Stabilizer-plasticizer for wet mixed mortar and preparation method thereof

A technology of wet-mixed mortar and plastic stabilizer, which is applied in the field of construction admixtures, can solve the problem of insufficient plasticity of the plastic stabilizer, and achieve the effects of enhanced steric hindrance effect, increased adsorption capacity, and good plastic retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

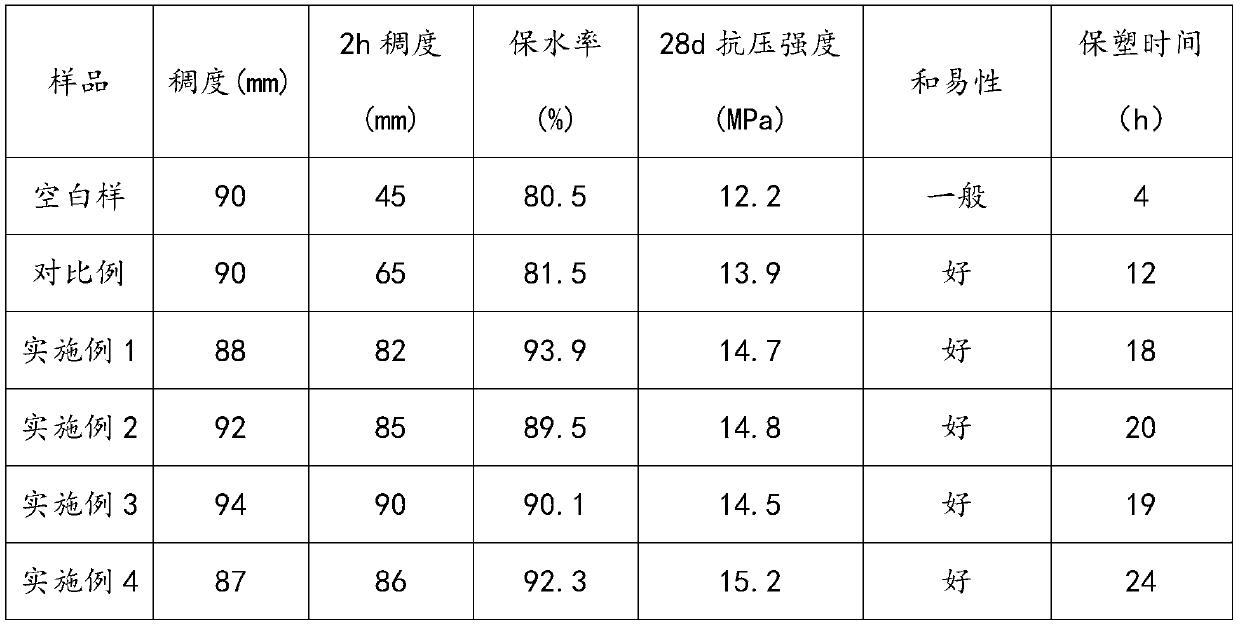

Examples

Embodiment 1

[0030] (1) The first esterification reaction:

[0031] Add 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 50g of propylene alcohol into the reaction vessel, raise the temperature to 80°C, then add 2g of ferric ammonium sulfate dodecahydrate, react for 3 hours, reflux the excess propylene Removal of the alcohol yields 2-amino-3-propenyl p-hydroxyphenylpropionate.

[0032] (2) The second esterification reaction:

[0033] Add 100g of 3-hydroxyphenylphosphorylpropionic acid and cyclohexane into the reaction kettle, then add 100g of dihydromyrcenol, add p-732 cation exchange resin and hydroquinone at the same time, stir evenly, and then raise the temperature to to 30°C, react for 2 hours, filter and distill under atmospheric pressure to obtain 3-hydroxyphenyl phosphine propionate dihydromyrcenyl;

[0034] Wherein, the dosage of 732 cation exchange resin is 0.5% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 0.5% of the mass of 3-hydroxyp...

Embodiment 2

[0039] (1) The first esterification reaction:

[0040] Add 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 100g of butenyl alcohol into the reaction vessel, raise the temperature to 90°C, then add 1g of sodium bisulfate monohydrate, react for 4 hours, reflux to remove the excess butanol Removal of the enol yields butenyl 2-amino-3-p-hydroxyphenylpropionate.

[0041] (2) The second esterification reaction:

[0042] Add 100g of 3-hydroxyphenylphosphonopropionic acid and cyclohexane into the reactor, then add 200g of dihydromyrcenol, add 732 cation exchange resin and hydroquinone at the same time, stir evenly, and then raise the temperature to 50°C, react for 3 hours, filter and distill at atmospheric pressure to get 3-hydroxyphenyl phosphatopropionate dihydromyrcenyl;

[0043] Wherein, the dosage of 732 cation exchange resin is 1% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 0.5% of the mass of 3-hydroxyphenylphosphorylpropionic acid...

Embodiment 3

[0048] (1) The first esterification reaction:

[0049] Add 50g of 2-amino-3-p-hydroxyphenylpropionic acid and 150g of unsaturated alcohol into the reaction vessel, raise the temperature to 80-90°C, then add 1-3 parts by weight of catalyst, react for 2 to 5 hours, and reflux The excess prenol is removed to give 2-amino-3-p-hydroxyphenylpropionate.

[0050] (2) The second esterification reaction:

[0051] Add 100g of 3-hydroxyphenylphosphonopropionic acid and cyclohexane into the reactor, then add 250g of dihydromyrcenol, add 732 cation exchange resin and hydroquinone at the same time, stir evenly, and then raise the temperature to 60°C, react for 3 hours, filter and distill under normal pressure to get 3-hydroxyphenyl phosphatopropionate dihydromyrcenyl;

[0052] Wherein, the dosage of 732 cation exchange resin is 1.5% of the mass of 3-hydroxyphenylphosphorylpropionic acid, the dosage of hydroquinone is 1% of the mass of 3-hydroxyphenylphosphorylpropionic acid, and the atmosp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com