Method for testing and inhibiting electric precipitation back corona phenomenon

A technology of anti-corona and electric dust removal, applied in the direction of electrostatic separation, etc., to achieve the effect of suppressing the phenomenon of anti-corona, improving dust removal efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

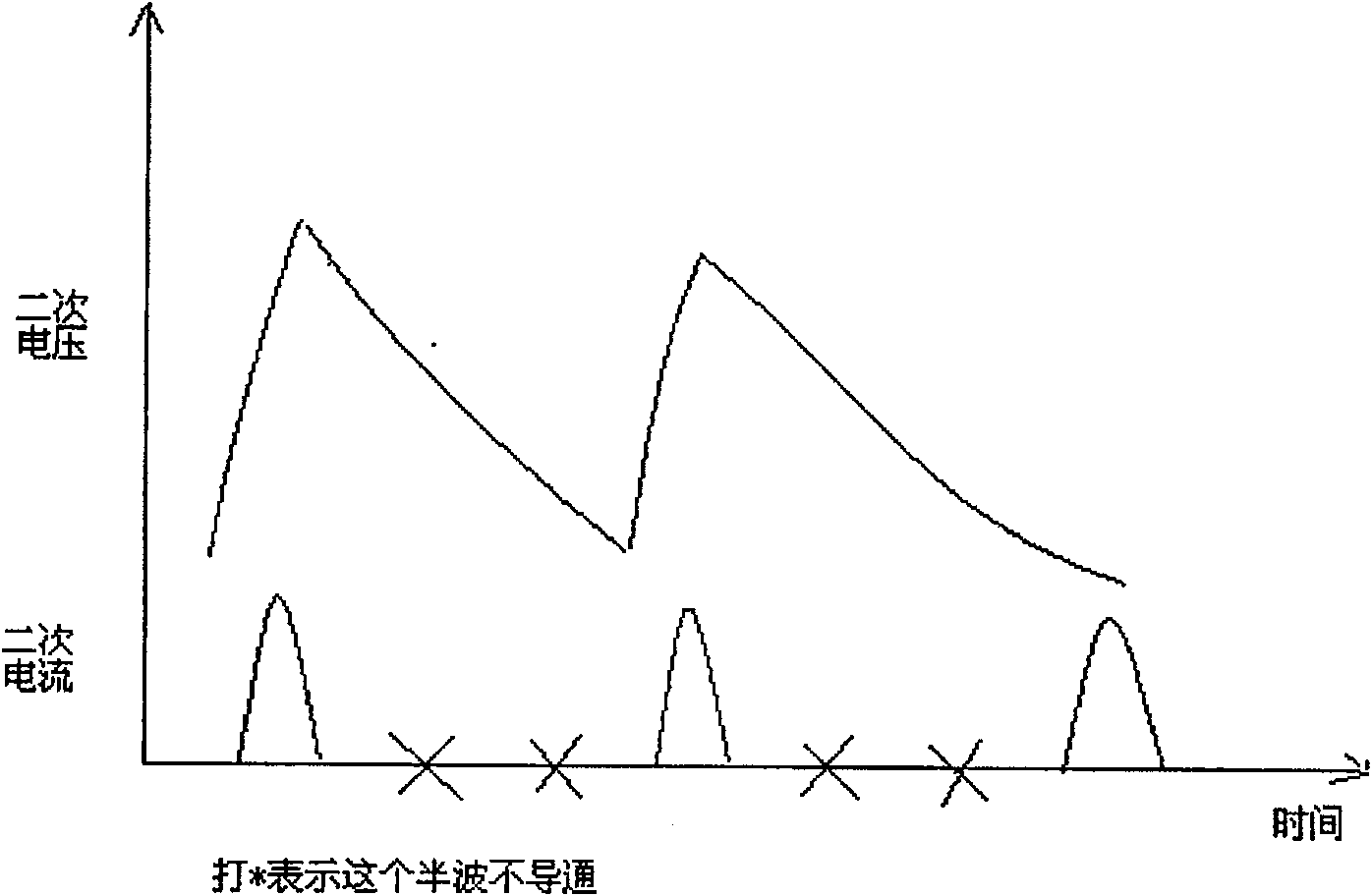

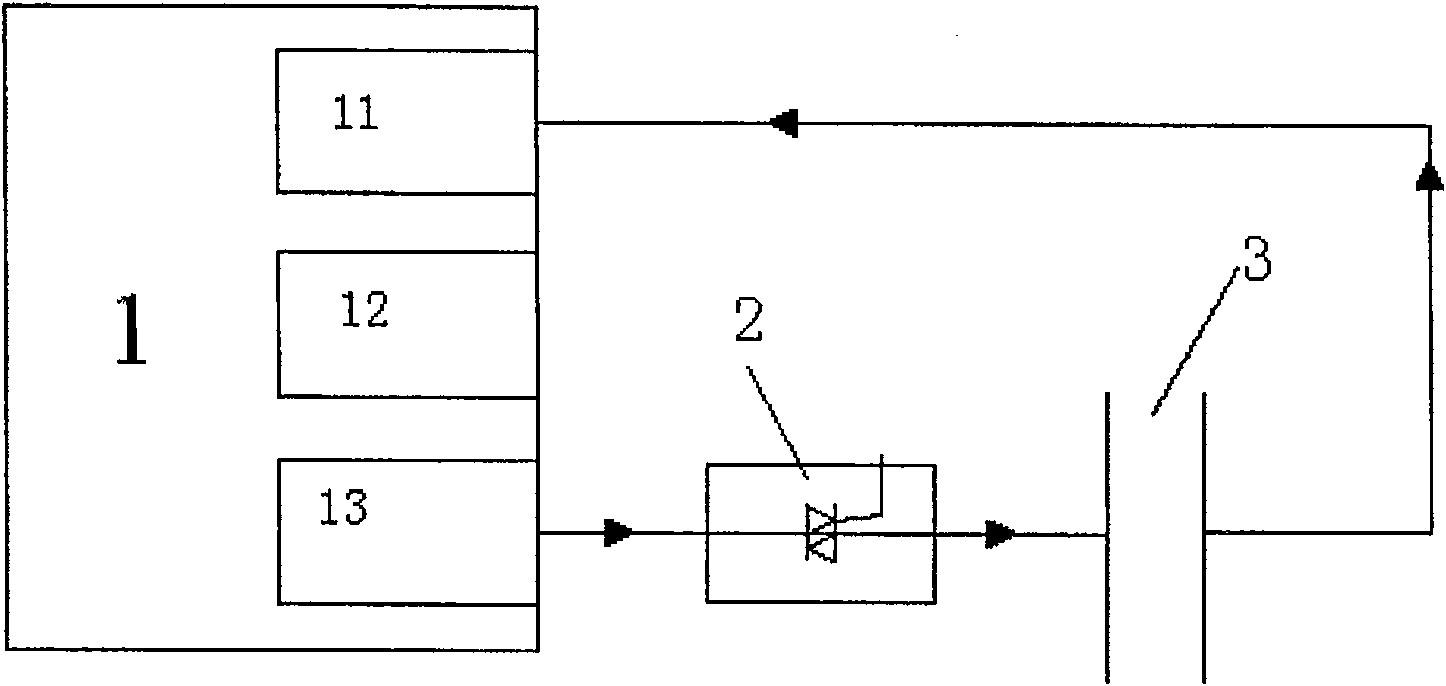

[0050] Such as figure 2 As shown, the structure of the electrostatic precipitator control system can be divided into three parts: the microprocessor 1, the execution unit 2 and the precipitator body 3; the microprocessor 1 includes a data acquisition unit 11, a control algorithm unit 12 and an output control unit 13 . One end of the execution unit 2 is connected to the output control unit 13 , and the other end is connected to the dust collector body 3 .

[0051] The data acquisition unit 11 is responsible for collecting the voltage and current data of the secondary side, and transmits the calculated average value and peak value of the voltage to the control algorithm unit 12 , and transmits the calculated average value of the current to the output control unit 13 . The output control unit 13 is responsible for adjusting the conduction angle of the thyristor according to the feedback current; the output of the execution unit 2 is boosted by the transformer, and then added to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap