Method and device for colouring metal index tag through electrophoresis

A sign, metal technology, applied in electrophoretic plating, electrolytic coatings, coatings, etc., can solve the problems of large waste in swimming tank coloring process, inability to guarantee coloring quality, large quantity of electrophoretic paint, etc., and save electrophoretic paint. , Reduce the amount of scrap, not easy to confuse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

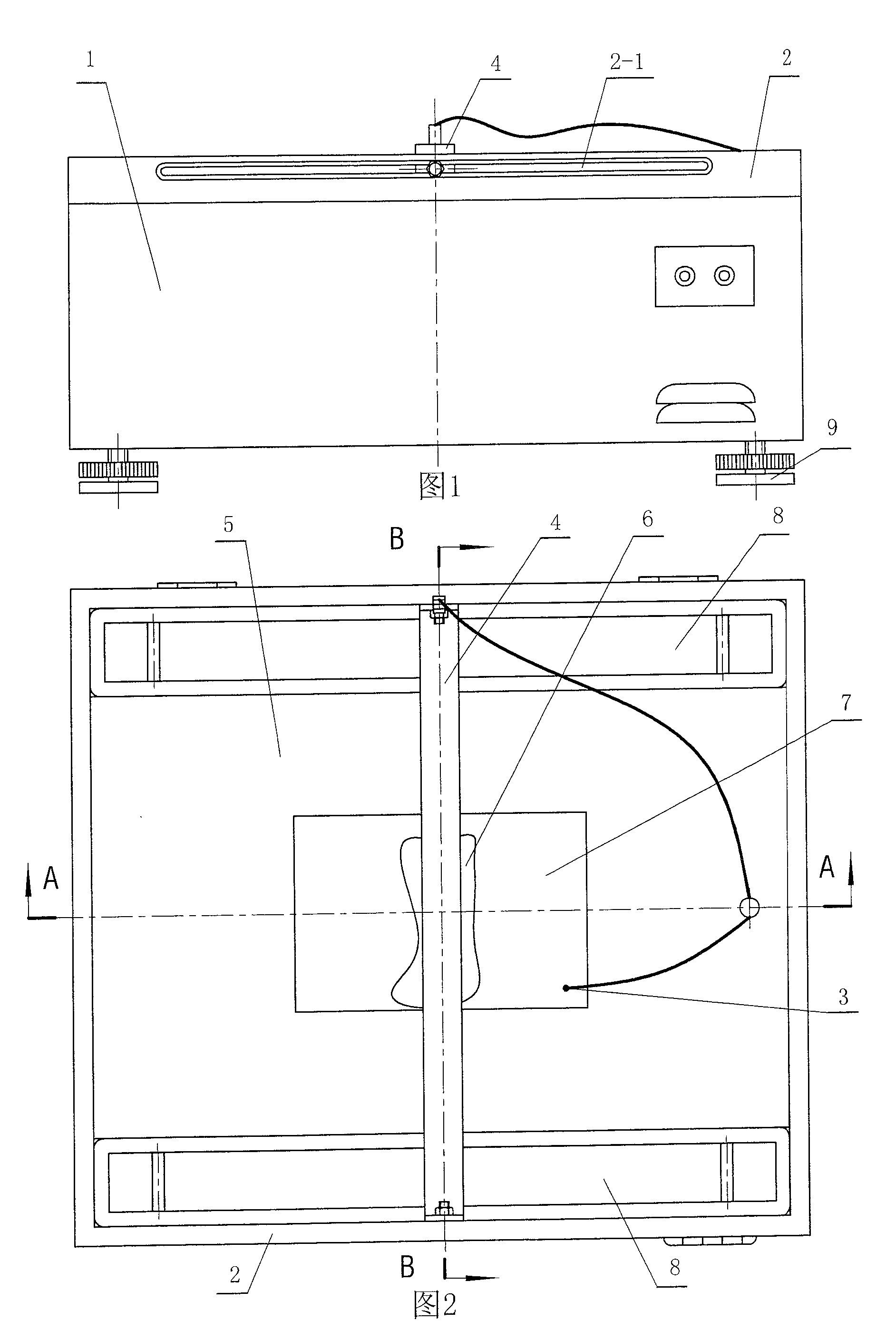

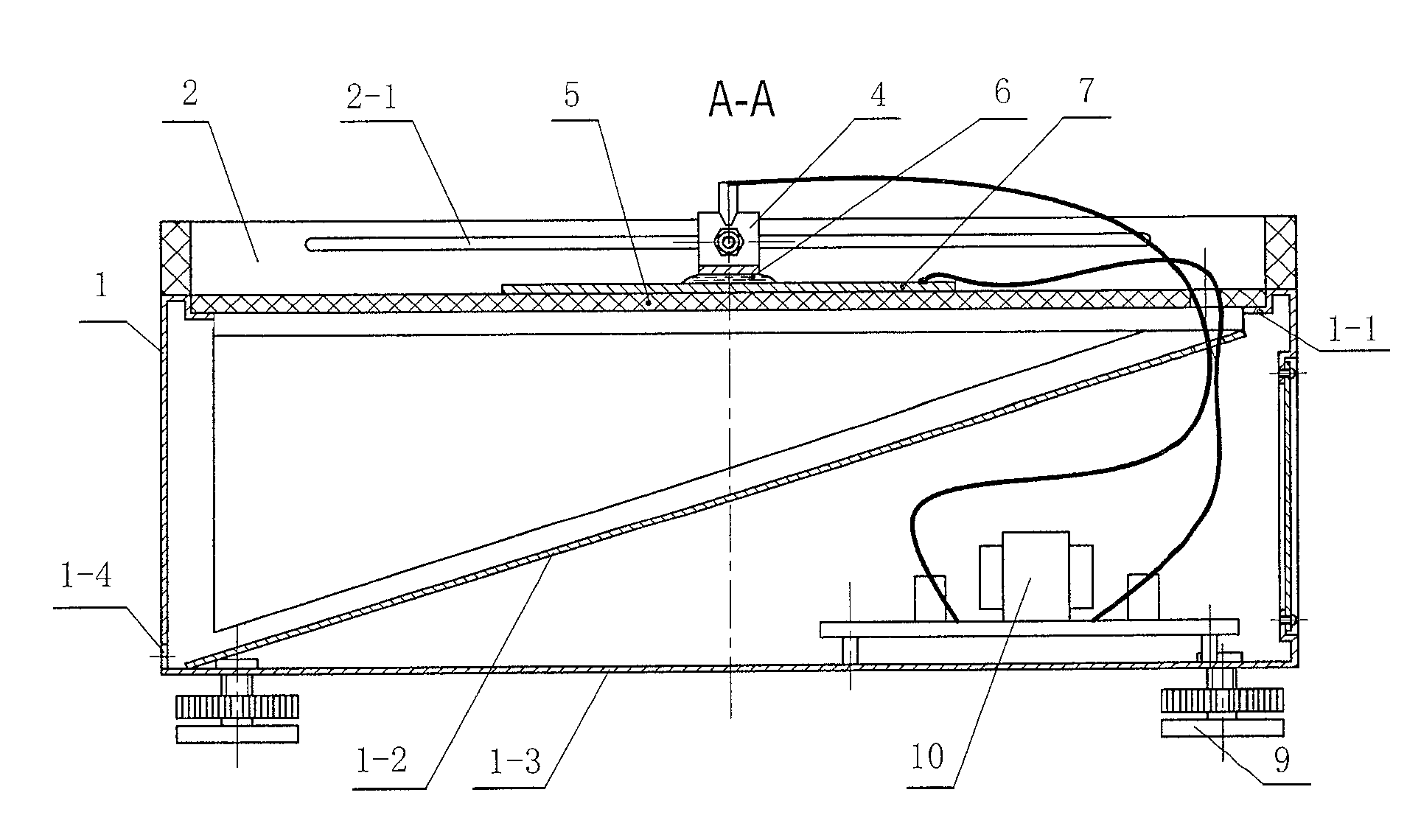

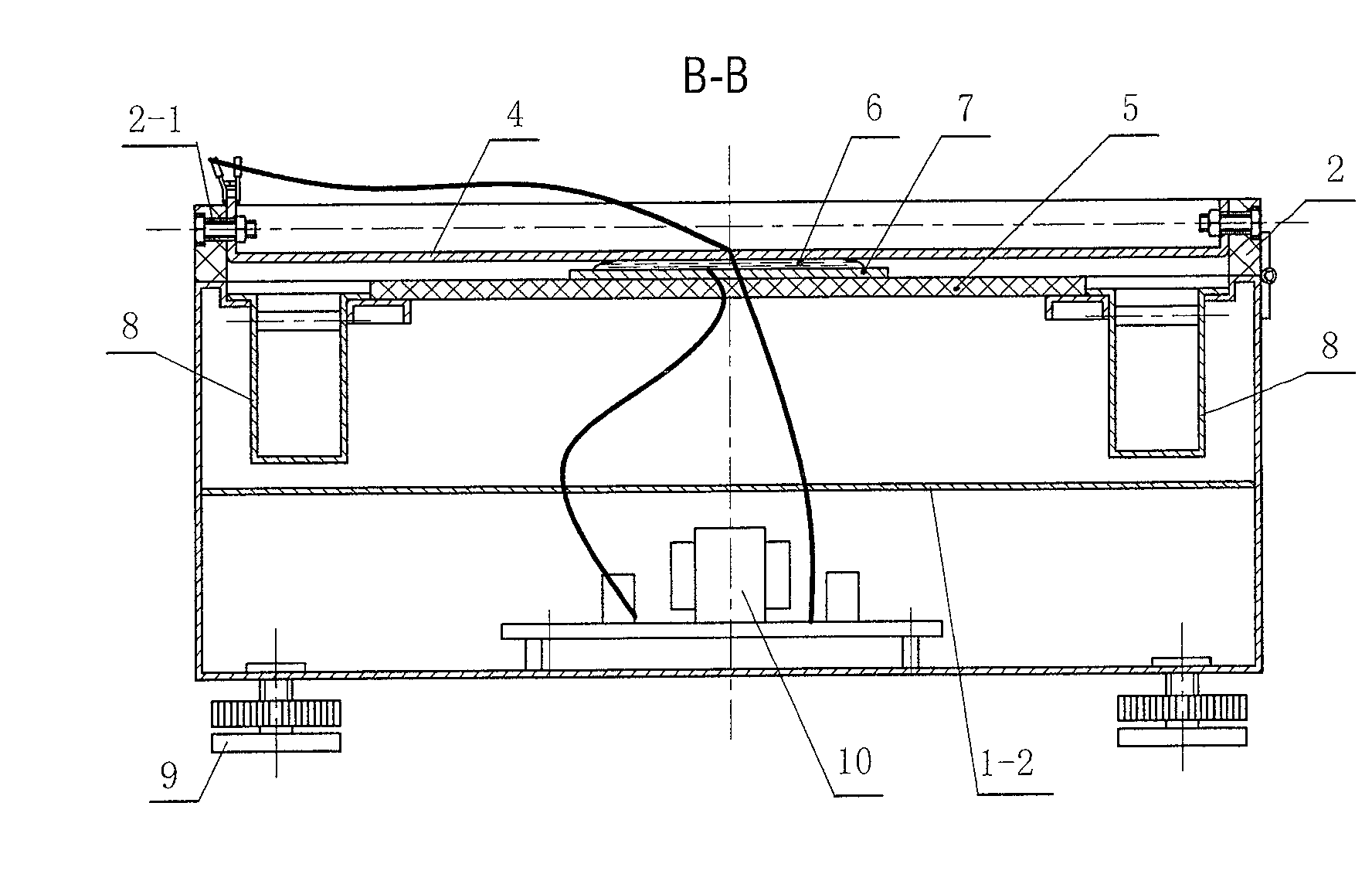

[0026] Such as figure 1 , 2 As shown, the first metal sign electrophoretic coloring method of the present invention is to electrically connect the first electrode 3 to the metal sign 7; arrange the metal sign 7 substantially horizontally with the surface to be colored upward; place the second electrode 4 Put it on the top of the metal sign 7; pour the electrophoretic paint 6 on the surface to be colored of the metal sign 7, make the second electrode 4 contact with the electrophoretic paint 6; then the two electrodes 3, 4 are energized for a period of time, and the process is completed Electrophoretic coloring process of metal signs. The distance between the second electrode 4 and the metal label 7 only needs to be able to keep the second electrode 4 in contact with the electrophoretic paint 6 . According to different signage materials or different electrophoretic paint materials, the electrification time of the two electrodes 3 and 4 can be several seconds to tens of minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com