Highly effective electromagnetical spiral drying apparatus

A drying equipment and spiral technology, which is applied in the field of high-efficiency electromagnetic spiral drying equipment, can solve the problems of equipment aging energy consumption, long heating auxiliary time, and difficulty in controlling the moisture content of materials, so as to achieve less heat conduction loss and reduce maintenance investment in the later stage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

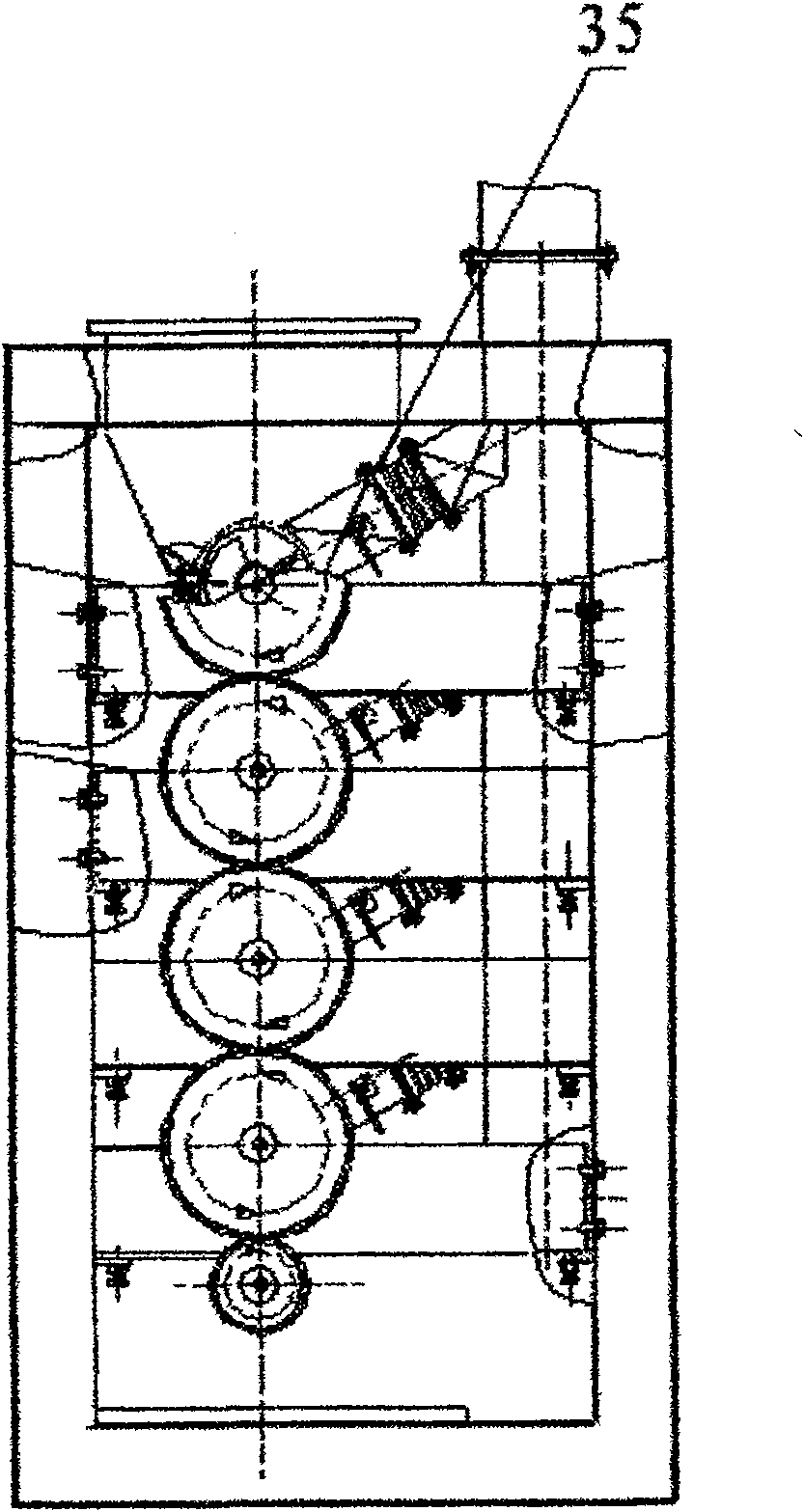

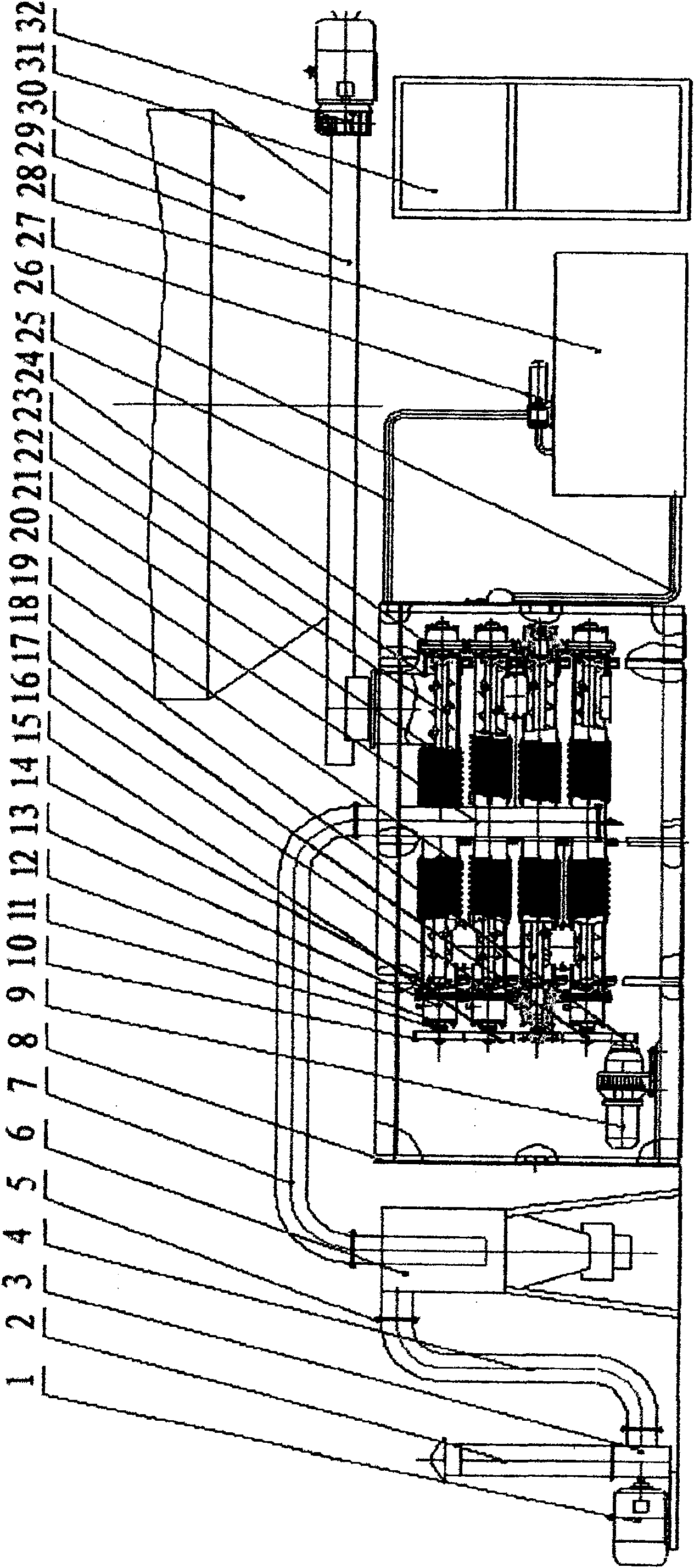

[0022] The specific implementation is as figure 1 and figure 2 As shown; the transmission stirring device fixed on the frame 8 includes a hollow tube distributed from top to bottom, inside the hollow tube there is a screw blade shaft 22 fixed along its tube axis, and the left and right ends of the screw blade shaft 22 are respectively connected with an input bearing seat 13 , Rear bearing seat 24; The input bearing gland 12 of the left end and the right end is sleeved on the two ends of the input bearing seat 13 and the rear bearing seat 24 and fixed by the lock nut 11. The left end of the helical blade shaft 22 is respectively axially connected with the first to fourth transmission gears 10, 14, 16, 17, and the teeth of the first to fourth transmission gears 10, 14, 16, 17 are meshed with each other. One end of each hollow tube has a feed port, and the other end has a discharge port, and the top hollow tube feed port communicates with the feed box 23 . The hollow tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com