Sealing bearing system and its assembling method

A technology of sealing bearings and bearings, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as pollution, oil leakage and dust, and achieve the effects of reducing noise, preventing oil leakage, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The sealed bearing system of the present invention will be described in further detail below in conjunction with the accompanying drawings.

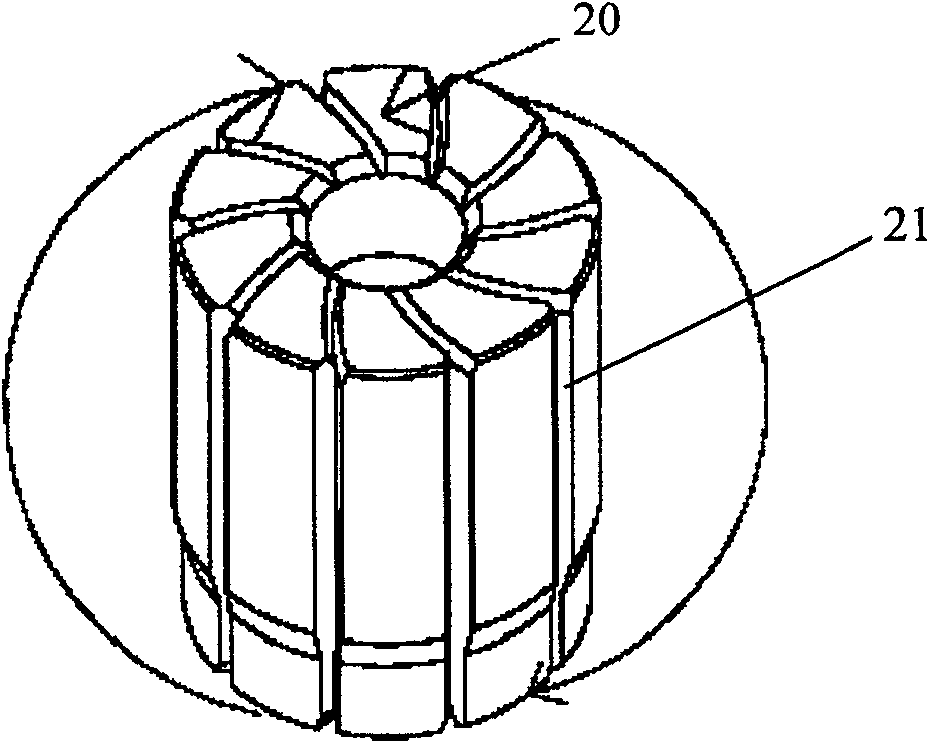

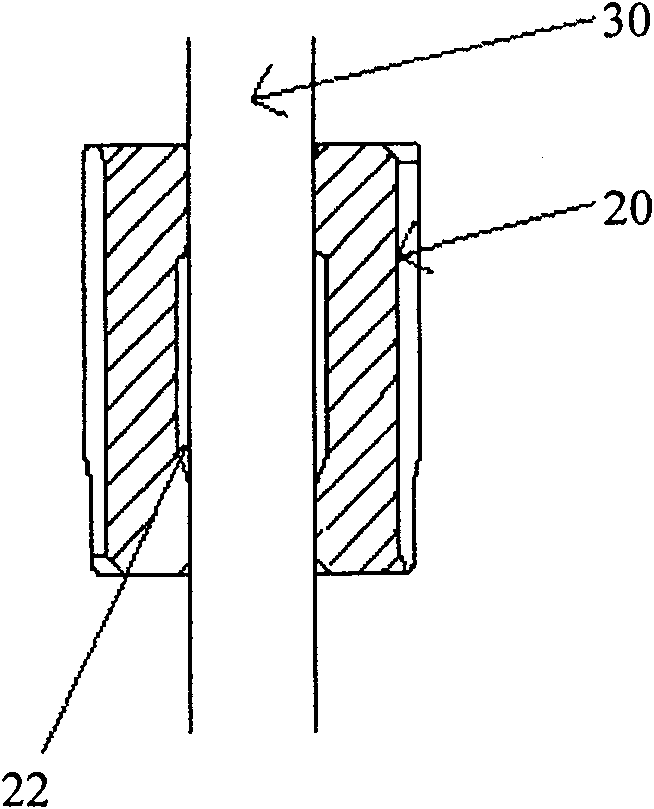

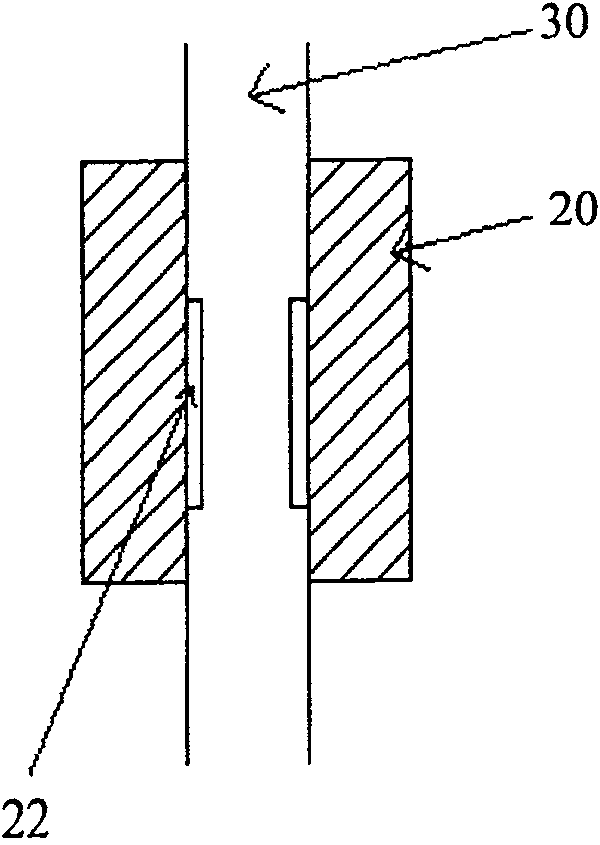

[0034] Such as Figure 5 Shown is an embodiment of the sealed bearing system of the present invention, including a hollow bearing housing 10 with two ends open, a sliding bearing 20 installed in the bearing housing 10, and one end extending through the sliding bearing 20 into the bearing housing The rotating shaft 30 of 10 and the sealing cover 40 and the sealing sleeve 50 respectively sealing the openings at both ends of the hollow bearing seat 10.

[0035] The bearing housing 10 forms a lubricating oil containing cavity 11 under the sealing of the sealing cover 40 and the sealing sleeve 50, and the lubricating oil can be sealed and stored in it, so that the sliding bearing 20 and the rotating shaft 30 are kept in good condition. Work under the best lubrication state to improve working life. The lower end opening of the bearing housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com