Steel casting wet type sand binding bright desand composite powder additive

A technology of green sand and additives, applied in the direction of casting molds, casting molding equipment, cores, etc., can solve the problems of difficult to guarantee the quality of castings, high production costs, pollution of the environment, etc., and achieve the effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

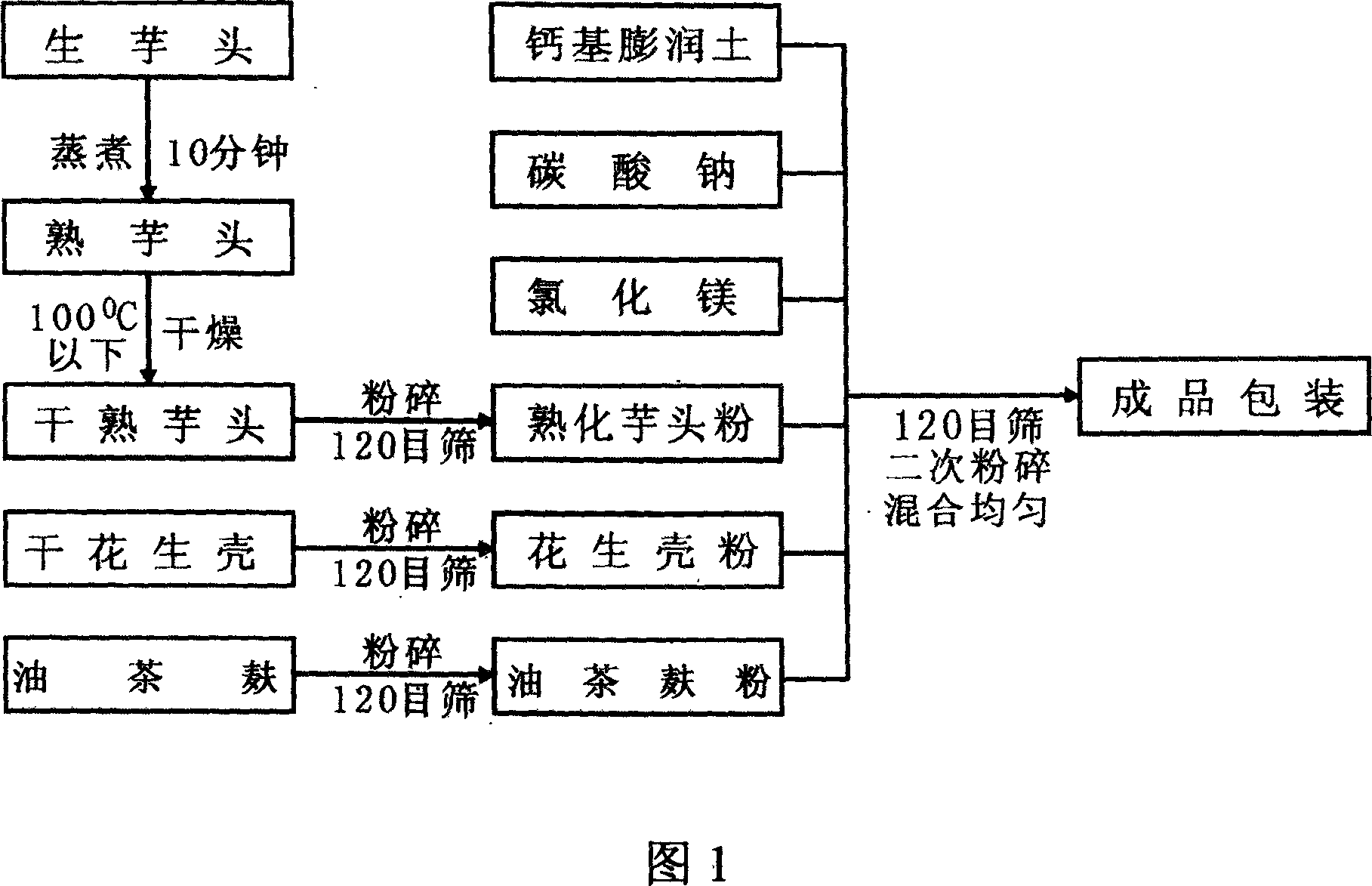

[0021] To produce 1000kg of this iron and steel casting green sand bonding, brightening, and de-sanding compound powder additive, weigh 200kg of cooked taro powder, 250kg of calcium-based bentonite, 50kg of sodium carbonate, and camellia oleifera bran powder by cooking, drying and pulverizing raw taro. 200kg of magnesium chloride, 50kg of magnesium chloride, and 250kg of peanut shell powder are mixed and smashed through a 120-mesh sieve. When used in a foundry, add 100 parts of raw foundry sand by weight to 6 to 8 parts of this powder and 6 to 7 parts of water. Mixing and grinding for 6 to 8 minutes, the sand is produced for use or stand-by, and the operation of one-time, one-shot, in-place sand mixing is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com