Spherical netted shell combined structure

A technology of combined structure and ball net, applied in truss structure, building structure, joist and other directions, can solve the problems of cable bridge length should not be too large, the construction process is complicated, the construction cost is increased, etc., and the construction workload can be reduced. , Wide applicability, the effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

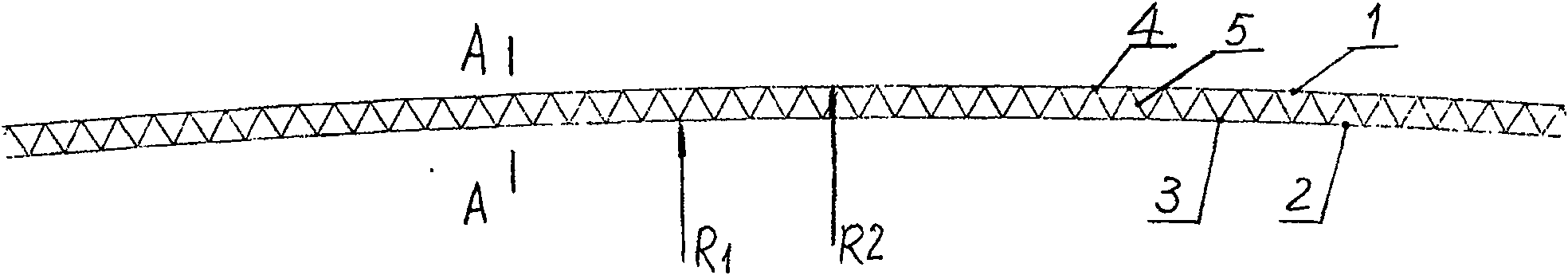

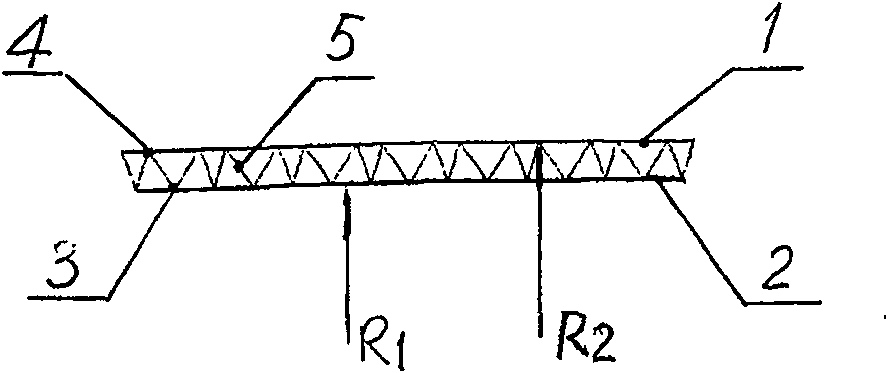

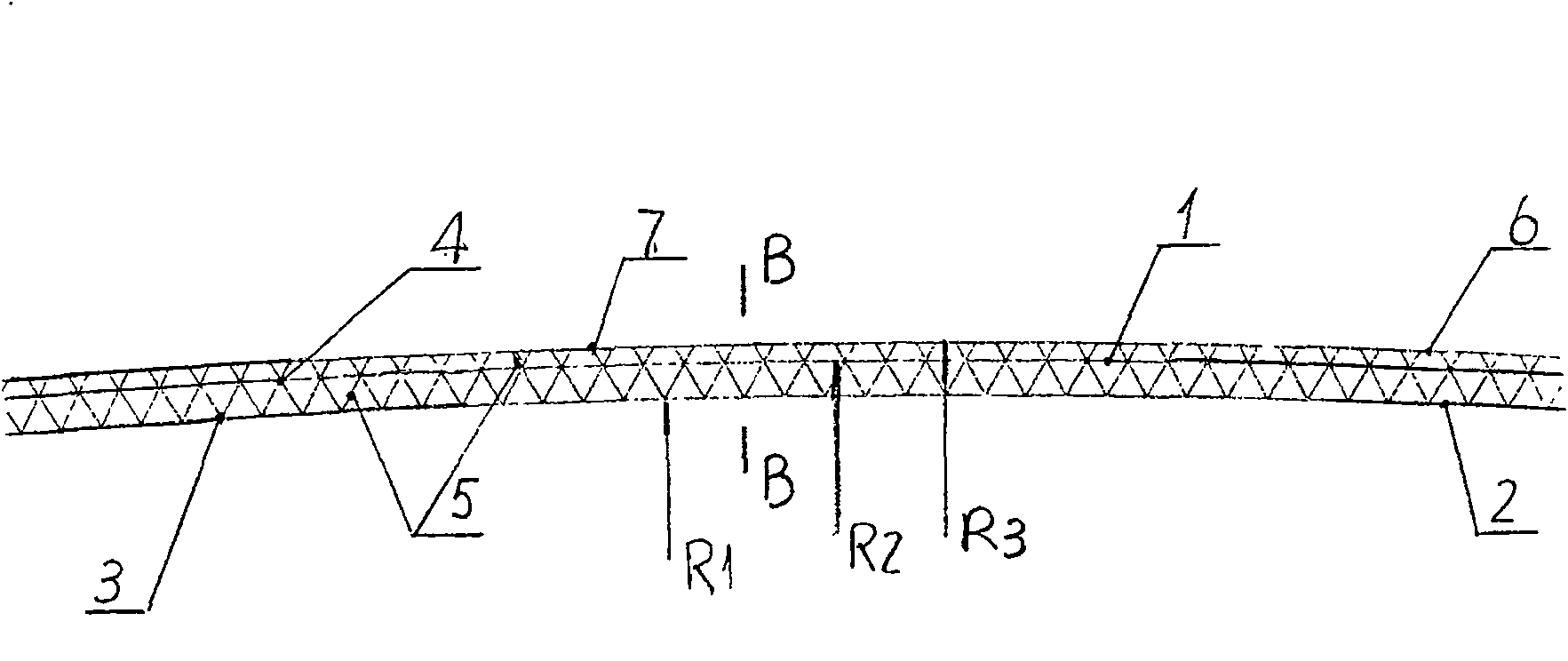

[0022] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A ball net shell composite structure, the hexagonal grid-shaped upper layer assembled by the upper chord 1 and the hexagonal grid-shaped lower layer assembled by the lower chord 2 are spherical in shape, and the upper spherical surface and the lower layer The spherical surface is two different diameters R of concentric spheres 2 and R 1 The upper spherical surface is located above the lower spherical surface; the upper chords 1 of the upper spherical surface are connected through the upper node 4, and the lower chords 2 of the lower spherical surface are connected through the lower node 3. The upper chord 5 of the web , and the lower end are respectively connected with the upper node 4 and the lower node 3 to form a double-layer reticulated shell. Above the hexagonal grid-like upper spherical surface formed by the top chord 1, the hexagonal gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com