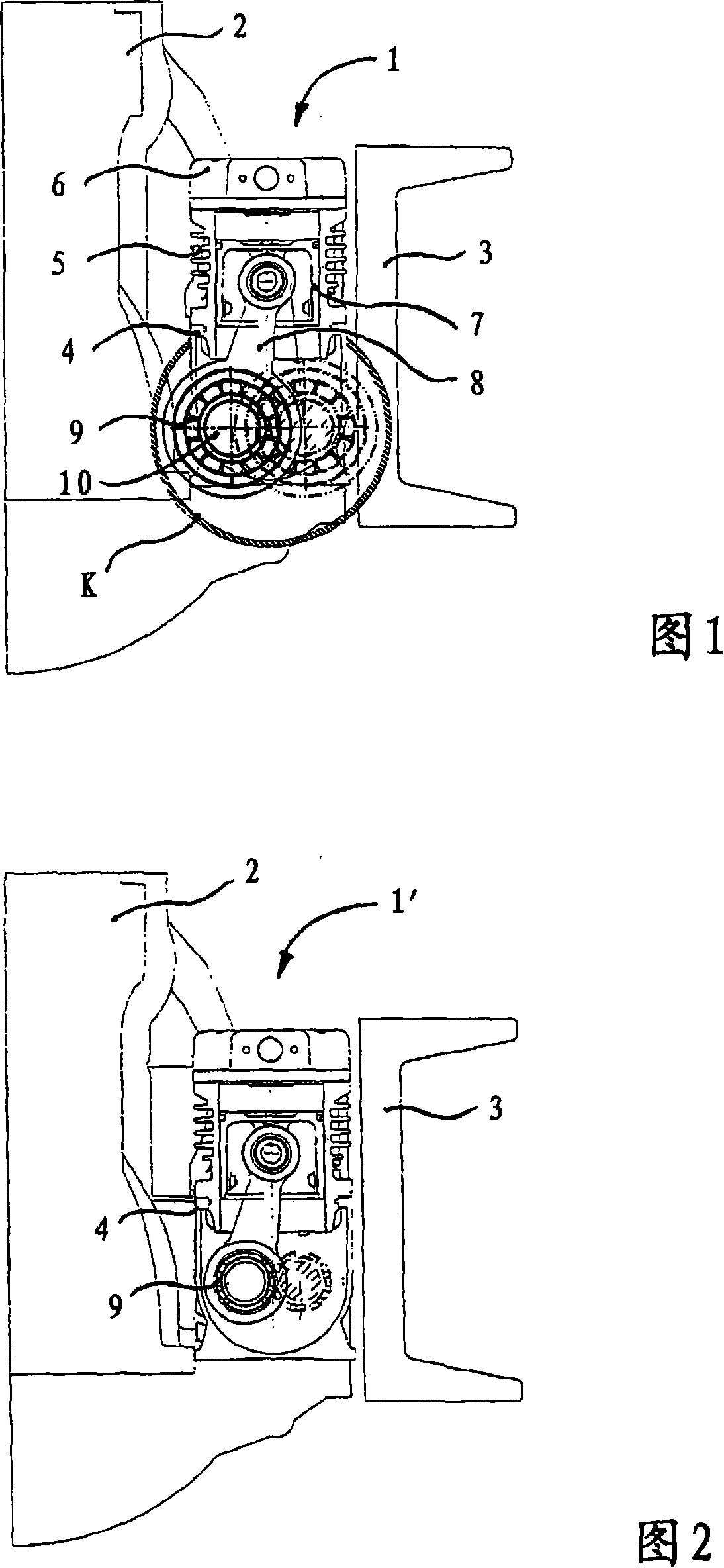

[0030] According to FIG. 1 , a piston compressor 1 is arranged in a commercial vehicle or rail vehicle (not shown further here) between an engine 2 for driving the vehicle and a support frame 3 . The engine 2 used to drive the vehicle is also used to drive the piston compressor 1 .

[0031] The piston compressor 1 has a crankcase 4 on which a pot-shaped cylinder 5 is mounted via a screw connection (not shown further here). The pot-shaped cylinder 5 is provided with a cylinder head 6 through which, in a known manner, air is sucked in from the environment and the compressed air generated in the cylinder 5 is discharged via the integrated valve arrangement here.

[0032] A reciprocating piston 7 is provided in the cylinder 5 for generating compressed air. The piston 7 is mounted rotatably on a connecting rod 8 and is connected at the opposite end to the crankshaft 10 via a connecting rod bearing 9 .

[0033] In this exemplary embodiment, which corresponds to the prior art, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com