Concrete distributing device

A distributor and concrete technology, which is applied in the processing of building materials, infrastructure engineering, construction, etc., can solve the problems of intermittent and discontinuous feeding, labor-intensive chutes, and easy occurrence of material blockage, so as to reduce usage and save energy. program, to avoid the effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

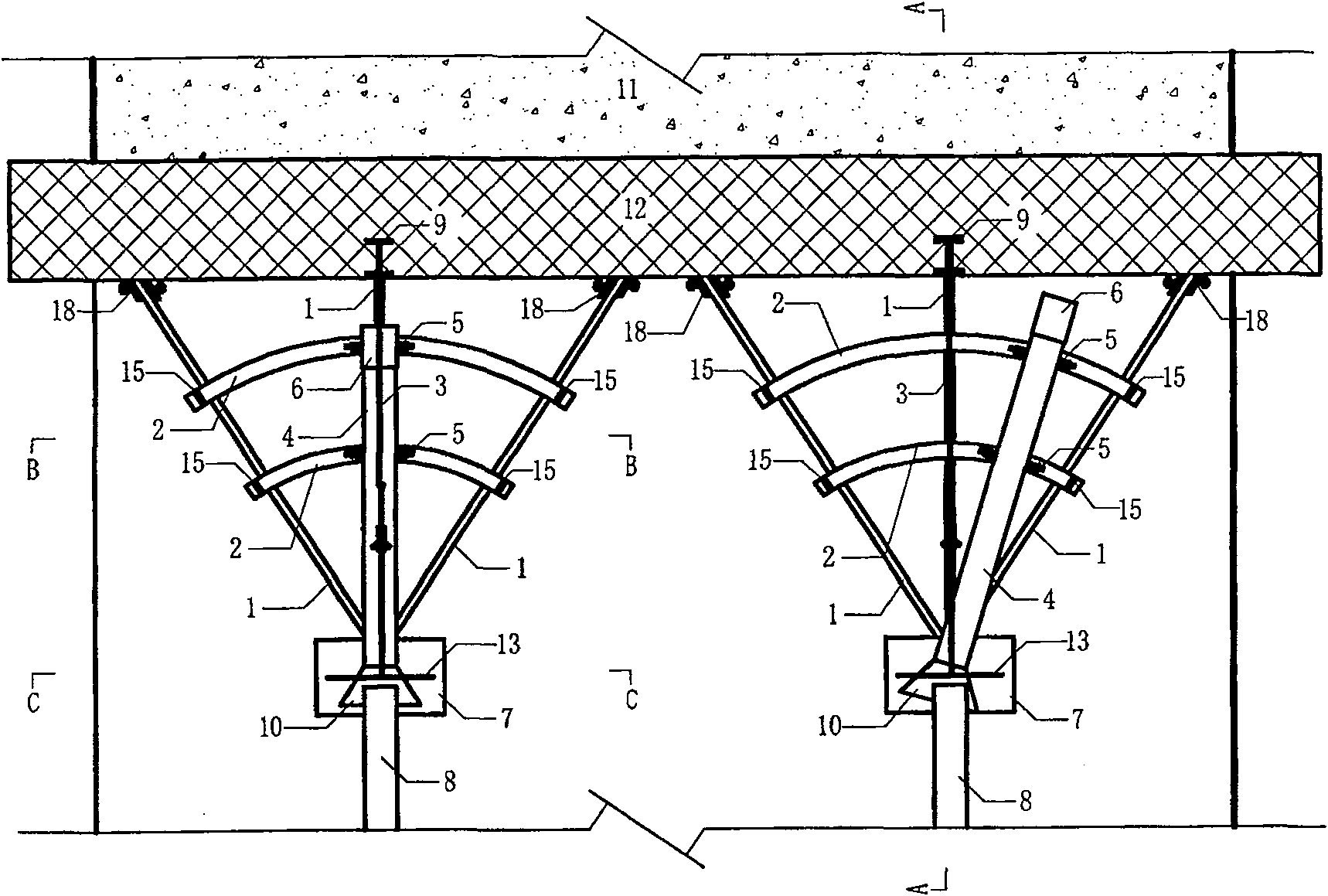

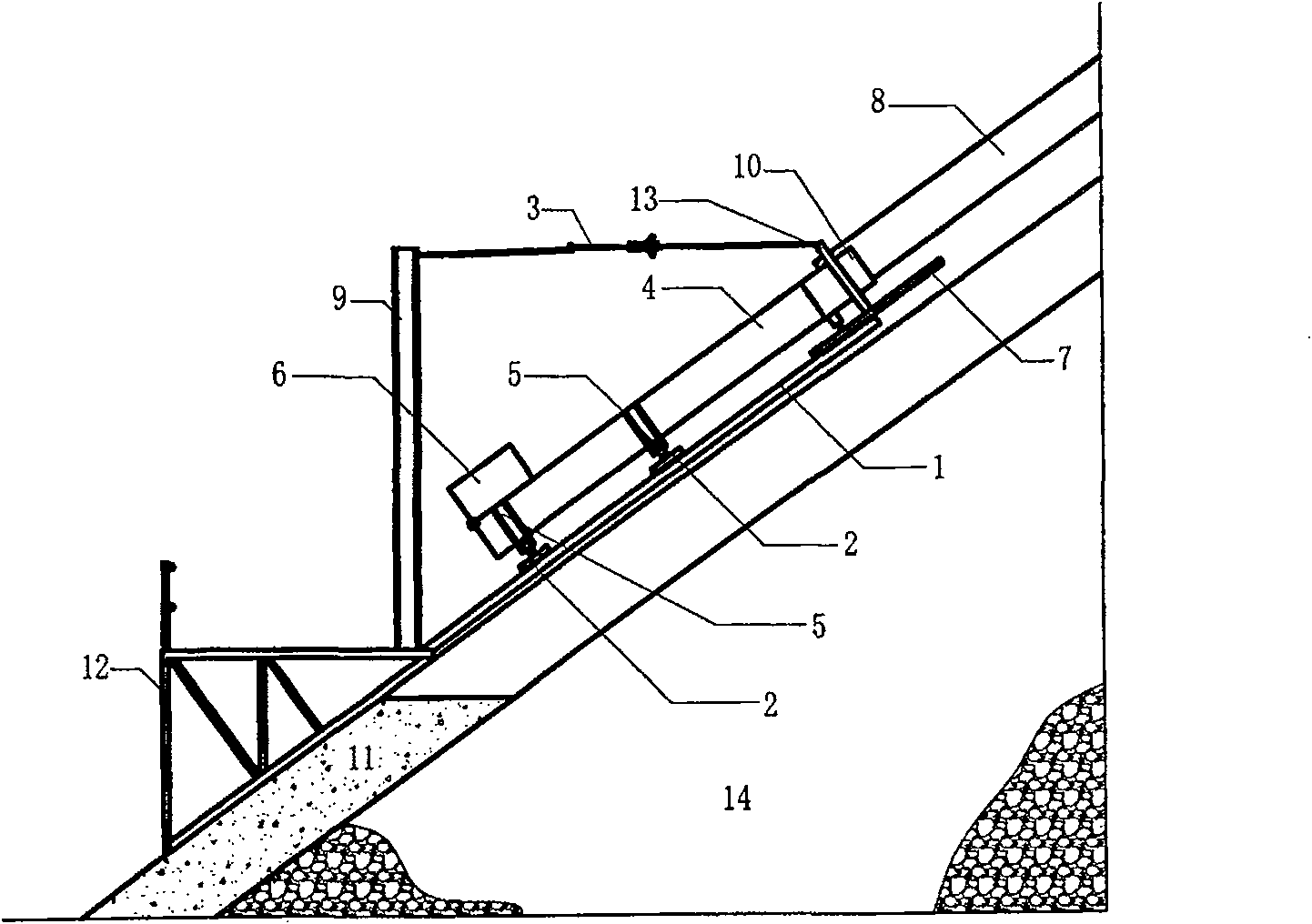

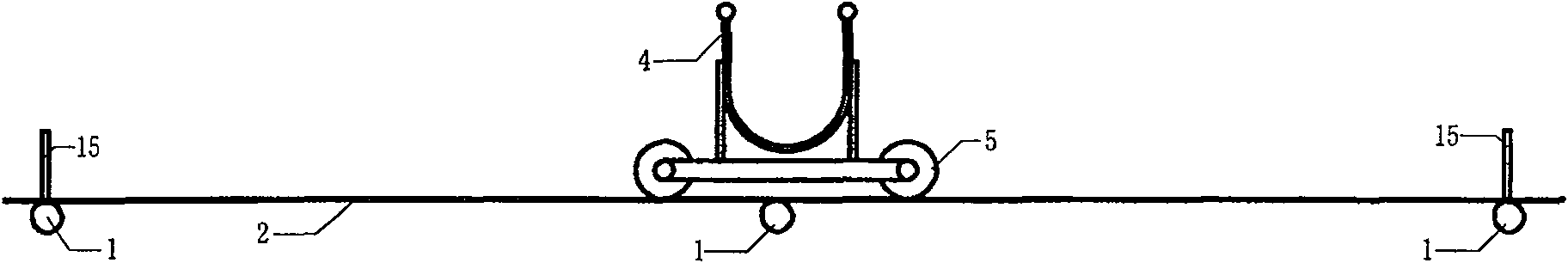

[0014] The present invention comprises chute, sliding form 12 and connecting steel plate 7, and connecting steel plate 7 is long 60cm, wide 50cm, thick 10mm, welds 3 φ 80 steel pipes on connecting steel plate 7 (length can be determined according to the width that actual distributor needs to control) as The support frame 1, the other end of the support frame diverges and is fixed on the front edge of the sliding form 12 through the connecting hinge 18, and the steel pipes on both sides form an equilateral triangle with the leading edge of the sliding form. Weld two concentric arc-shaped rails 2 with the intersection point of the support frame as the center of a circle on the end of the support frame 1 close to the sliding form, and the arc-shaped rails 2 are cross-connected with the support frame 1 to connect the support frame as a whole. The track is made of 20cm wide and 5mm thick steel plate. One track is set at a distance of not less than 50cm from the upper edge of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com