Method for preparing octadecyl amine/kaolin inserted layer composition

An intercalation compound, kaolin technology, applied in silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unstable product performance, and achieve the effects of easy industrial production, stable performance, and easier acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

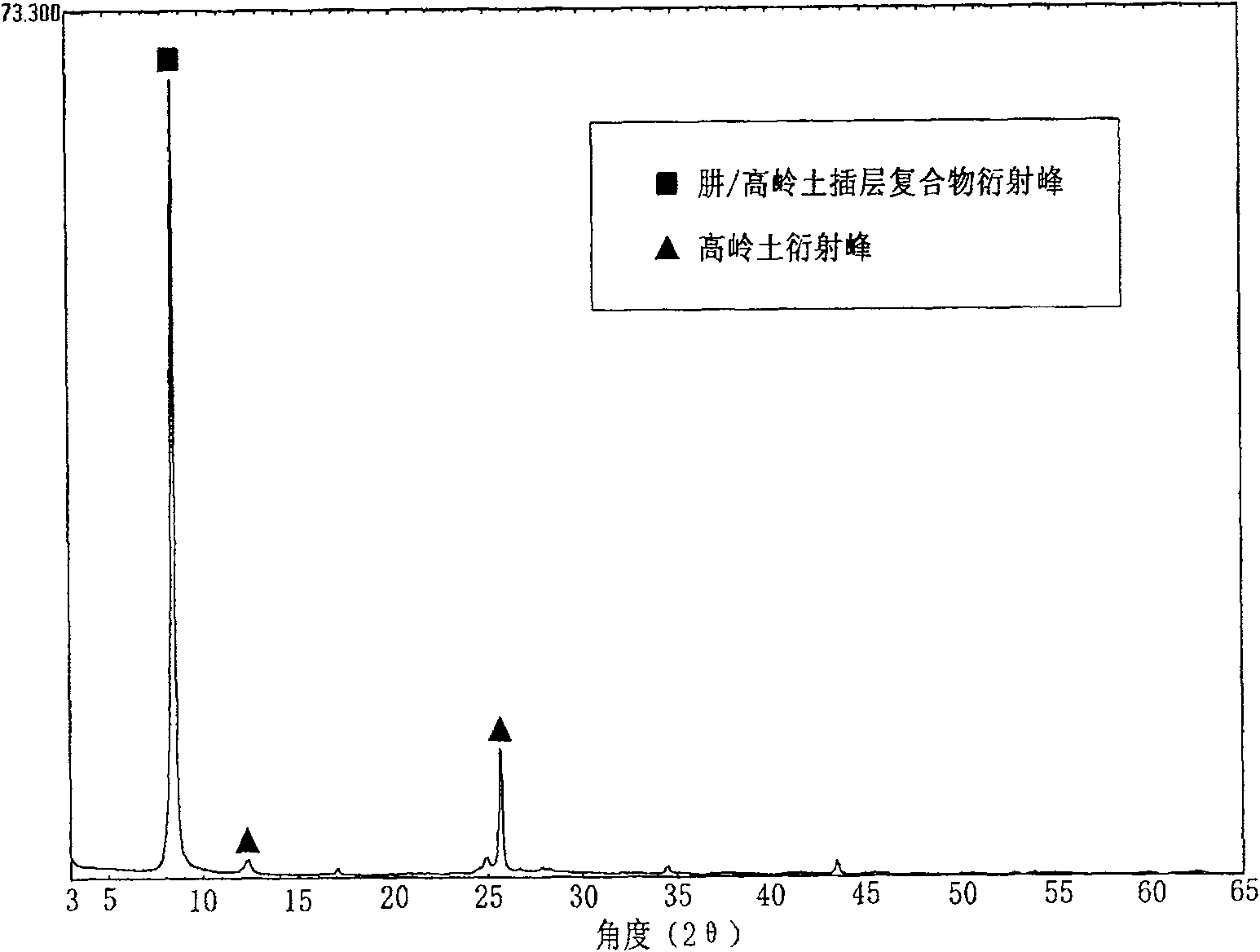

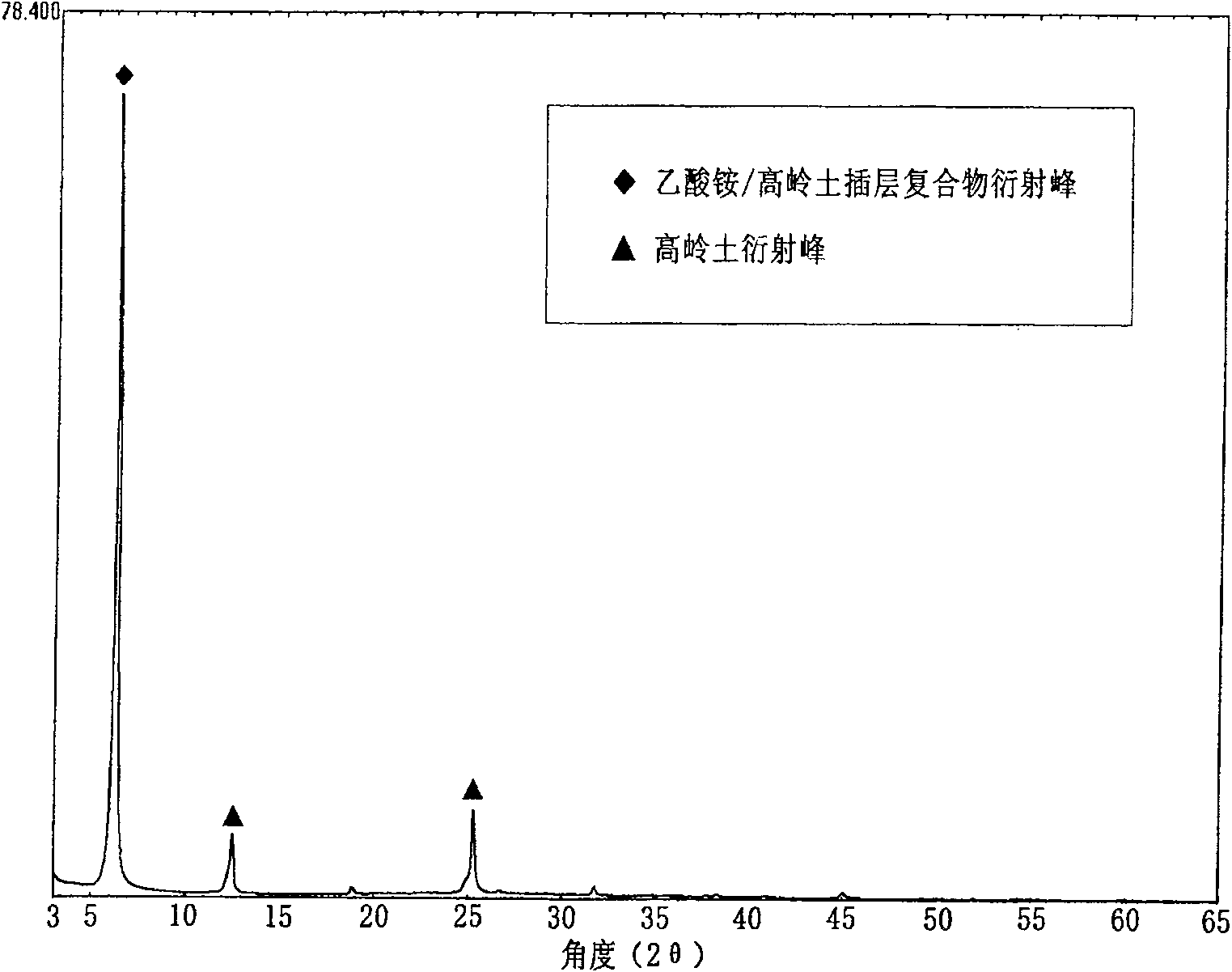

[0053] Take by weighing 20 grams of made ammonium acetate / kaolin intercalation complex, then weigh 1 gram of octadecylamine ( Figure 4 ); first melt octadecylamine at 75°C, quickly add it to the ammonium acetate / kaolin intercalation compound, stir with a glass rod in an oil bath at 70°C for 1 hour, then put it in an oven at 70°C for 12 hours; take it out and cool Finally, the cooling complex is obtained; the cooling complex is washed and filtered with a mixed solution of ethanol and water with a volume ratio of 1:1, and dried in an oven at 55°C for 12 hours to obtain the octadecylamine / kaolin intercalation complex ( Figure 5 ), by X-ray diffraction (XRD) Figure 5 It can be seen that after the stearylamine molecule enters the interlayer of the ammonium acetate / kaolin intercalation structure, the (001) interlayer distance expands from 1.40nm to 8.33nm, and the intercalation rate can reach 91.7%.

Embodiment 2

[0055] Weigh 20 grams of the prepared ammonium acetate / kaolin intercalation complex, and then weigh 2 grams of octadecylamine; first melt the octadecylamine at 75° C., and then quickly add it to the ammonium acetate / kaolin intercalation complex, Stir with a glass rod in an oil bath at 70°C for 1 hour, and then put it in an oven at 70°C for 12 hours; take it out and cool it down to obtain a cooling compound; use a mixed solution of ethanol and water with a volume ratio of 1:1 for the cooling compound Washing and suction filtration, put into 55 ℃ oven and dry, promptly obtain octadecylamine / kaolin intercalation complex ( Image 6 ), by X-ray diffraction (XRD) Image 6 It can be seen that after octadecylamine molecules enter the interlayers of the ammonium acetate / kaolin intercalation structure, the (001) interlayer spacing expands from 1.40 nm to 8.71 nm, and the intercalation rate can reach 84.7%.

Embodiment 3

[0057] Take by weighing 20 grams of the prepared ammonium acetate / kaolin intercalation complex, and then weigh 3 grams of octadecylamine; first melt the octadecylamine at 75° C., and then quickly add it to the ammonium acetate / kaolin intercalation complex, Stir with a glass rod in an oil bath at 70°C for 1 hour, and then put it in an oven at 70°C for 12 hours; take it out and cool it down to obtain a cooling compound; use a mixed solution of ethanol and water with a volume ratio of 1:1 for the cooling compound Washing and suction filtration, put into 55 ℃ oven and dry, promptly obtain octadecylamine / kaolin intercalation complex ( Figure 7 ), by X-ray diffraction (XRD) Figure 7 It can be seen that after octadecylamine molecules enter the interlayers of the ammonium acetate / kaolin intercalation structure, the (001) interlayer spacing expands from 1.40 nm to 9.59 nm, and the intercalation rate can reach 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com