Vehicle electric control mechanical speed-changer gear-selecting and shifting mechanism

A gear selection and mechanical technology, applied in the direction of mechanical equipment, transmission control, transmission parts, etc., can solve the problems of AMT transmission, such as large changes, long design and production cycle, low production inheritance, etc., to achieve easy popularization and Promotion and application, good inheritance and adaptability, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

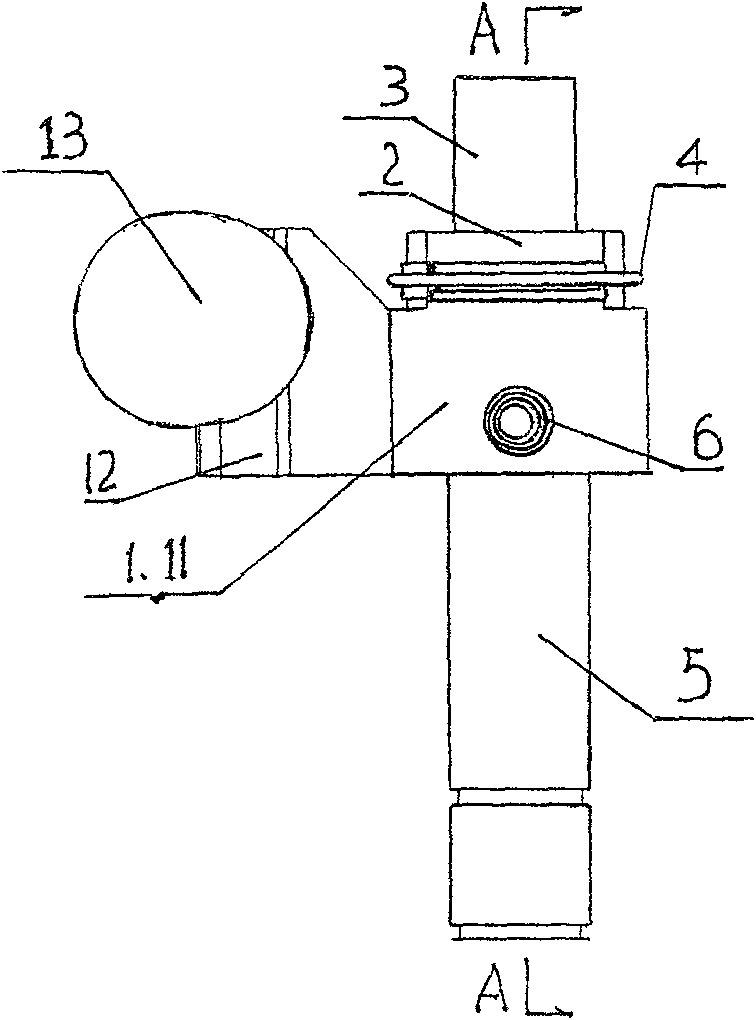

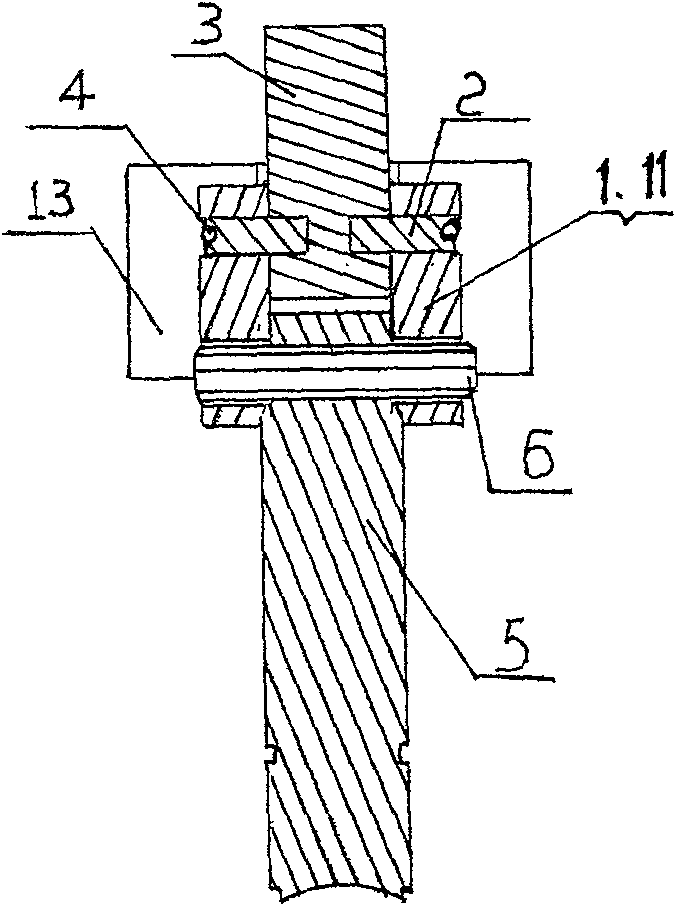

[0007] like figure 1 , figure 2 As shown, the gear shift mechanism is a conjoined piece 1 of a hollow cylinder 11 and a shift arm 12. The neck of the hollow cylinder is radially provided with a corresponding concave portion, and the concave portion is inserted into the center with a protruding portion. Positioning block 2, a groove is radially opened on the outer edge of the positioning block, and a locking spring 4 is arranged in the groove; the lower part of the hollow cylinder is radially provided with a pin hole, which is connected with the shift control shaft 5 inserted into the hollow cylinder. Corresponding shaft holes are connected and fixed by pins 6.

[0008] During installation, match the shift control shaft in the selector and shift mechanism with the shift shaft in the mechanical gearbox. The neck of the hollow cylinder 11 on the conjoined piece is matched with the gear selection piston rod 3 on the gear selection cylinder in the automatic gear selection and sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com