Ignition system for high-power methanol engine and ignition method

A methanol engine and ignition system technology, applied in the ignition system field, can solve the problems of affecting engine emission performance, reducing engine economy, increasing engine leakage, etc., to achieve the goal of improving thermal efficiency and economy, increasing combustion speed, and improving thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

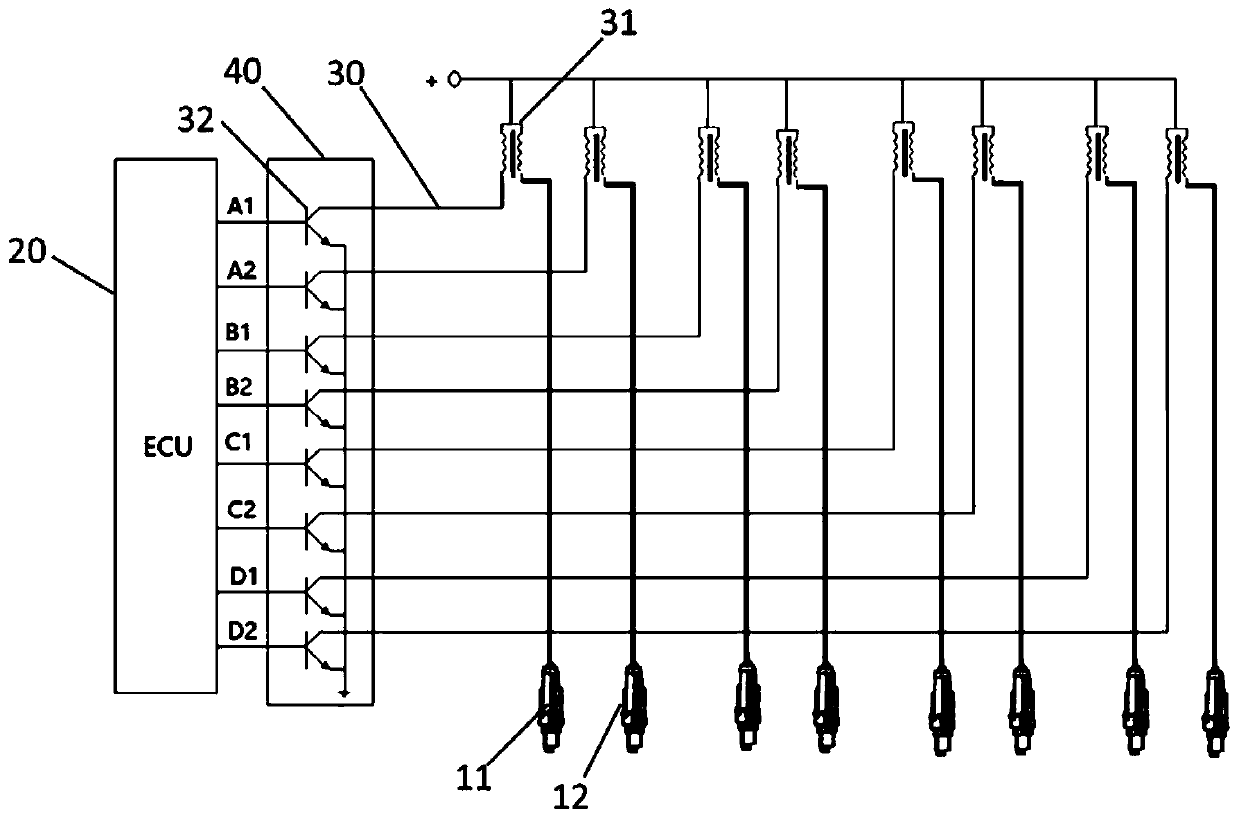

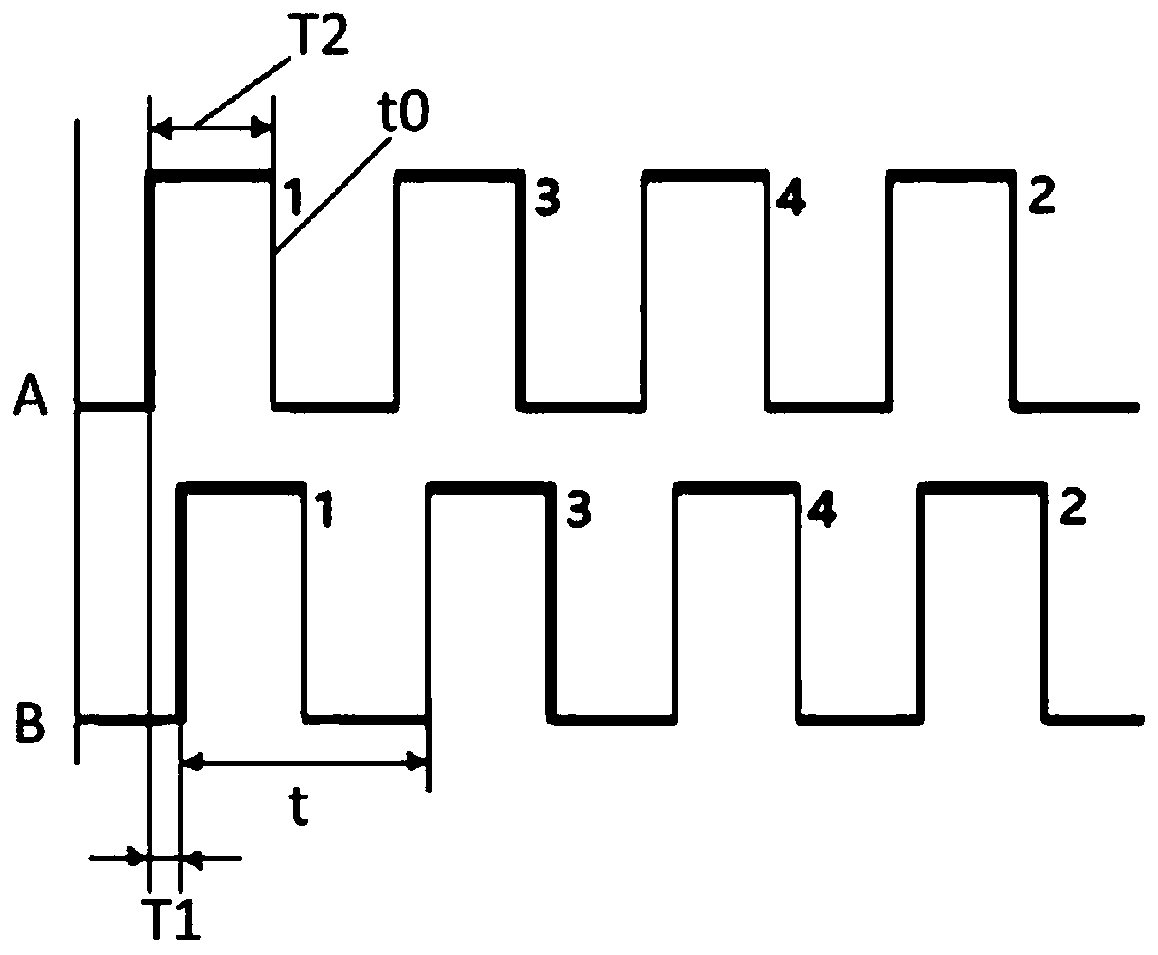

[0033] figure 1 It is a schematic diagram of an ignition system for a high-power methanol engine according to an embodiment of the present invention. Such as figure 1 As shown, in one embodiment, the ignition system for a high-power methanol engine of the present invention includes multiple sets of spark plugs and a controller 20 . Multiple sets of spark plugs are respectively arranged on the cylinder heads of the high-power methanol engines, and each set of spark plugs includes a main spark plug 11 and a secondary spark plug 12 . The controller 20 is used to control each group of spark plugs to ignite sequentially in a preset order, and to control the auxiliary spark plug 12 of each group of spark plugs to delay the ignition for a preset time T1 after the main spark plug 11 is ignited, and the preset time T1 is to burn after ignition of each group of spark plugs. It is obtained through a calibration experiment with the goal of maximizing work, for example, through engine th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com