Electromagnetic paddle drying equipment with self-cleaning function

A blade drying and electromagnetic technology, applied in the chemical, smelting and non-ferrous fields, can solve the problems of long heating auxiliary time, boiler safety, high labor intensity, etc., and achieve the effect of reducing heating auxiliary time, efficient heating function, and improving drying quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

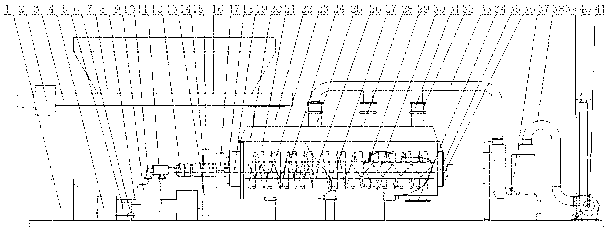

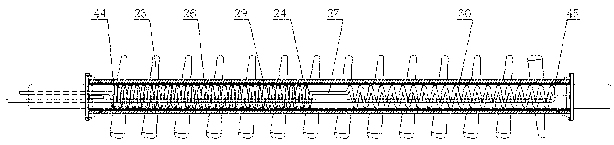

[0030] Electromagnetic paddle drying equipment with self-cleaning function, which at least includes a stirring propulsion mechanism, a drive mechanism, an import and export mechanism, and an electric control system. An electromagnetic coil is wound in the paddle hollow shaft 24 of the heating transmission stirring device.

Embodiment 2

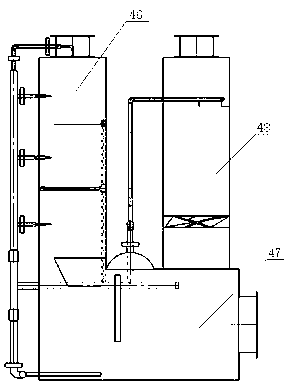

[0032] The electromagnetic paddle drying equipment with self-cleaning function is mainly composed of a stirring propulsion mechanism, a driving mechanism and an electric control system. There is a material inlet 22 on one side of the upper part of the stirring propulsion mechanism, and the other side of the upper part of the agitation propulsion mechanism has a moisture discharge outlet. One side of the propulsion mechanism is also connected with the transmission of the drive mechanism. In the stirring bin 21 of the stirring propulsion mechanism, 1-6 electromagnetic heating transmission stirring devices with the same structure are distributed, and each electromagnetic heating transmission stirring device includes a hollow electromagnetic paddle. Shaft 24, the left and right ends of the electromagnetic paddle hollow shaft 24 are respectively connected with the front bearing block 19 and the rear bearing block 35 bearings, the front bearing block 19 is connected with the drive mec...

Embodiment 3

[0035] When there are 2-6 electromagnetic heating transmission stirring devices, every two electromagnetic heating transmission stirring devices correspond to each other, and the propeller blades (23) between the two electromagnetic heating transmission stirring devices are mutually misaligned.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com