Curved face arch shape traverse baffle shell type heat exchanger

A baffle and heat exchanger technology, which is applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of difficult installation of bow-shaped baffles, unfavorable industrial standardization, and difficulty in ensuring accuracy. Achieve the effect of increasing the heat transfer film coefficient and effective heat exchange area, increasing the effective flow area and reducing the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

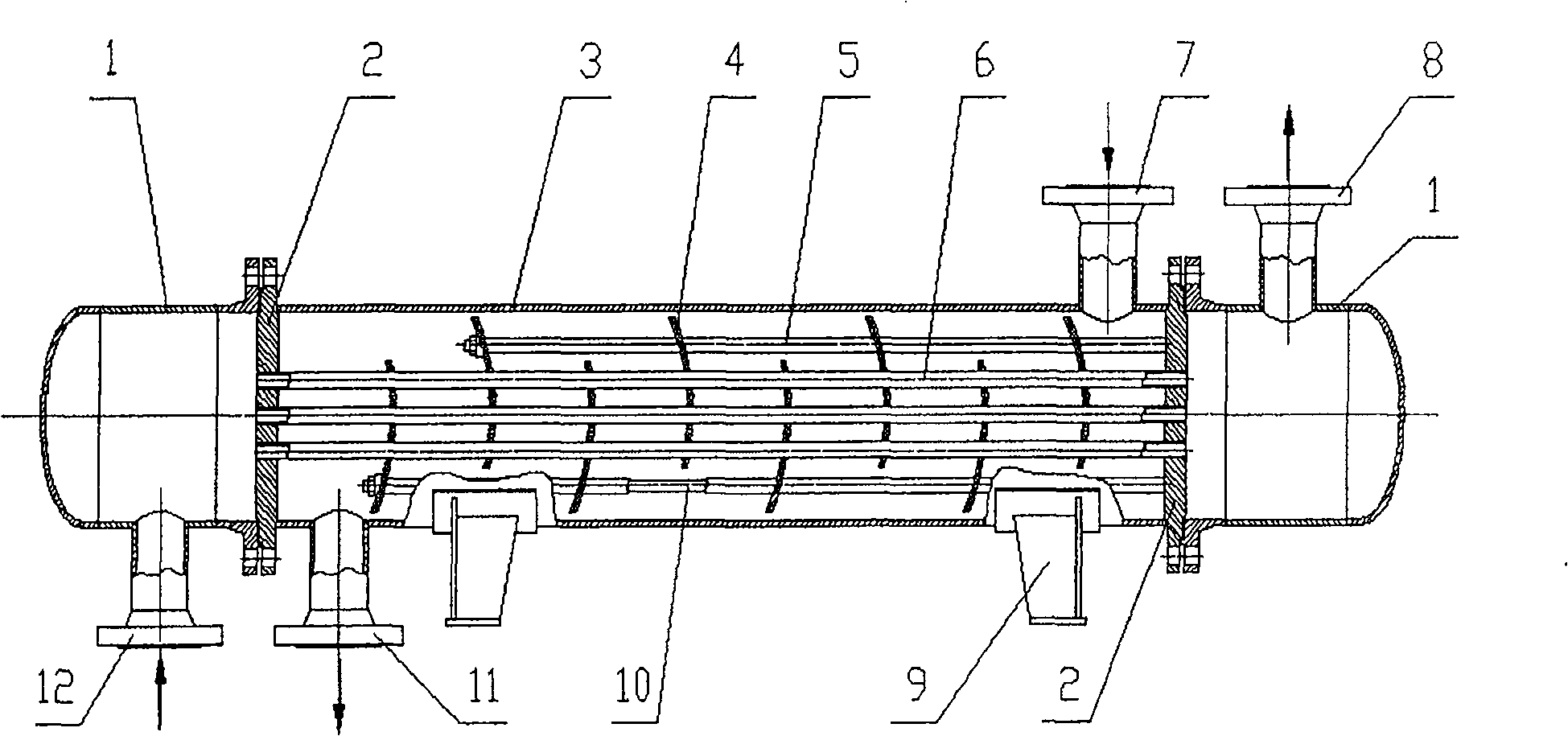

Embodiment 1

[0014] For fixed tubesheet heat exchangers used in petrochemical refineries, the heat exchange medium tube-side fluid is water, the inlet temperature is 20°C, the shell-side fluid is C6 oil, and the inlet temperature is 120°C. The inner diameter of the shell is 800mm; the heat exchange tube is φ25×2, the number of which is 490, passing through 8 arc-shaped arcuate baffles, the axes are fixed on the tube plates at both ends in parallel, and the radius of the arc surface of the baffles is 800mm , the thickness of the baffle is 10mm, the notch of the bow-shaped baffle is staggered horizontally and vertically, and the distance between the baffle is 660mm, forming a circuitous flow channel for fluid up and down in the cylinder. After heat exchange, the temperature of C6 oil drops to 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com