Cooking Oil Removal Panel Construct

A structure and panel technology, applied in the direction of oil fume removal, application, household stoves, etc., can solve the problems of difficult panel separation, inconvenient handling and cleaning, etc., and achieve the effects of improved degreasing effect, easy handling, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

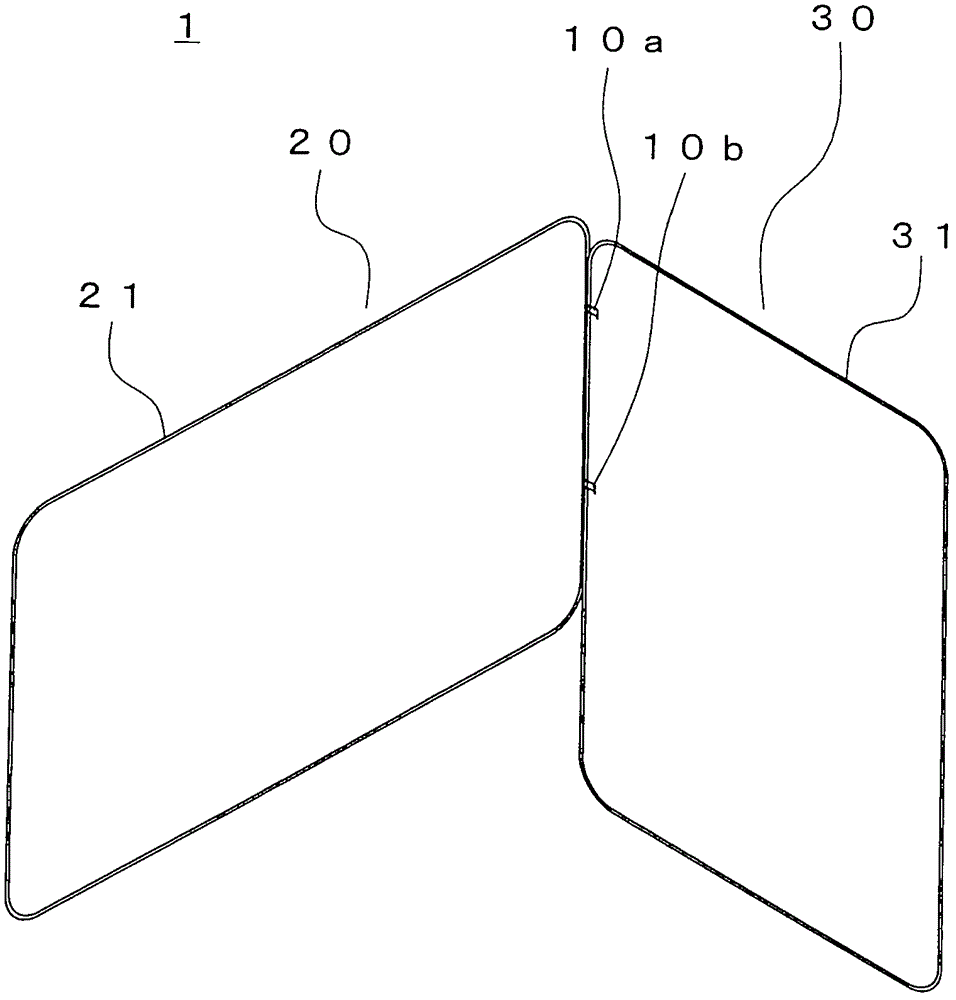

[0044] figure 1 It is a perspective view of the cooking oil removal panel structure of 1st Embodiment of this invention.

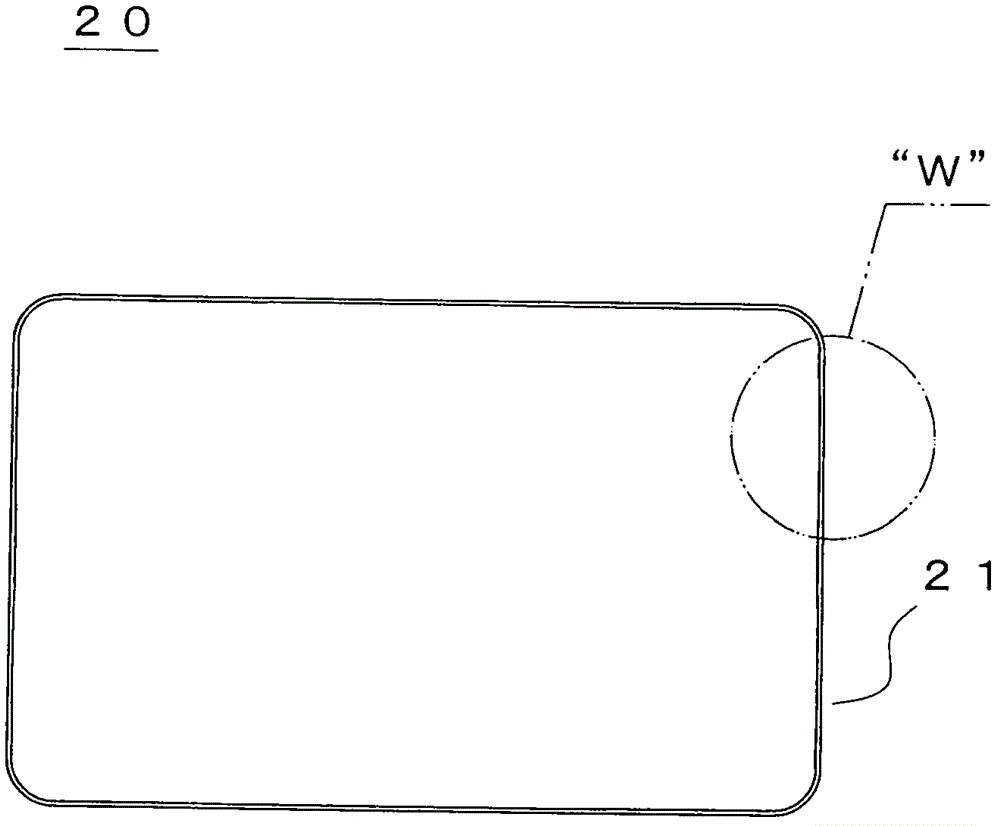

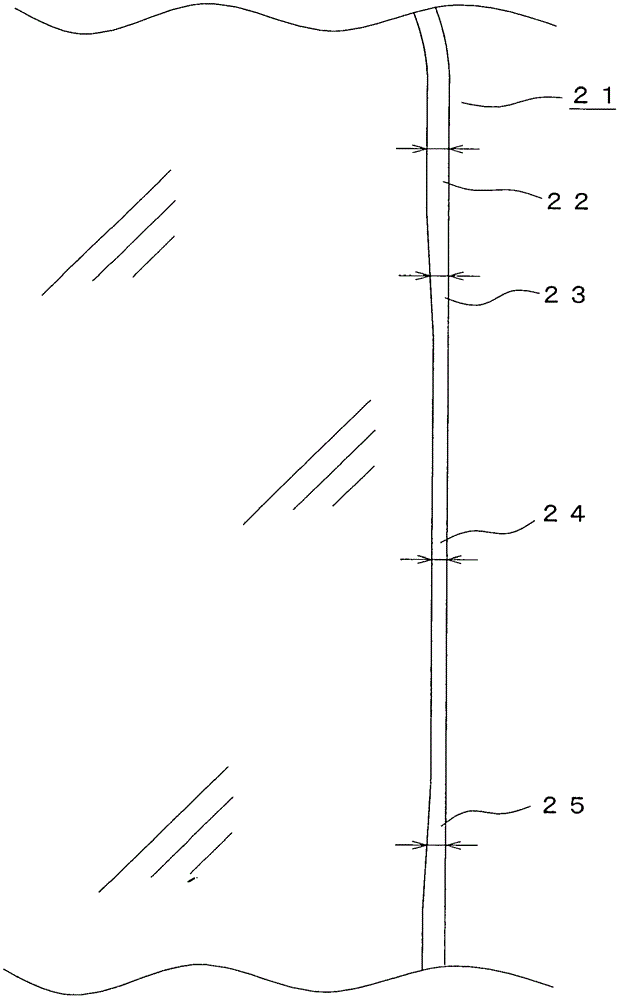

[0045] Referring to the drawings, the first panel 20 and the second panel 30 are connected by the panel connectors 10a and 10b to form the cooking oil removal panel structure 1 . The first panel 20 and the second panel 30 are press-formed iron plates, each having a rectangular sheet shape with rounded corners, and a first bead 21 having a winding diameter described later is formed on the entire circumference of the first panel 20. , a second bead 31 with a winding diameter of 3 mm is formed on the entire circumference of the second panel 30 . The first panel 20 is set to have a width of 600 mm and a width of 380 mm, and the second panel 30 is set to have a width of 380 mm and a width of 520 mm. In addition, the lower end of the first panel 20 is set at a position higher than the lower end of the second panel 30 by 175 mm.

[0046]In addition, the facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com