Repeatable usable drawing rivet, and method of using same

A technology for pulling rivets and rivets, applied in the direction of rivets, etc., can solve the problems of easy loosening, poor firmness, and difficult disassembly of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

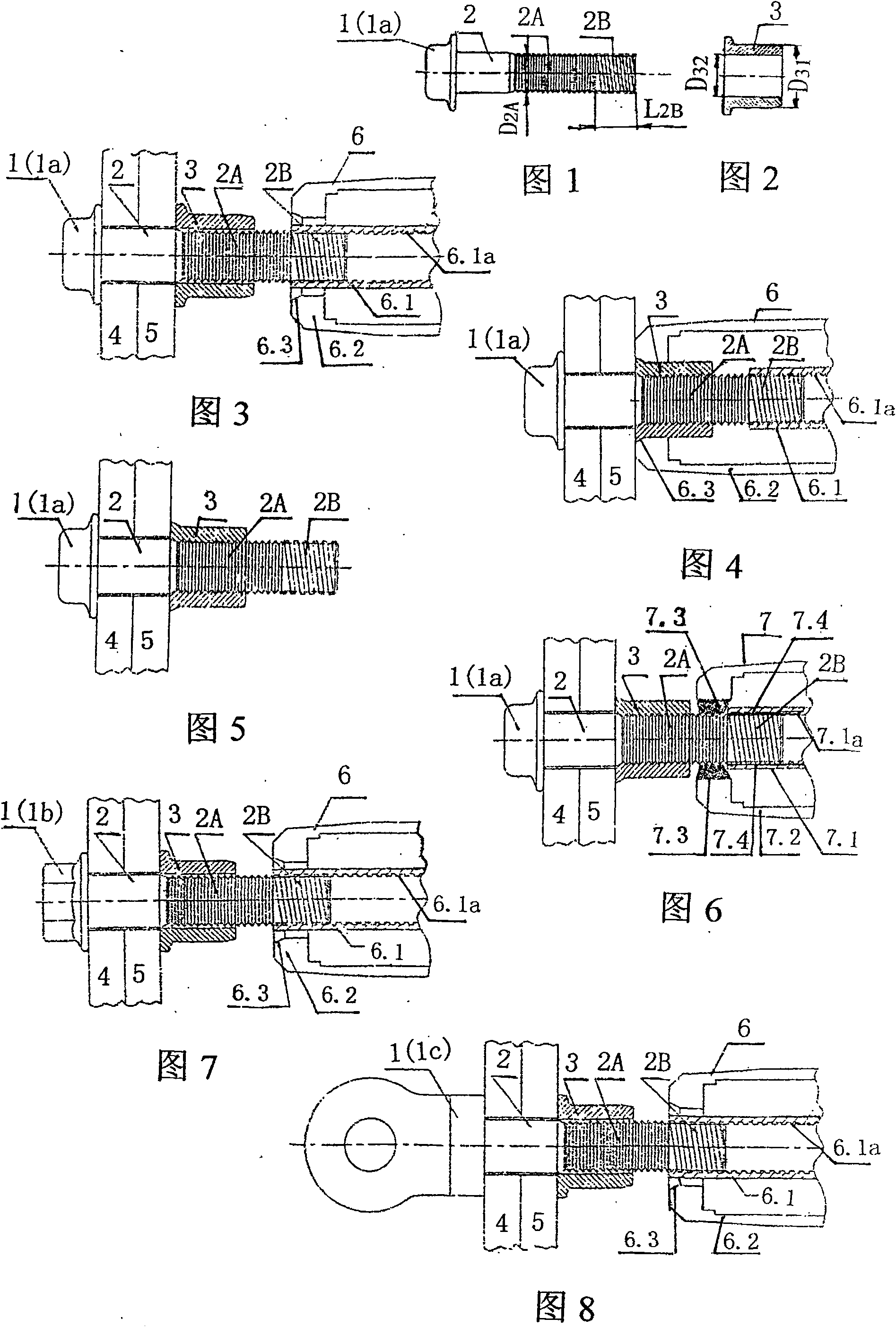

[0031] See figure 1 , figure 2 , The present embodiment 1 is a reusable blind rivet, which consists of a nail head 1, a nail shank 2 and a collar 3. The nail head 1 is a pan head 1a. The nail shank 2 is composed of a ring groove segment 2A at the front end and a ring groove segment 2A that is press-fitted with the collar 3 and an external thread segment 2B at the rear end. There is a short transition section between the two sections for processing.

[0032] In Example 1, a pull rivet can be used repeatedly to mark the diameter D=20mm, and the value of the outer diameter of the ring groove section is D 2A =19.2-20.2, length L of external thread segment 2B 2B =18.3-20.3. The outer diameter of the collar is D 31 =30.3-31.3, inner diameter value D 32 =19.3-20.3.

[0033] Riveting steps:

[0034] i. see image 3 , the nail rod 2 passes through the two objects 4 and 5 to be connected, the pan head 1a is close to the surface of the object 4, the collar 3 is set on the ring...

Embodiment 2

[0037] Example 2: see Figure 7 , The nail head 1 adopts a hexagonal flange 1b, which is used in the case where the rivet needs to be prevented from rotating during the riveting process. All the other structures and methods of use are exactly the same as in Example 1.

[0038]See figure 1 , figure 2 , this embodiment 2 can repeatedly use a pull rivet to mark the diameter D = 16mm, and the value of the outer diameter of the ring groove section is D 2A =15.1-16.1, length L of external thread section 2B 2B =17.2-19.2, the outer diameter of the collar is D 31 =25, 1-26.1, inner diameter value D 32 = 5.8-16.8.

Embodiment 3

[0039] Embodiment 3: see Figure 8 , Nail head 1 adopts eye ring 1c, which is used when other components need to be installed on the rivet. All the other structures and methods of use are exactly the same as in Example 1.

[0040] See figure 1 , figure 2 , this embodiment 3 can repeatedly use a pull rivet to mark the diameter D = 16mm, and the outer diameter of the ring groove section is D 2A =15.1-16.1, length L of external thread section 2B 2B =17.2-19.2, the outer diameter of the collar is D 31 =25.1-26.1, inner diameter value D 32 = 5.8-16.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com