Glass slide way

A glass run, door glass technology, applied in mechanical equipment, transportation and packaging, engine components, etc., can solve the problems of deterioration of the installation state of the installation part and the decline of sealing performance, so as to improve the appearance quality, avoid the step difference, and improve the sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

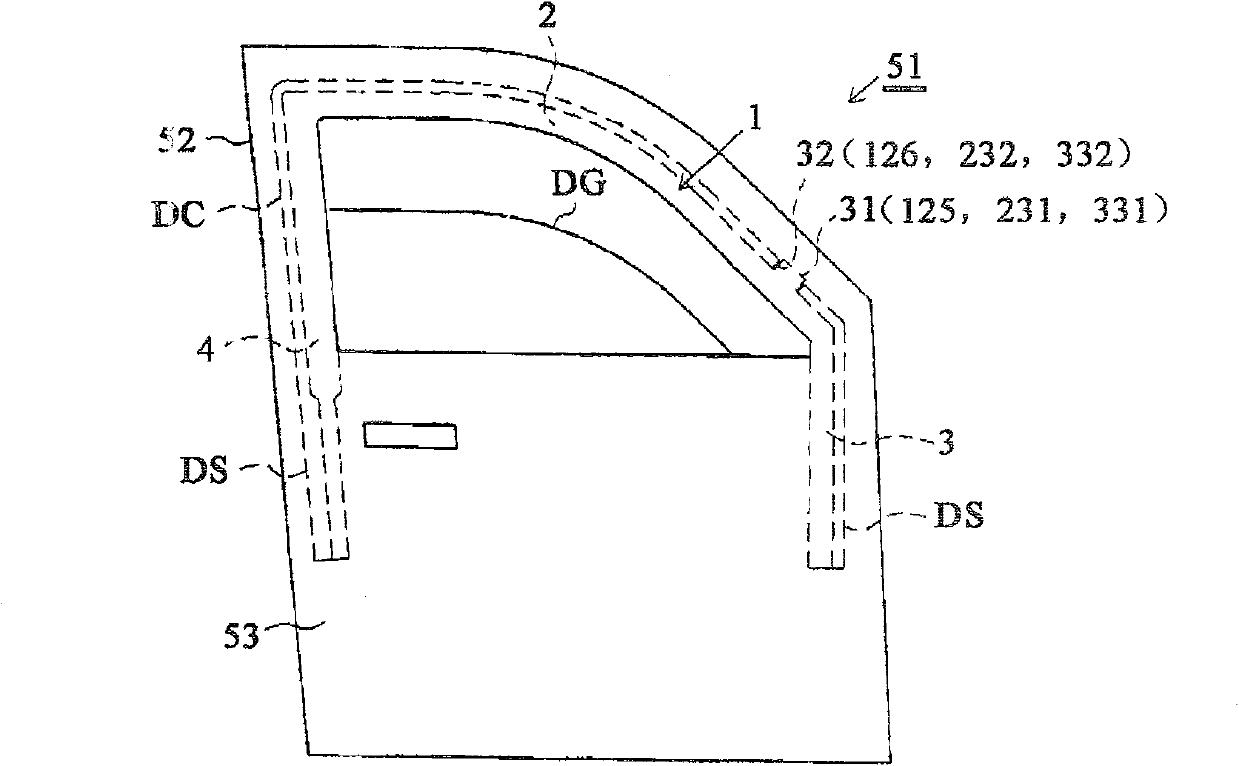

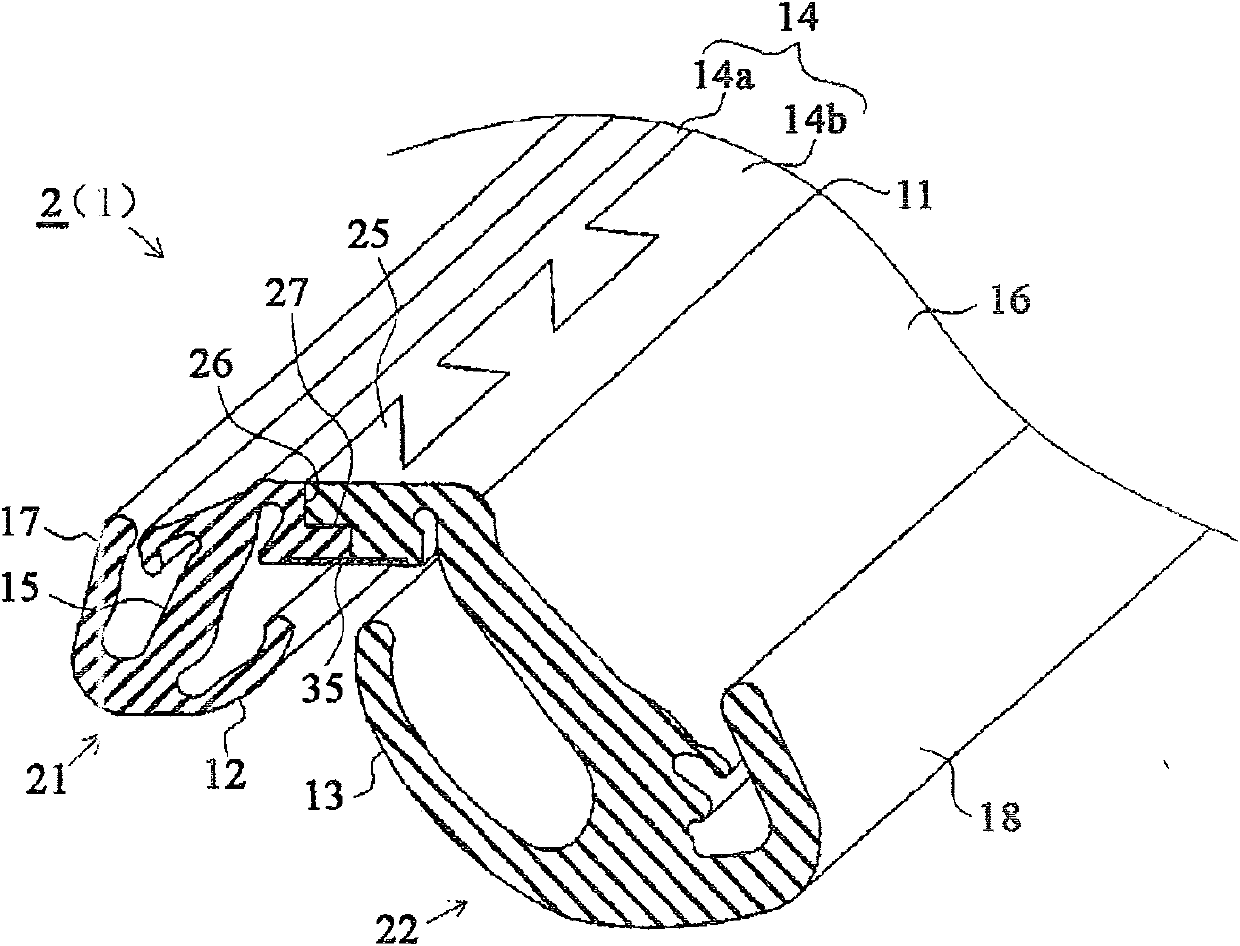

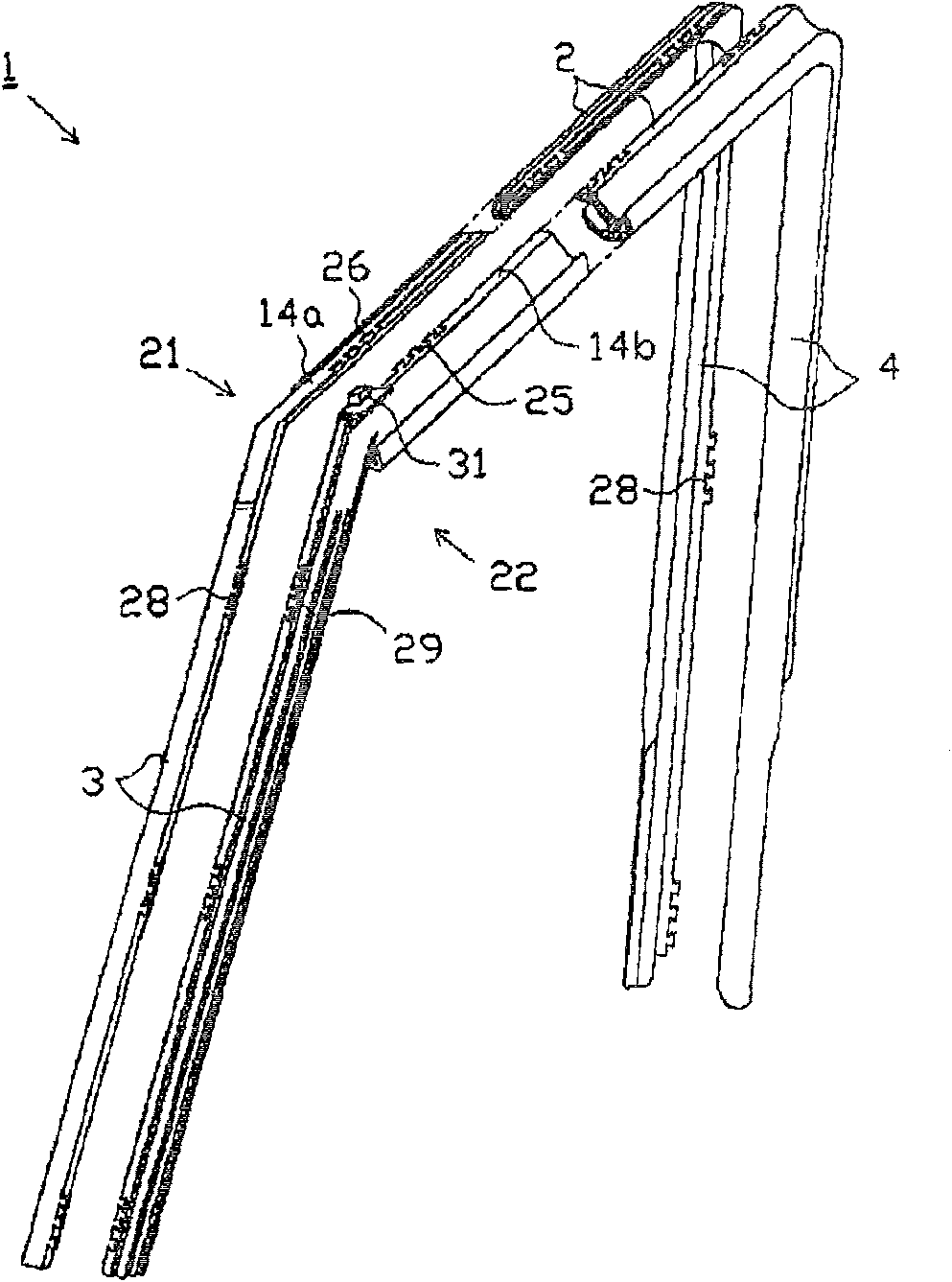

[0048] The first embodiment will be described below with reference to the drawings. figure 1 Schematic front view constructed for a car door. figure 2 It is a partial axonometric drawing of the upper side of the glass run. image 3 An exploded isometric view of the glass run.

[0049] Such as figure 1As shown, the door 51 of the vehicle (the front door in the figure) includes a glass runway 1, the glass runway is used to guide the lifting of the door glass DG, and when the door glass DG is raised to close the window, the door glass DG is controlled. The gap between the perimeter and the door frame 52 provides a seal. More specifically, the glass run channel 1 includes an upper side portion 2, a front vertical side portion 3 and a rear vertical side portion 4, the upper side portion 2 constituting a portion corresponding to the upper edge portion of the door glass DG, and the front vertical side portion 3 constitutes a portion extending downward from the front end portion ...

no. 2 example

[0088] A second embodiment will be described below with reference to the drawings. Figure 10 A sectional view showing the upper side of the glass run. Figure 11 It is a cross-sectional view showing the rear vertical side of the glass run channel in a disassembled state. Figure 12 An exploded isometric view of the glass run.

[0089] According to the second embodiment, as Figure 10 As shown, the upper side 2 includes a main body portion 111 and an outer sealing lip 112 and an inner sealing lip 113 . The main body portion 111 includes a bottom 114 fitted to the channel portion DC and an exterior side wall portion 115 and an interior side wall portion 116 extending from the bottom portion 114, and constitutes a substantially U-shaped cross section as a whole. The exterior seal lip 112 extends approximately from the distal end of the exterior wall portion 115 toward the inner periphery of the body portion 111 , and the interior lip seal 113 extends approximately from the di...

no. 3 example

[0122] A third embodiment will be described below with reference to the drawings. Figure 20 It is a cross-sectional view showing the state where the glass run channel is attached to the window frame part. Figure 21 A cross-sectional view of the glass run channel in an exploded state.

[0123] Such as Figure 20 , Figure 21 As shown, the upper side portion 2 includes: a main body portion 211 , an outer sealing lip 212 and an inner sealing lip 213 . The main body portion 211 includes a bottom portion 214 fitted to the channel portion DC, and an outer side wall portion 215 and an inner side wall portion 216 extending from the bottom portion 214 so as to constitute a substantially U-shaped cross section as a whole. The exterior seal lip 212 extends toward the inner peripheral side of the body portion 211 from the tip of the exterior wall portion 215 , and the interior lip seal 213 extends toward the inner periphery of the body portion 211 from the tip of the interior wall po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com