Method for improving efficiency of engine

An engine and efficiency technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as complicated design and verification process, unsatisfactory results, etc., to improve engine efficiency, reduce heat conduction loss, improve The effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

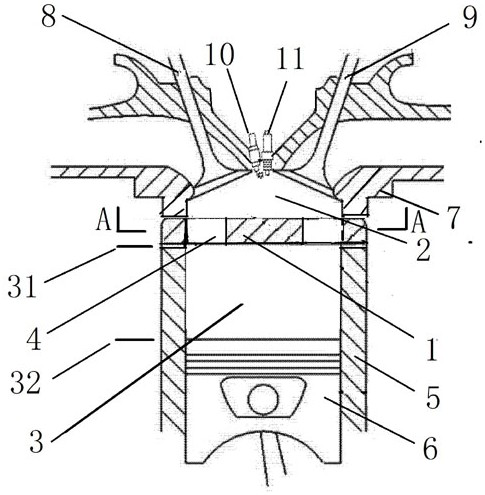

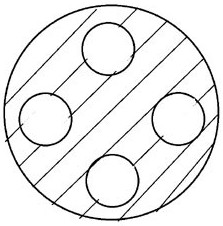

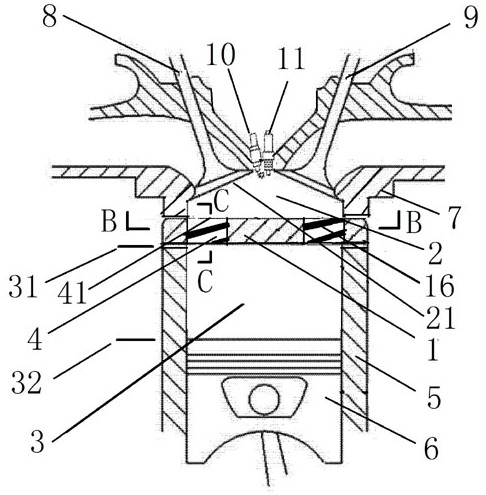

[0030] Specific embodiment two: the present invention is applied on two-stroke in-cylinder direct-injection gasoline engine:

[0031] Such as Image 6 , Figure 7 As shown, it is the application of the present invention on a two-stroke in-cylinder direct-injection gasoline engine. The partition plate 1 is arranged between the combustion chamber 2 and the piston movement space 3. The diversion channel 4 in the space 3 has spiral ribs 16 on the wall surface of the diversion channel 4, which promotes disturbance when the gas passes through; the top opening 41 of the diversion channel faces the wall 21 of the combustion chamber, and the gas enters from the piston movement space 3 When the combustion chamber 2 impacts the combustion chamber wall 21 and flows along the combustion chamber wall 21, the combustion chamber wall 21 is cooled; the diversion channel 4 is distributed in a circular oblique manner on the partition plate 1, so that the gas enters the combustion chamber 2 from...

specific Embodiment 3

[0034] Specific embodiment three: the present invention is applied on the injection gasoline engine at the entrance of the four-stroke intake valve:

[0035] Such as Figure 8 As shown, it is the application of the present invention on the injection gasoline engine at the entrance of the four-stroke intake valve, the partition plate 1 is arranged between the combustion chamber 2 and the piston movement space 3, and the partition plate 1 is provided with a communication chamber 2 and The diversion channel 4 in the piston movement space 3 has a top opening 41 facing the wall 21 of the combustion chamber, and the diversion channel 4 is distributed in a circular and oblique manner on the partition plate 1 .

[0036] During the intake stroke, the exhaust valve 9 is closed, the intake valve 8 is opened, the piston 5 moves from the top dead center 31 to the bottom dead center 32, and the air or the mixture of air and recirculated combustion exhaust gas is sucked into the combustion c...

specific Embodiment 4

[0040] Specific embodiment four: the present invention is applied on four-stroke diesel engine:

[0041] Such as Figure 9 As shown, for the application of the present invention on a four-stroke diesel engine, the partition plate 1 is arranged between the combustion chamber 2 and the piston movement space 3, and the partition plate 1 is provided with a guide connecting the combustion chamber 2 and the piston movement space 3. The flow channel 4 has spiral convex ribs 16 on the wall of the flow guide channel 4, which promotes disturbance when the gas passes through; the top opening 41 of the flow guide channel faces the combustion chamber wall 21, and when the gas enters the combustion chamber 2 from the piston movement space 3 Impact the wall 21 of the combustion chamber and flow along the wall 21 of the combustion chamber to cool the wall 21 of the combustion chamber; The inner macroscopically has a vortex shape.

[0042] During the intake stroke, the exhaust valve 9 is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com