Cross-linking type wet mixed mortar plasticizer and preparation method thereof

A wet-mixed mortar and plasticizer technology, which is applied in the field of building admixtures, can solve the problems of insufficient water retention rate and long-term stability of compressive strength of plasticizers, and achieves enhanced steric hindrance effect, high conversion rate, and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

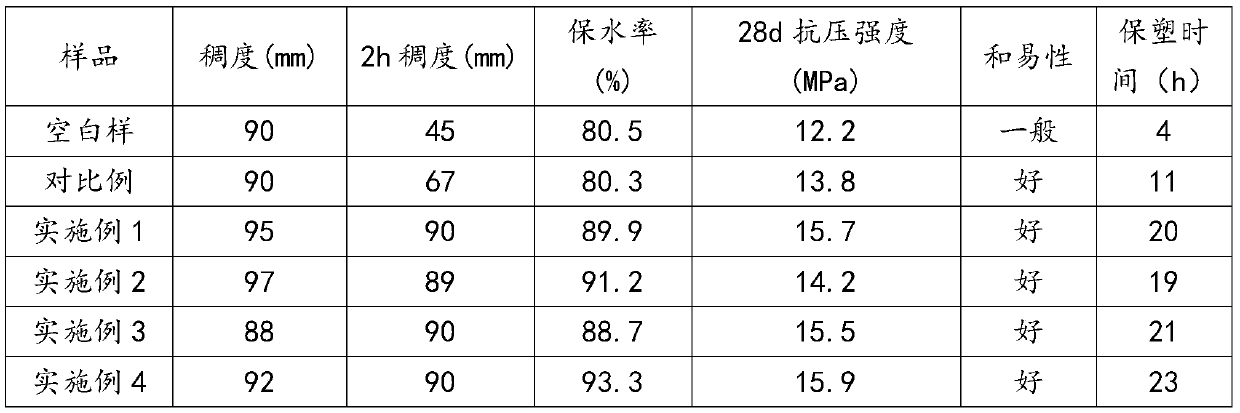

Examples

Embodiment 1

[0032] (1) The first esterification reaction: 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 50g of prenyl alcohol are added to the reaction vessel, the temperature is raised to 80°C, and then 2g of aluminum sulfate octahydrate is added, After reacting for 3 hours, the excess prenol was removed by reflux to obtain prenyl 2-amino-3-p-hydroxyphenylpropionate.

[0033] (2) The second esterification reaction:

[0034] Add 100g of 3-hydroxyphenylphosphonopropionic acid and cyclohexane into the reaction kettle, then add 100g of dihydromyrcenol, add p-732 cation exchange resin and hydroquinone at the same time, stir evenly, and then raise the temperature to 30°C, react for 2 hours, filter and distill at atmospheric pressure to get 3-hydroxyphenyl phosphatopropionate dihydromyrcenyl;

[0035] Wherein, the dosage of 732 cation exchange resin is 0.5% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 0.5% of the mass of 3-hydroxyphenylphosphorylpr...

Embodiment 2

[0039] (1) The first esterification reaction: 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 100g of propylene alcohol were added to the reaction vessel, the temperature was raised to 90°C, and then 2g of ferric ammonium sulfate dodecahydrate was added, After reacting for 3 hours, excess propenol was removed by reflux to obtain 2-amino-3-propenyl p-hydroxyphenylpropionate.

[0040] (2) The second esterification reaction:

[0041]Add 100g of 3-hydroxyphenylphosphonopropionic acid and cyclohexane into the reaction kettle, then add 200g of dihydromyrcenol, add p-732 cation exchange resin and hydroquinone at the same time, stir evenly, and then raise the temperature to 50°C, react for 3 hours, filter and distill at atmospheric pressure to get 3-hydroxyphenyl phosphatopropionate dihydromyrcenyl;

[0042] Wherein, the dosage of 732 cation exchange resin is 1% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 0.5% of the mass of 3-hydroxypheny...

Embodiment 3

[0046] (1) The first esterification reaction: add 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 150g of prenyl alcohol into the reaction vessel, raise the temperature to 70°C, and then add 3g of sodium bisulfate monohydrate , reacted for 4 hours, and refluxed to remove excess prenyl alcohol to obtain prenyl 2-amino-3-p-hydroxyphenylpropionate.

[0047] (2) The second esterification reaction:

[0048] 100g of 3-hydroxyphenylphosphorylpropionic acid and cyclohexane are added to the reaction kettle, then 250g of dihydromyrcenol is added, and p-732 cation exchange resin and hydroquinone are added simultaneously, stirred evenly, and then the temperature is raised to 60°C, react for 3 hours, filter and distill under normal pressure to get 3-hydroxyphenyl phosphatopropionate dihydromyrcenyl;

[0049] Wherein, the dosage of 732 cation exchange resin is 1.5% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 1% of the mass of 3-hydroxyphenylphos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com