Chlorion-free amphiprotic polycarboxylic acid high-performance water reducing agent and preparation method thereof

An amphoteric, polycarboxylic acid technology, used in the field of concrete admixture synthesis, can solve the problems of poor dispersibility and water-reducing effect, low early compressive strength, steel corrosion hazards, etc., to eliminate steel corrosion and excellent plastic retention performance. , the effect of no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

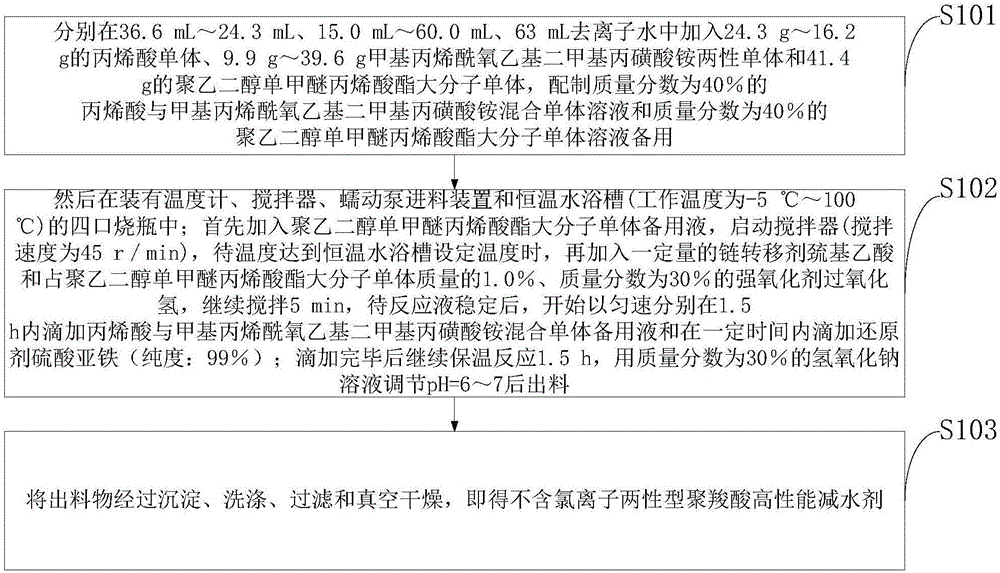

[0037] Such as figure 1 As shown, the preparation method of the chlorine ion-free amphoteric polycarboxylate high-performance water reducer provided by the embodiment of the present invention includes the following steps:

[0038] S101: Add 24.3g to 16.2g of acrylic acid monomer and 9.9g to 39.6g of ammonium methacryloyloxyethyldimethylpropanesulfonate in 36.6mL-24.3mL, 15.0mL-60.0mL, and 63mL of deionized water, respectively Amphoteric monomer and 41.4g of polyethylene glycol monomethyl ether acrylate macromer, the preparation mass fraction is the mixed monomer solution and mass fraction of acrylic acid and methacryloyloxyethyl dimethyl propane sulfonate ammonium The fraction is 40% polyethylene glycol monomethyl ether acrylate macromer solution for standby;

[0039] S102: Then, in a four-necked flask equipped with a thermometer, a stirrer, a peristaltic pump feeding device and a constant temperature water bath (working temperature is -5°C to 100°C); first add polyethylene g...

Embodiment 1

[0048] Add 24.3g of acrylic acid monomer, 9.9g of ammonium methacryloxyethyl dimethyl propanesulfonate amphoteric monomer and 41.4g of polyethylene glycol monomethyl ether into 36.6mL, 15.0mL, and 63mL of deionized water, respectively. Acrylate macromolecular monomer, the preparation mass fraction is 40% the mixed monomer solution of acrylic acid and methacryloyloxyethyl dimethyl propane sulfonate ammonium and the mass fraction is 40% polyethylene glycol monomethyl ether acrylate The macromolecular monomer solution is ready for use; then in a four-necked flask equipped with a thermometer, a stirrer, a peristaltic pump feeding device and a constant temperature water bath (working temperature is -5°C to 100°C), first add polyethylene glycol monomethanol Ether acrylate macromer standby liquid, start the stirrer (stirring speed is 45r / min), when the temperature reaches the set temperature of the constant temperature water bath, add a certain amount of chain transfer agent thioglyco...

Embodiment 2

[0058] It is basically the same as Example 1, the difference is:

[0059] Preferably, the chain transfer agent thioglycolic acid used in the step is 1.2% (accounting for the total mass of the reaction monomers).

[0060] Preferably, the mass ratio of the strong oxidant hydrogen peroxide to the reducing agent ferrous sulfate in the step is 0.9:1.

[0061] Preferably, the time for adding the reducing agent ferrous sulfate in the step is 1.5h.

[0062] Preferably, the reaction temperature in the step is 10°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com