Crystallizer molten steel level correction method

A calibration method and crystallizer technology, which is applied to liquid level indicators, instruments, machines/engines, etc., can solve the problems that the installation positions cannot be guaranteed to be completely consistent, and can not be guaranteed, so as to improve detection accuracy, improve accuracy, reduce The effect of small correction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

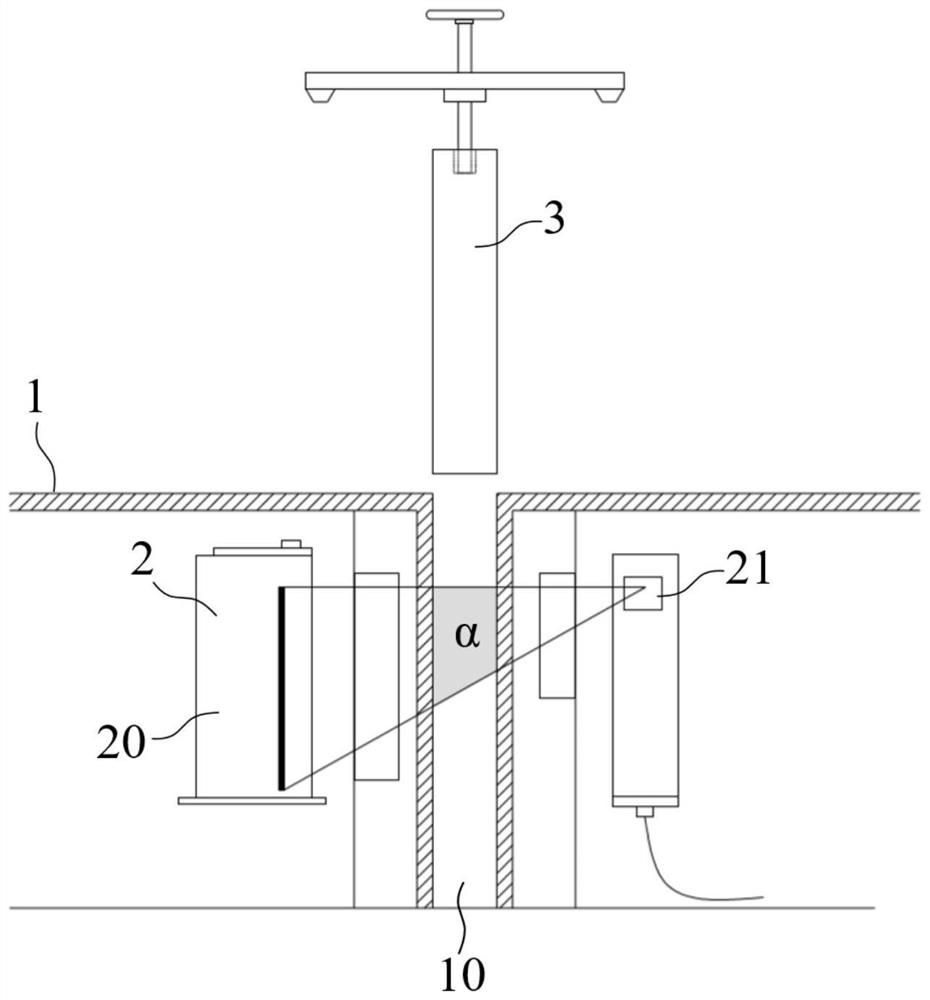

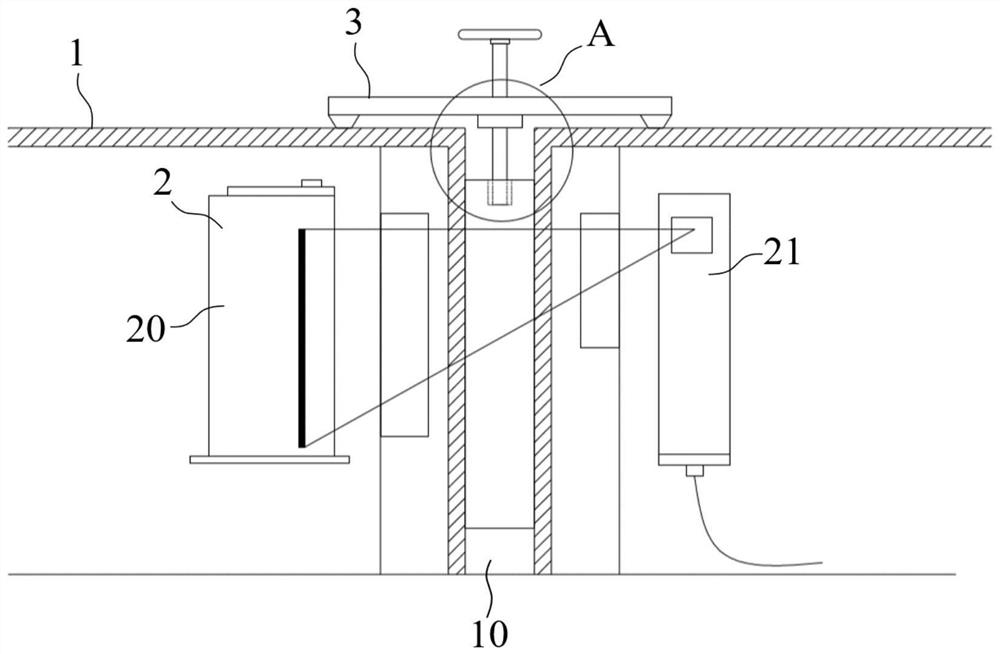

[0057] The mold steel liquid level correction method of the present embodiment adopts following correction device, and this device comprises:

[0058] Crystallizer 1, which is provided with crystallizer copper tube 10;

[0059] A liquid level detector 2, which includes a radiation source 20 arranged on one side of the mold copper tube 10 and a receiver 21 arranged on the other side of the mold copper tube 10;

[0060] Also includes a correction device 3, which includes:

[0061] Billet mold 30, which is placed in the crystallizer copper tube 10;

[0062] Support frame 31, which is placed directly above the crystallizer copper tube 10;

[0063] Screw mandrel 32, which runs through support frame 31 and is threadedly connected with support frame 31, and one end of screw mandrel 32 is rotationally connected with billet mold 30 top;

[0064] The handwheel 33 is fixedly connected with the other end of the screw mandrel 32 .

[0065] In this embodiment, the structure of the corre...

Embodiment 2

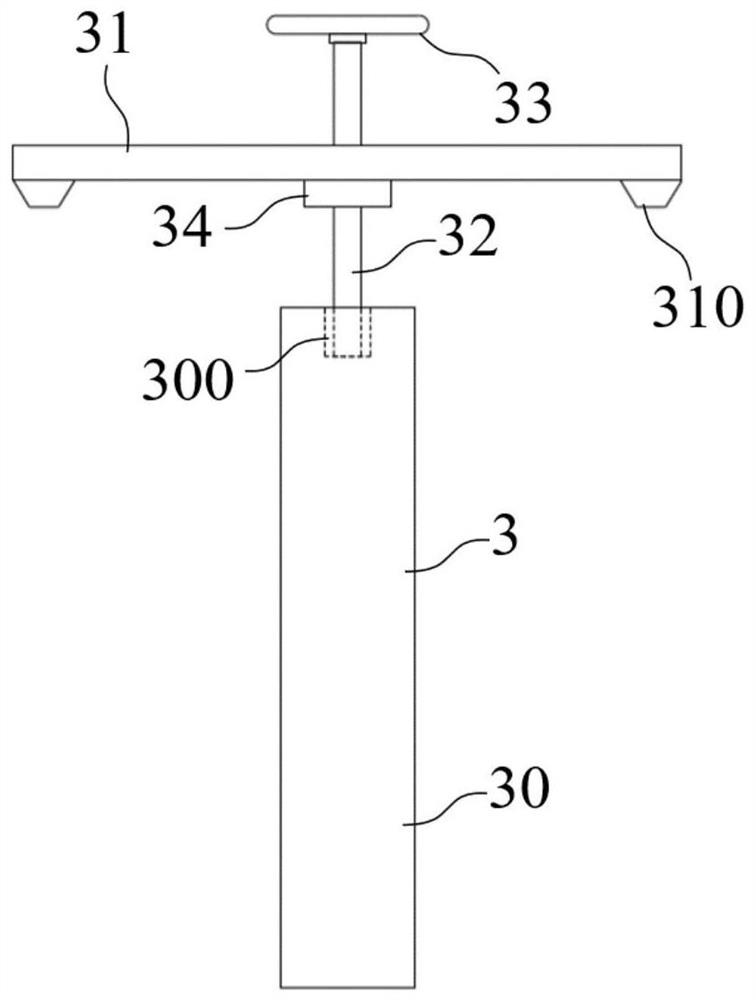

[0069] This embodiment is further improved on the basis of Embodiment 1. The correction device 3 also includes a support frame slider 34, which is fixedly connected to the bottom of the support frame 31, and the screw rod 32 runs through the support frame slider 34 and slides with the support frame. Block 34 threaded connection.

[0070] Such as figure 2 Shown, by arranging support frame slide block 34, increase the screw connection length between screw mandrel 32 and support frame 31 and support frame slide block 34, because billet mold 30 weight is bigger, set up support frame slide block 34, evenly share the support frame The downward load borne by the threads of 31 reduces the resistance when the screw mandrel 32 rotates, facilitates the adjustment of the height of the billet mold 30 by the rotation of the handwheel 33, and further facilitates the correction operation.

Embodiment 3

[0072] This embodiment is further improved on the basis of Embodiment 2. The support frame 31 further includes a buffer seat 310, which protrudes downwards and is formed on the bottom surface of the support frame 31. The buffer seat 310 is an elastic structure.

[0073] The steel billet mold 30 has a relatively high mass. When the support frame 31 is placed, the buffer seat 310 composed of an elastic structure can effectively buffer and prevent the deformation of the support frame 31 under impact force from affecting the accuracy of subsequent calibration operations.

[0074] Further, the buffer seat 310 can be an elastic structure with a buffer function such as a spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com