Spiral module type assembled casing heat exchanger

A combined casing and heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problems of declining competitiveness of enterprises, rising manufacturing costs, and declining profits of enterprises. Improve heat transfer effect, increase flow rate, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

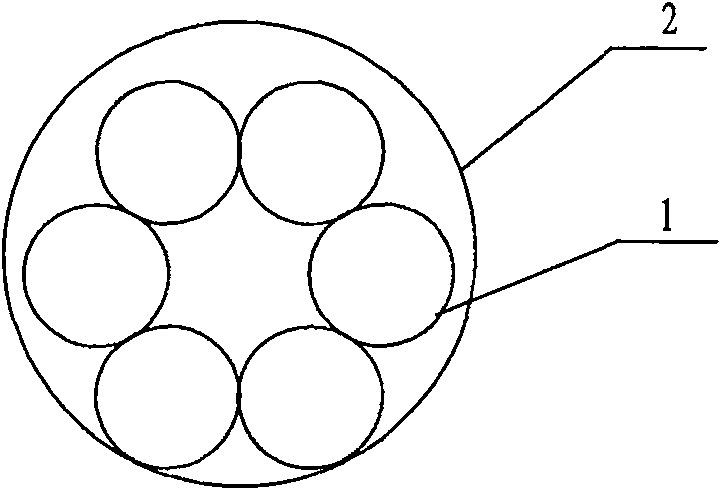

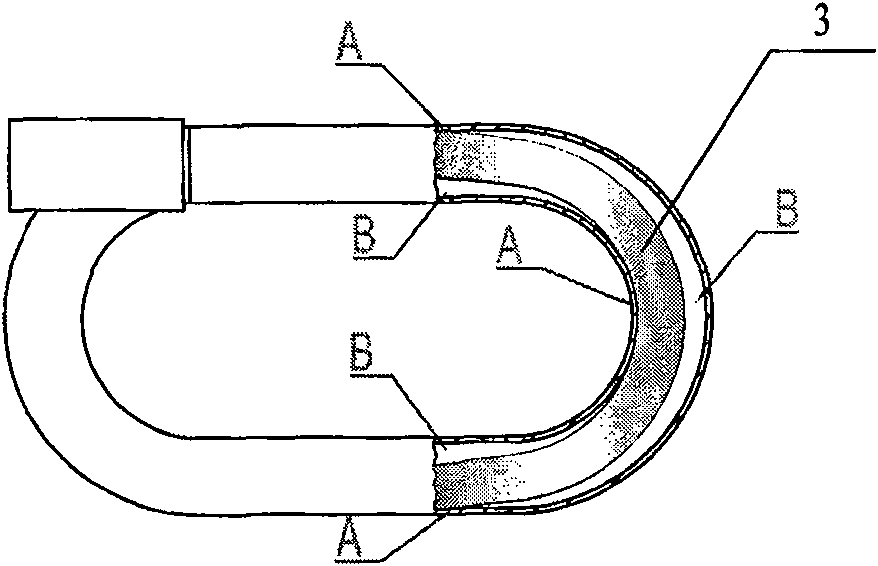

[0023] Figure 5 It is a schematic diagram of the cross-sectional structure of the combined casing heat exchanger in Embodiment 1 of the present invention. As shown in the figure, the casing heat exchanger includes two spiral modules 2, and two casing pipes 3 are arranged in the spiral modules 2 respectively. Firstly, two casing pipes 3 are intertwined with each other over the full length, and then put into the spiral module 2 , and the two spiral modules 2 formed in this way are intertwined with each other over the entire length, and put into the heat exchanger tube bundle 1 .

Embodiment 2

[0025] Figure 6 It is a schematic diagram of the cross-sectional structure of the combined casing heat exchanger in Example 2 of the present invention. As shown in the figure, the casing heat exchanger includes two spiral modules 2, and two casing pipes 3 are arranged in the spiral modules 2 respectively. First, the two sleeves 3 are intertwined with each other over the full length, and then put into the spiral module 2, the two spiral modules 2 formed in this way are intertwined with the two sleeves 3 over the entire length, and put into the heat exchanger tube bundle within 1.

Embodiment 3

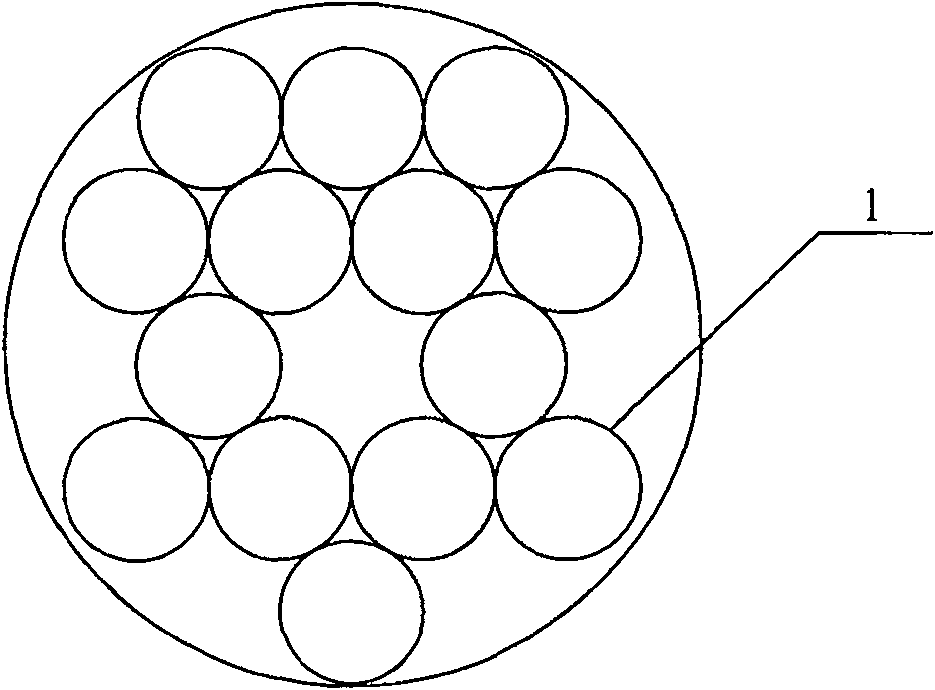

[0027] Figure 7 It is a schematic diagram of the cross-sectional structure of the combined casing heat exchanger in Embodiment 3 of the present invention. As shown in the figure, the casing heat exchanger includes three spiral modules 2, and three casing pipes 3 are arranged in the spiral modules 2 respectively. Firstly, the three casing pipes 3 are intertwined with each other over the full length, and then put into the spiral module 2 , and the three helical modules 2 formed in this way are intertwined with each other over the entire length, and put into the heat exchanger tube bundle 1 .

[0028] The helical direction of the helical module 2 of the present invention is opposite to the helical direction of the casing 3 .

[0029] To achieve turbulent flow, it is necessary to achieve the proper Reynolds number, high-speed flow, increased resistance, and increased power consumption. The present invention can achieve a lower flow rate and rely on the internal structure to prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com