Shear transformation polymer network infrared liquid crystal light valve and manufacturing method thereof

A liquid crystal light valve and polymer technology, applied in optics, nonlinear optics, television, etc., can solve the problem that infrared scenes cannot satisfy the imaging seeker simulation test simulation, the manufacturing process of liquid crystal light valve is complex, and the reliability of devices is reduced, etc. problem, achieve the effect of increasing frame rate and dynamic range, small thickness dependence, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

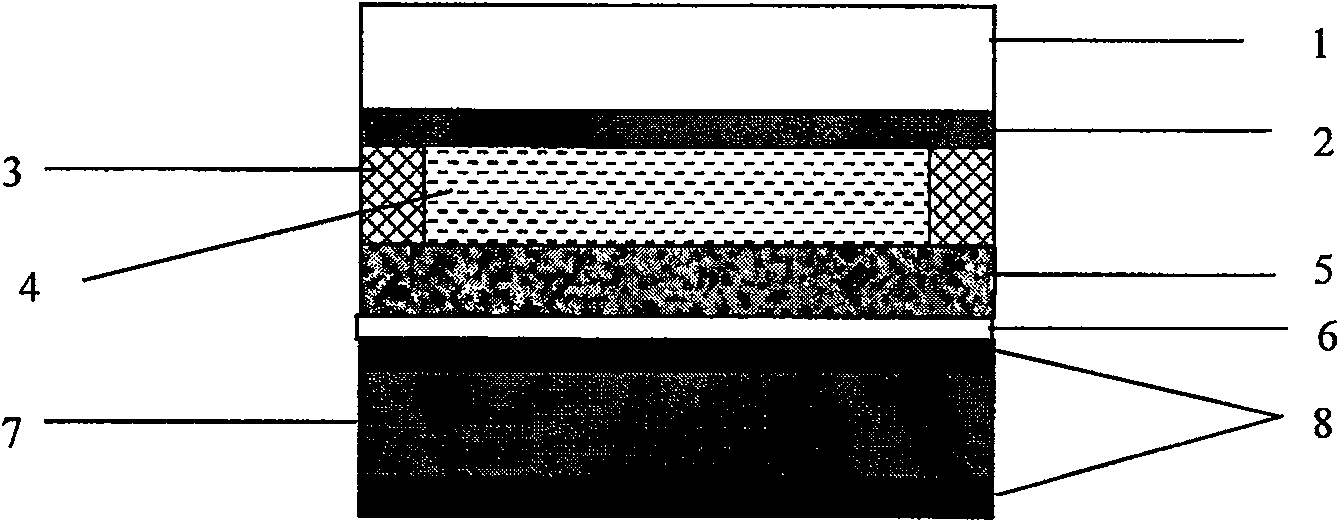

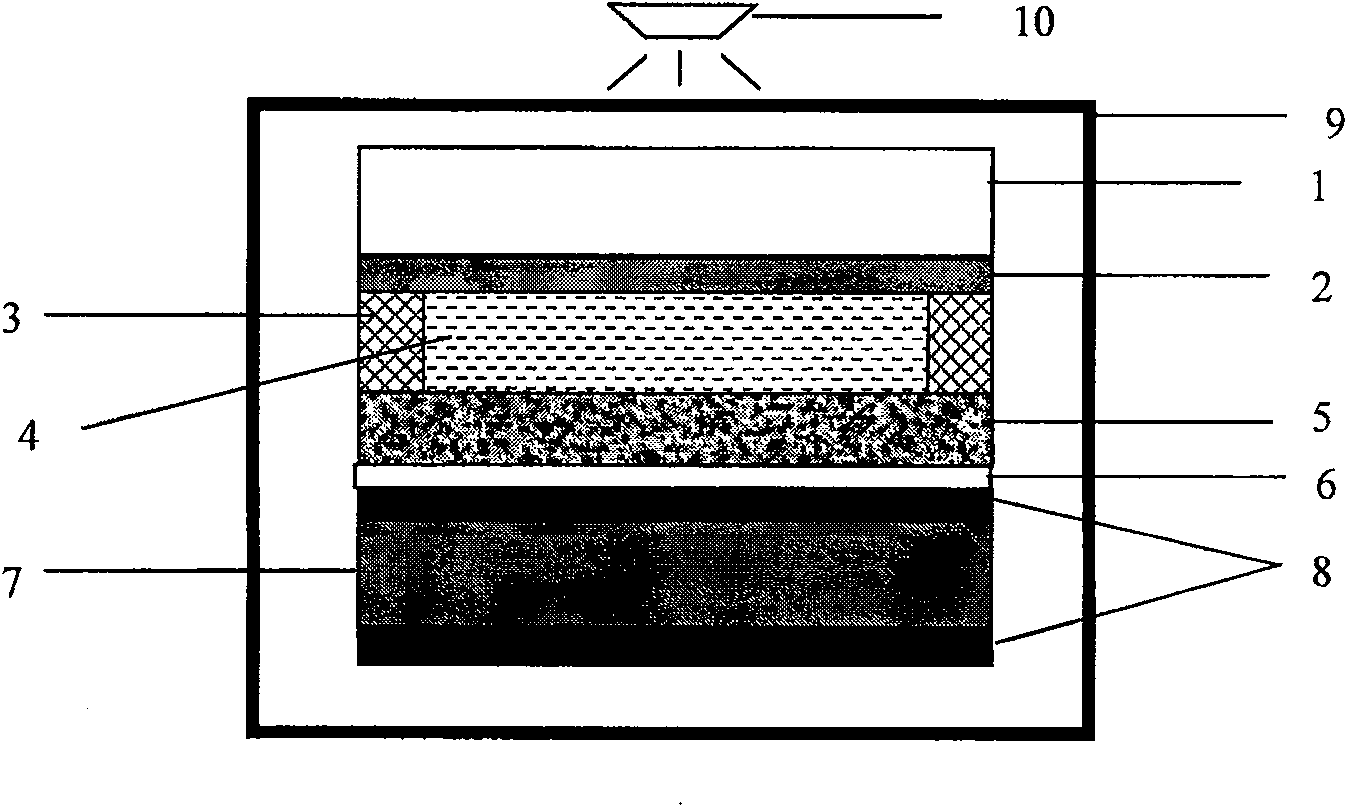

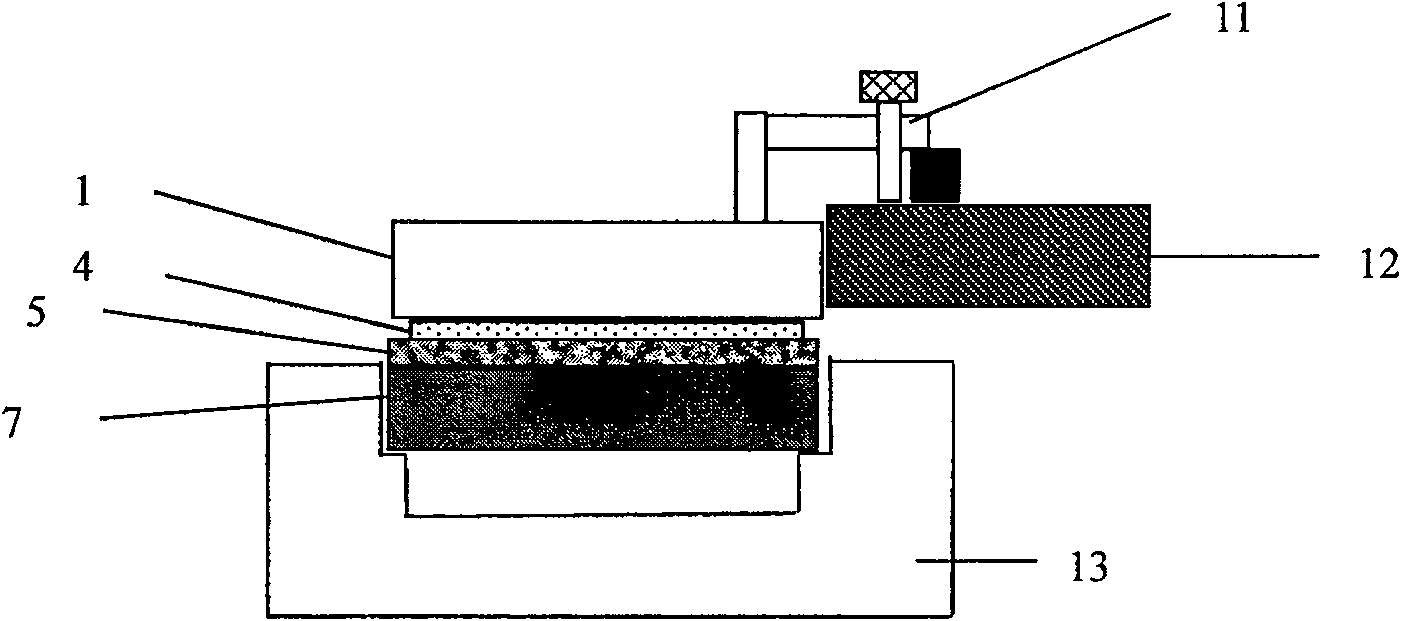

[0017] as figure 1 As shown, the shear polymer network infrared liquid crystal light valve provided by the preferred example of the present invention includes conductive glass comprising a glass substrate 1 and a transparent conductive layer 2, three insulating paper gaskets 3, a shear polymer network liquid crystal layer 4, Optical guide layer 5, germanium substrate 7. The glass substrate 1 is made of K9 glass with a diameter of 50 mm and a thickness of 10 mm. The thickness of the transparent conductive layer 2 is 20nm, and the material is indium tin oxide (ITO), whose average transmittance in the 350nm-380nm long-wave ultraviolet range is greater than 60%. The insulating paper gasket 3 has a thickness of 13 μm and a diameter of about 2 mm. The role of the insulating paper gasket 3 is to control the thickness of the shear polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com