Fixing clamp for shaft sleeve

A technology for fixing fixtures and shaft sleeves, which is applied in the direction of clamping, positioning devices, and manufacturing tools. It can solve the problems of shaft and sleeve locking, high scrap rate, and low efficiency, so as to ensure coaxiality and improve the authenticity rate. , The effect of convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

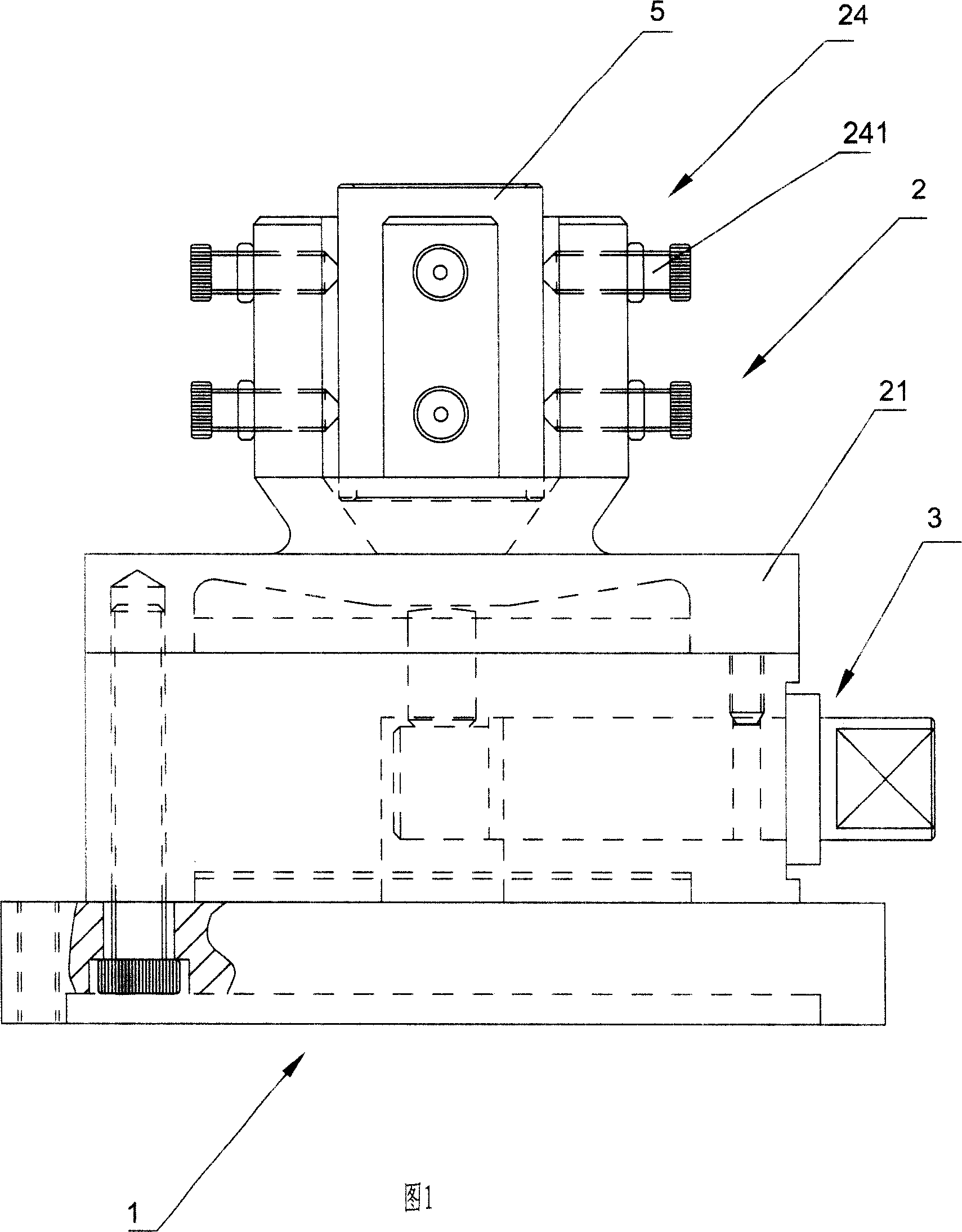

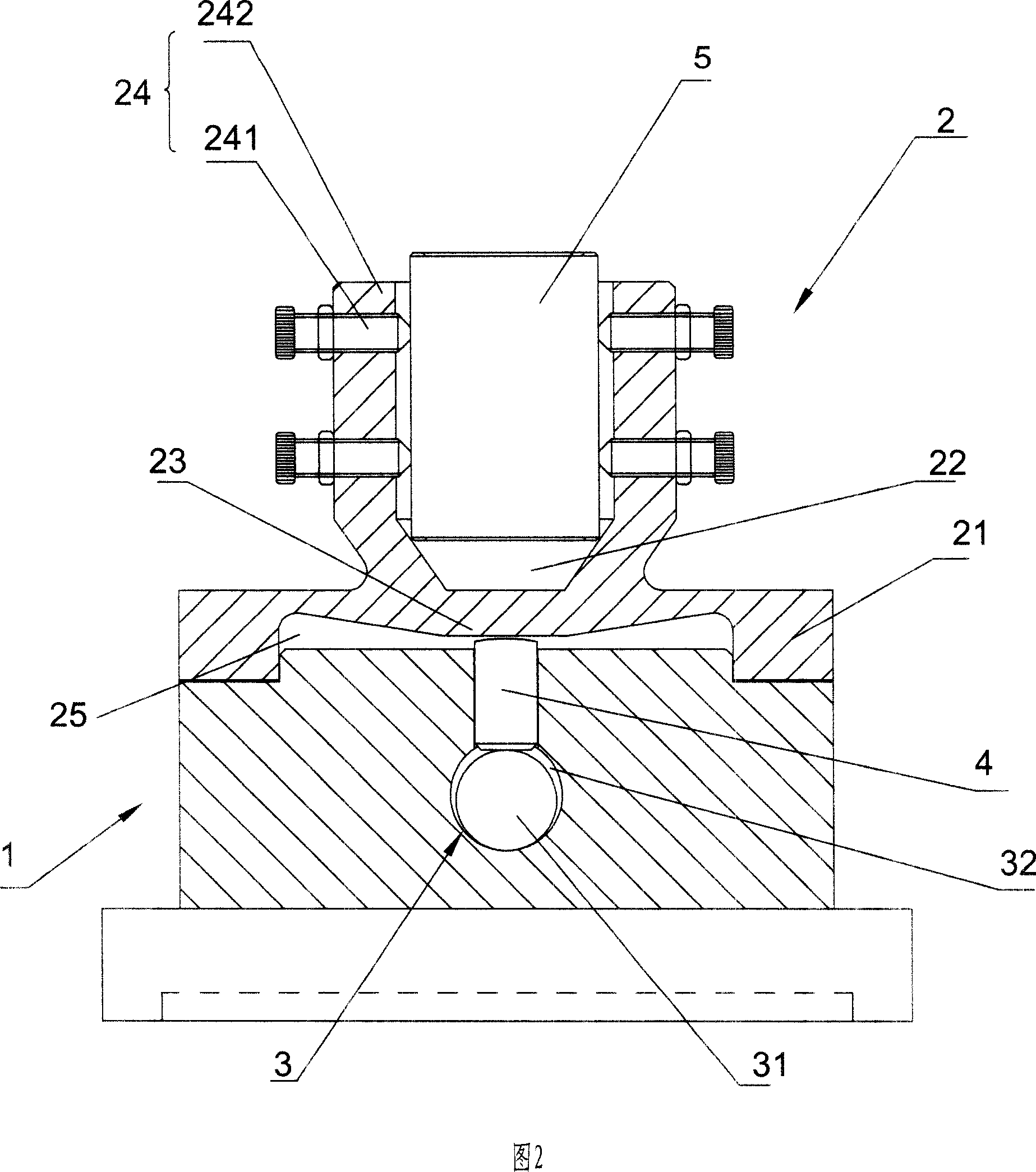

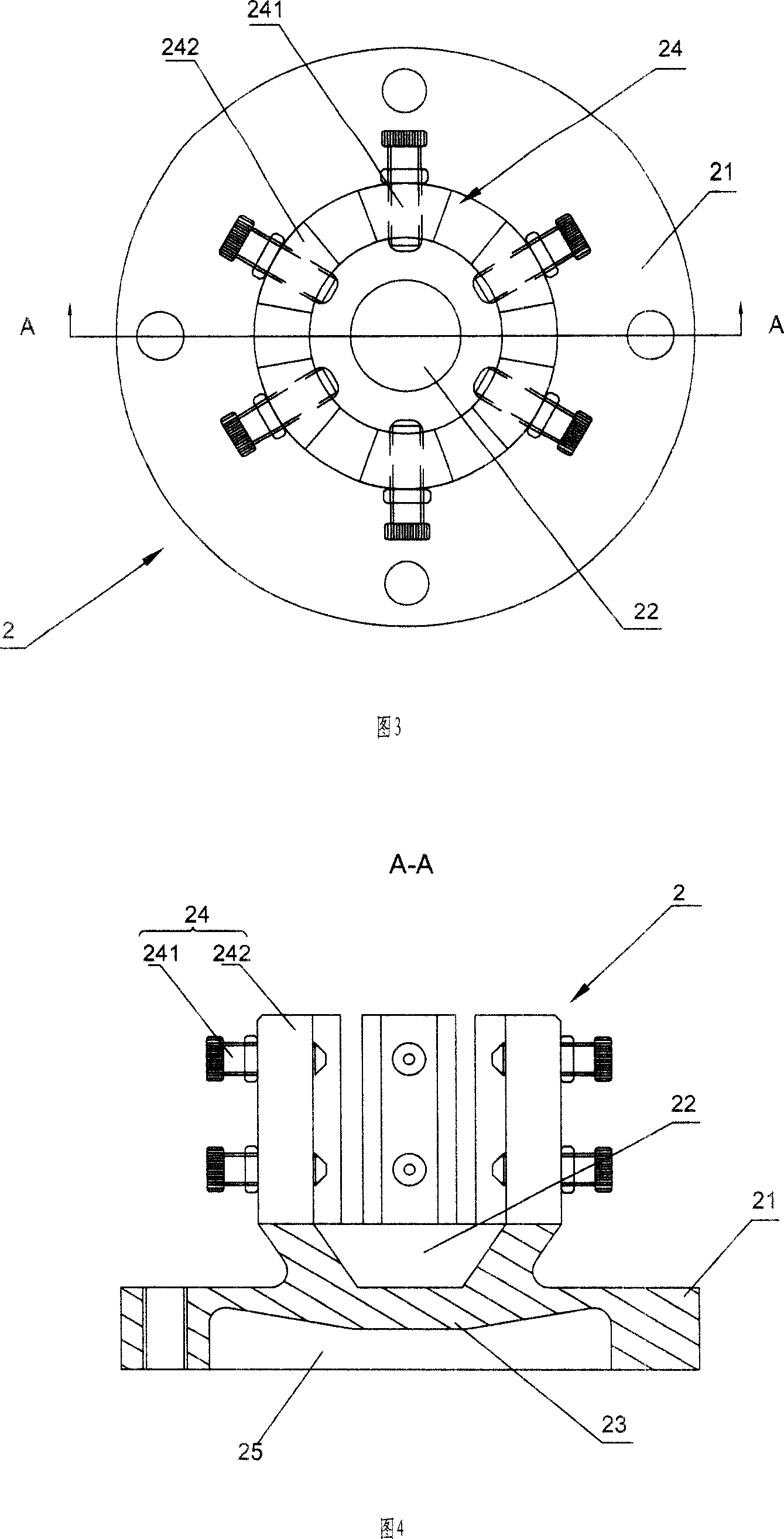

[0015] Referring to accompanying drawings 1 to 5, a shaft sleeve fixing fixture includes a seat body 1, a clip body 2 fixedly arranged above the seat body 1, and is located between the seat body 1 and the clip body 2 and can be positioned along its own axis. The push rod 4 that moves in the direction of the heart line. Wherein, the clip body 2 includes a base 21 and a plurality of claws 24 arranged on the base 21 for clamping the workpiece 5, and the upper part of the base 21 is provided with a tapered hole 22 whose longitudinal section is truncated and inverted conical (in this specification The described "up", "down" positional relationship corresponds to the upper and lower positional relationship shown in accompanying drawing 1), the axis line of the taper hole 22 coincides with the axis line of the ejector rod 4, and a plurality of claws 24 are evenly distributed on a circle, and the center of the circle is located on the axis of the tapered hole 22 . A cavity 25 is dug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com