Microwave filter has coaxial structure manufactured by metallized synthetic foam

A microwave filter, coaxial structure technology, applied in waveguide type devices, electrical components, circuits, etc., can solve the problems of complicated microwave filter, dielectric loss, expensive and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

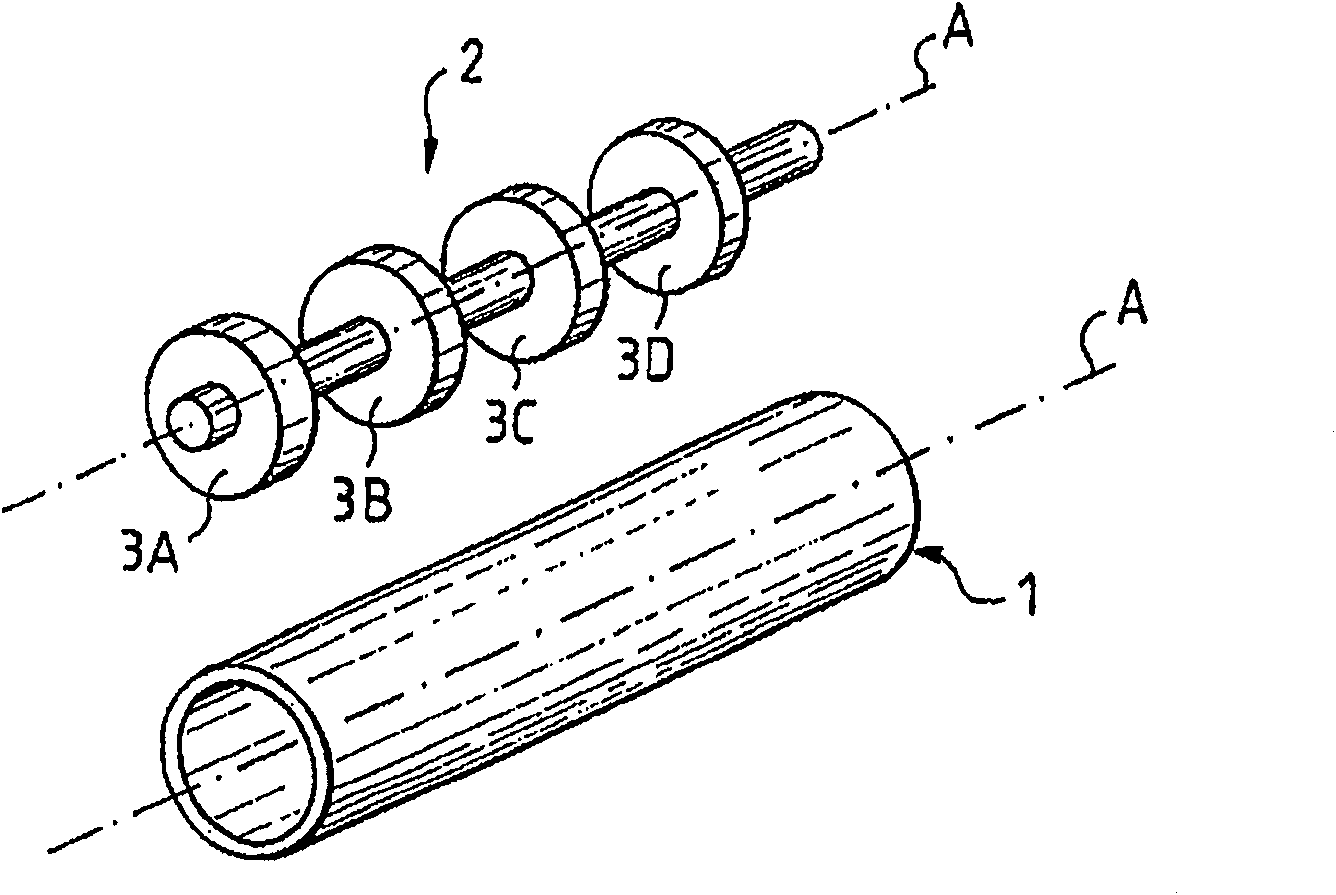

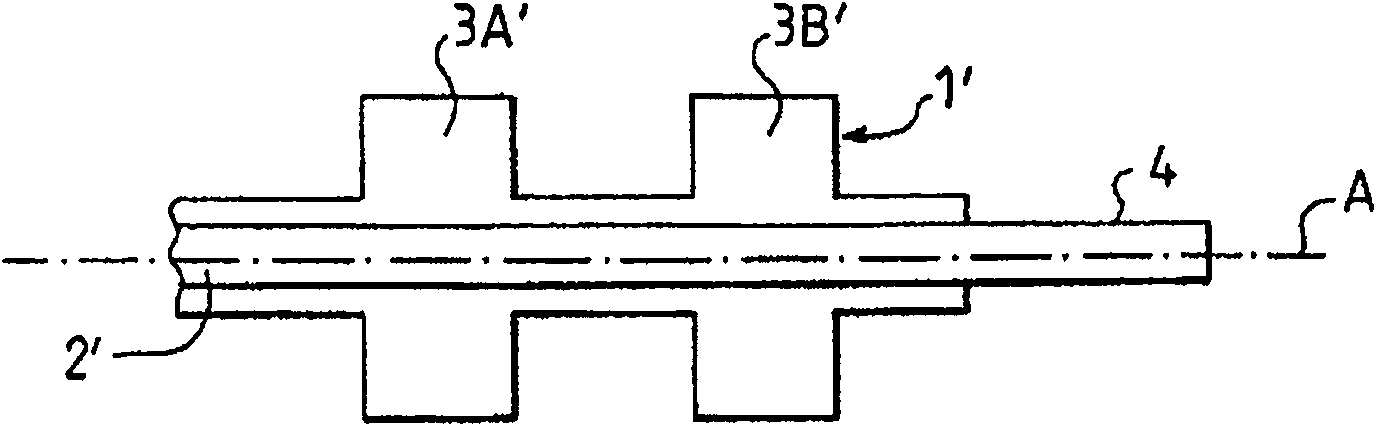

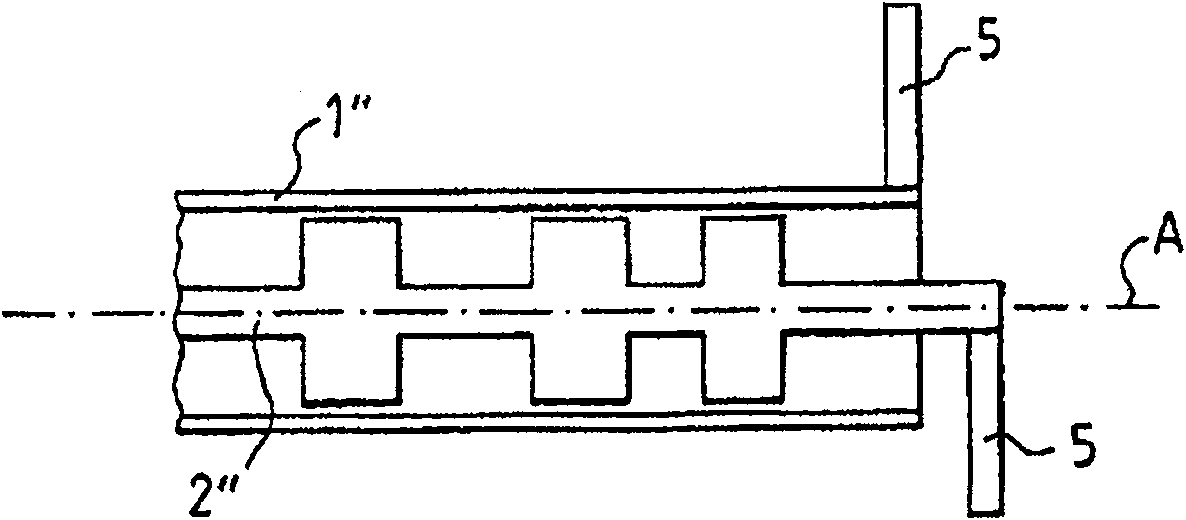

[0015] exist figure 1 A first example of a microwave filter with a coaxial structure according to the present invention is shown in an exploded perspective view.

[0016] For more clarity, in figure 1 The outer conductive tube 1 and the inner conductive rod 2 of the filter are shown separated from each other, but it must be understood that the rod 2 extends along the axial direction A in the outer tube 1 .

[0017] The inner rod 2 of the filter consists of a cylindrical rod made of synthetic foam, the outer surface of which follows a periodic function according to the axial direction. It is preferably formed as a continuous concentric crenellation 3A-3D to fulfill the transfer function of a filter, eg a low-pass filter by defining successive sections of the low and high characteristic impedance axes. The construction of the foam rod 2 takes place by thermoforming, in particular according to thermocompression molding techniques. The outer surface of the metallized foam rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com