Operating mechanism of automobile hand brake

A control mechanism and hand brake technology, applied in the field of automobile hand brake control mechanism, can solve problems such as occurrence of danger, and achieve the effects of low cost, avoidance of danger and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

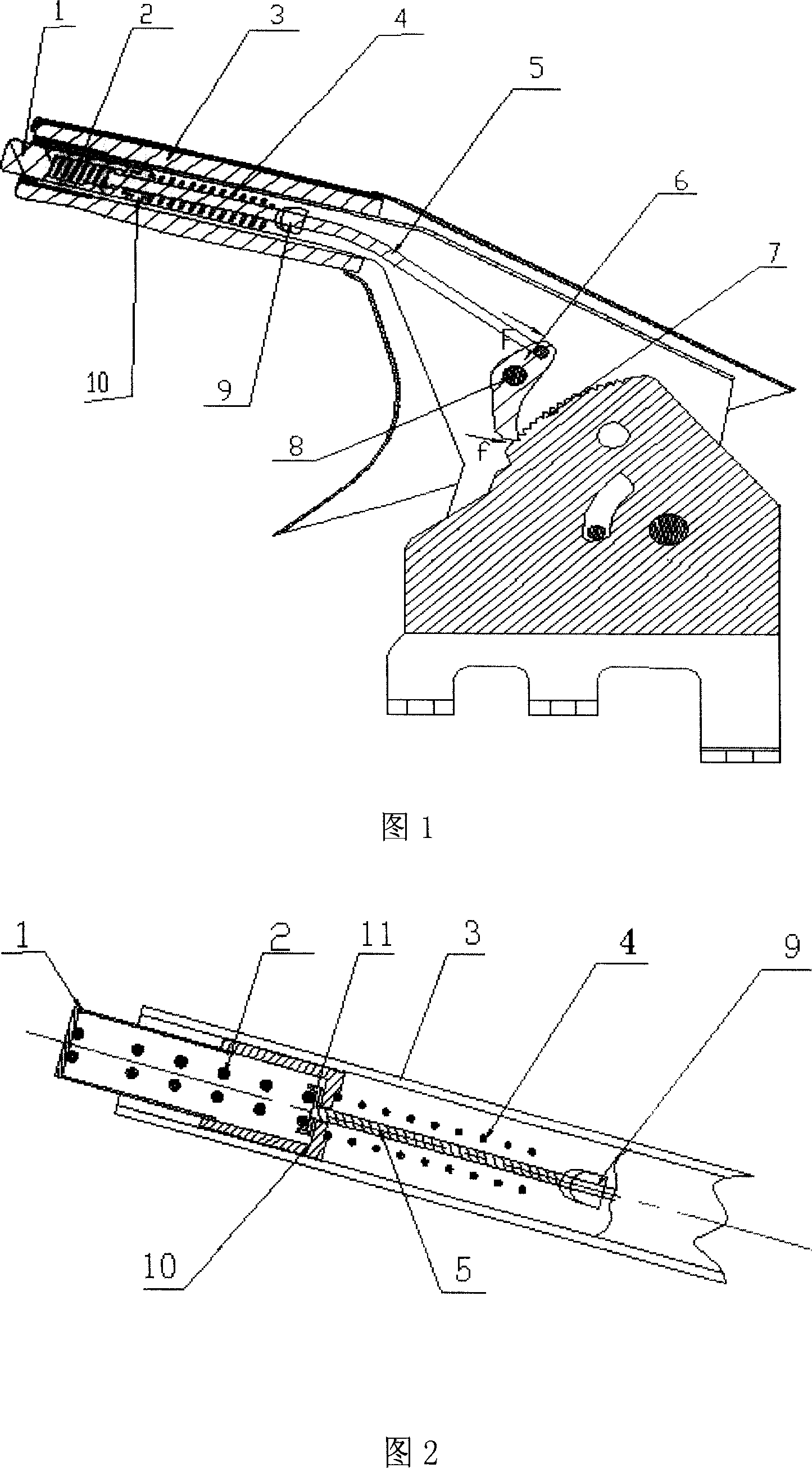

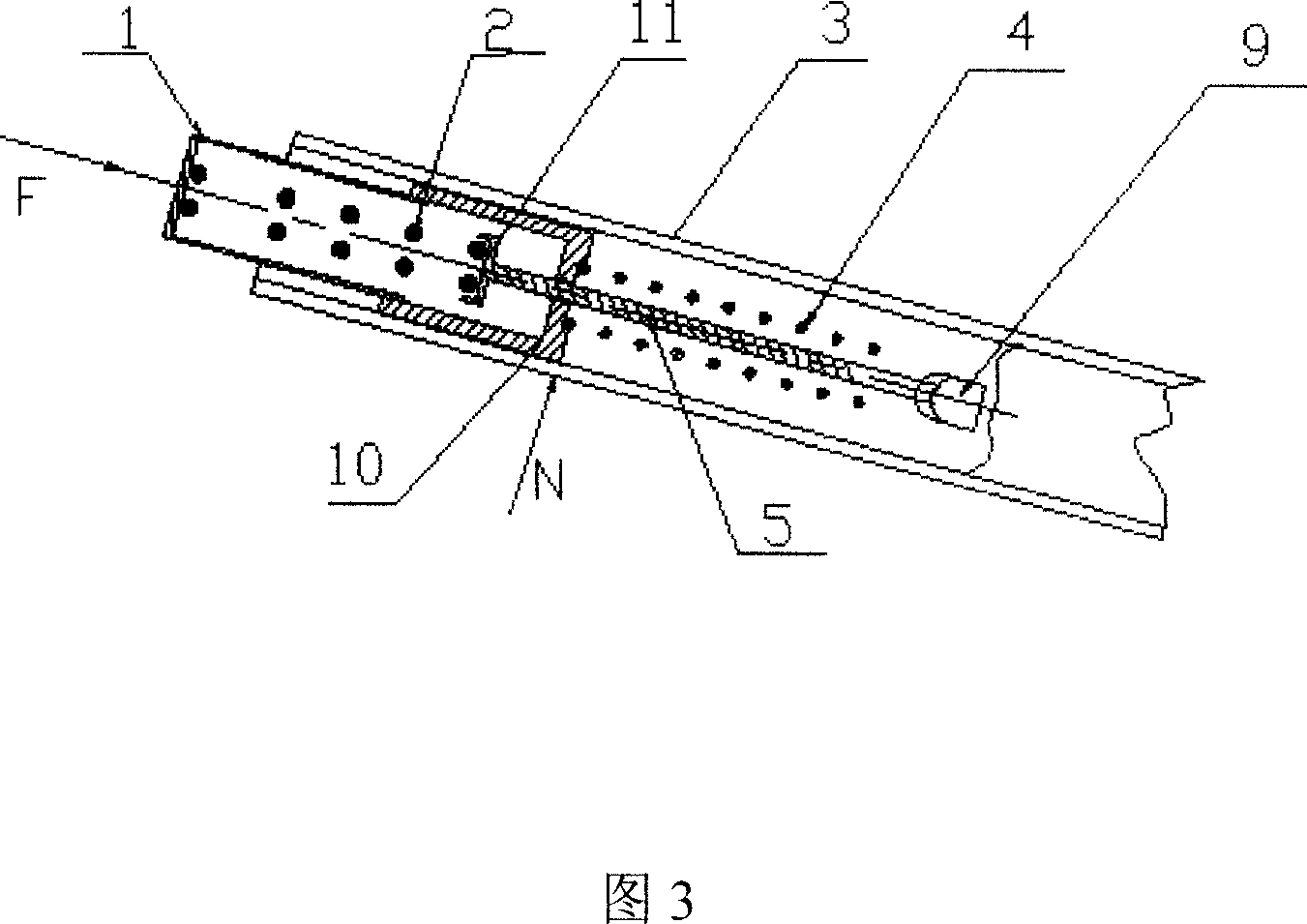

[0013] As shown in Fig. 1 and Fig. 2, the automobile hand brake control mechanism of the present invention comprises a handle 3, a button 1, a hand brake push rod 5, a ratchet 6 and a toothed plate 7 with ratchet teeth, and the toothed plate 7 is fixed on the vehicle body floor , the ratchet 6 is fixed on the rear end of the handle 3 by the rotating shaft 8, and its pawl cooperates with the ratchet on the tooth plate 7. The hand brake push rod 5 is installed in the through hole in the middle of the handle 3, and the end of the hand brake push rod 5 Hinged with the ratchet 6, the through hole of the handle 3 is provided with a return spring 4 that makes the hand brake push rod 3 return to the front end of the handle and a spring clamp 9 that is fixed in the handle 3 to position the spring, and the hand brake push rod The front end of 5 has a sliding spring seat 10 that is set on the hand brake push rod and acts on the return spring 4; the front end of the hand brake push rod 5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com