Interference light detection device and method for calibrating same

A detection device, a technology of interference light, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as position and direction deviation, vibration, etc., to achieve the effect of convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

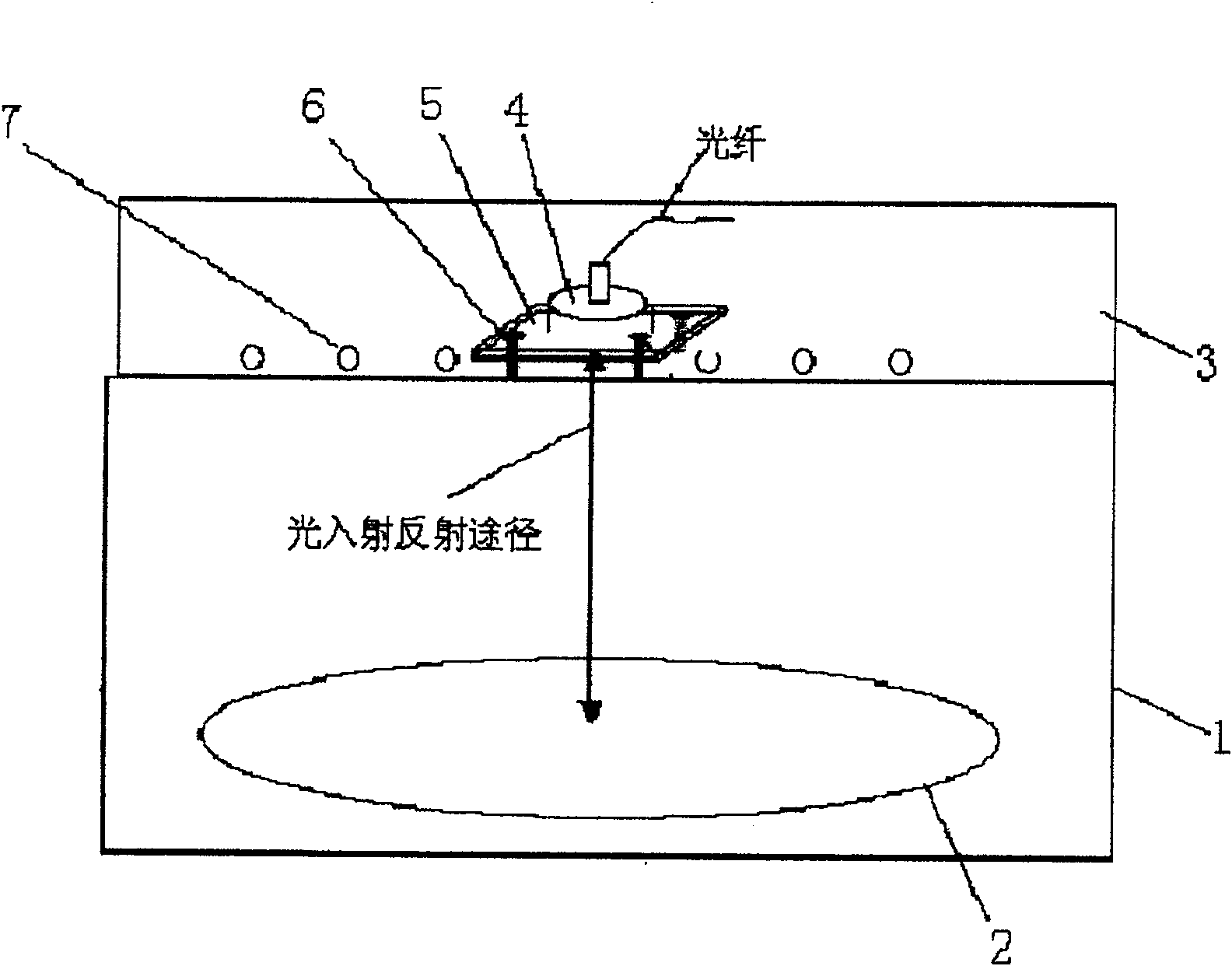

[0024] Interferometric light detection device of the present invention, such as figure 1 As shown, the shielding box 3 installed on the upper electrode 7 of the etching chamber 1 includes a probe 4 mounted on a support frame 5 , and an adjustment screw 6 is provided on the support frame 5 for calibrating the probe 4 . The probe 4 is connected with an external optical fiber, and is used for sending a light beam into the etching chamber 1 and receiving the returned light beam.

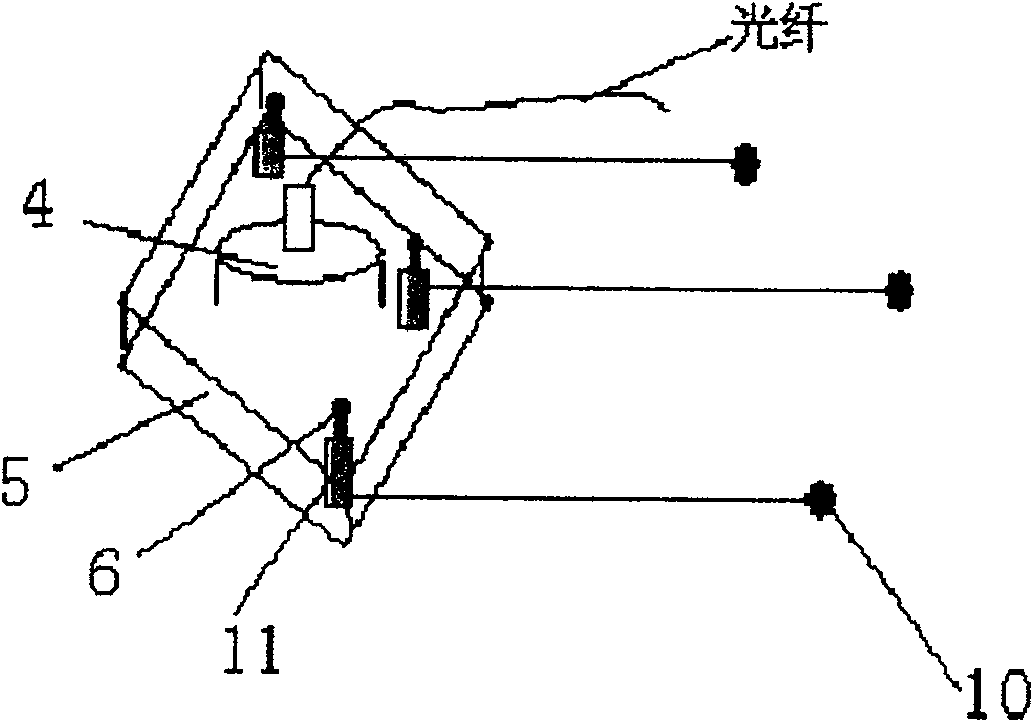

[0025] Its preferred specific implementation is as figure 2 As shown, an adjustment knob 10 is also included. The adjustment knob 10 is arranged outside the shielding box 3 and is connected with the adjustment screw 6 to adjust the adjustment screw 6 . In this way, each time the probe is adjusted, it is not necessary to open the upper electrode shielding box, and the adjustment knob can adjust the levelness of the probe support frame outside the upper electrode shielding box. Therefore, it can be achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com