Surface adhesion type overcurrent protection element

A technology of protection components and surface adhesion, which is applied in the field of surface adhesion type overcurrent protection components, can solve problems such as difficulty in carrying current, and achieve the effect of high carrying current and low resistance carrying current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

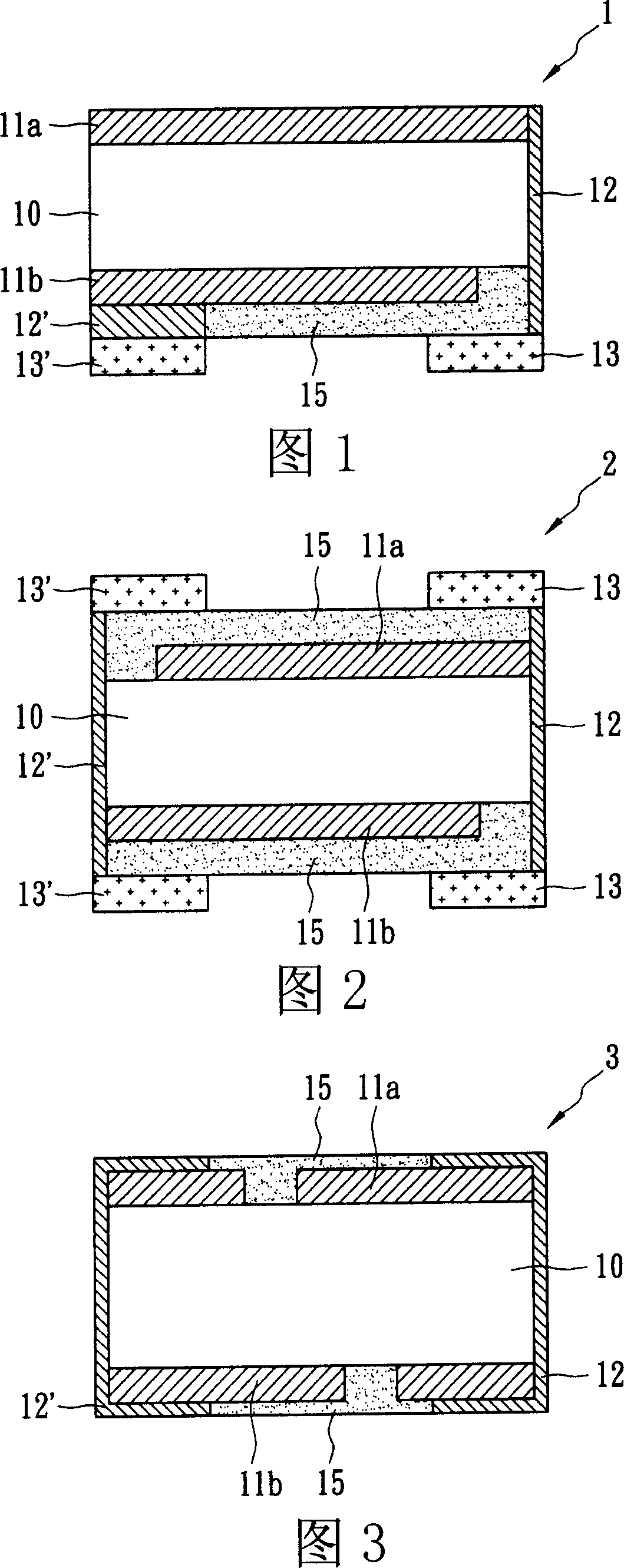

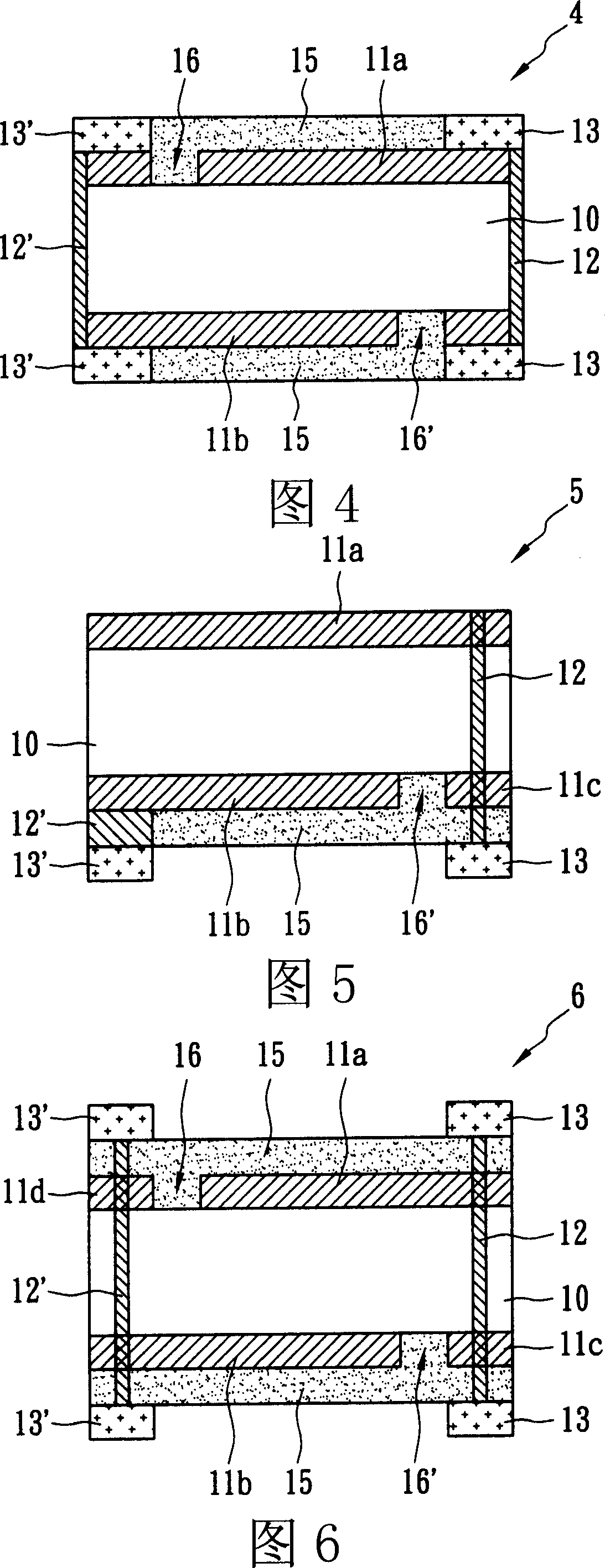

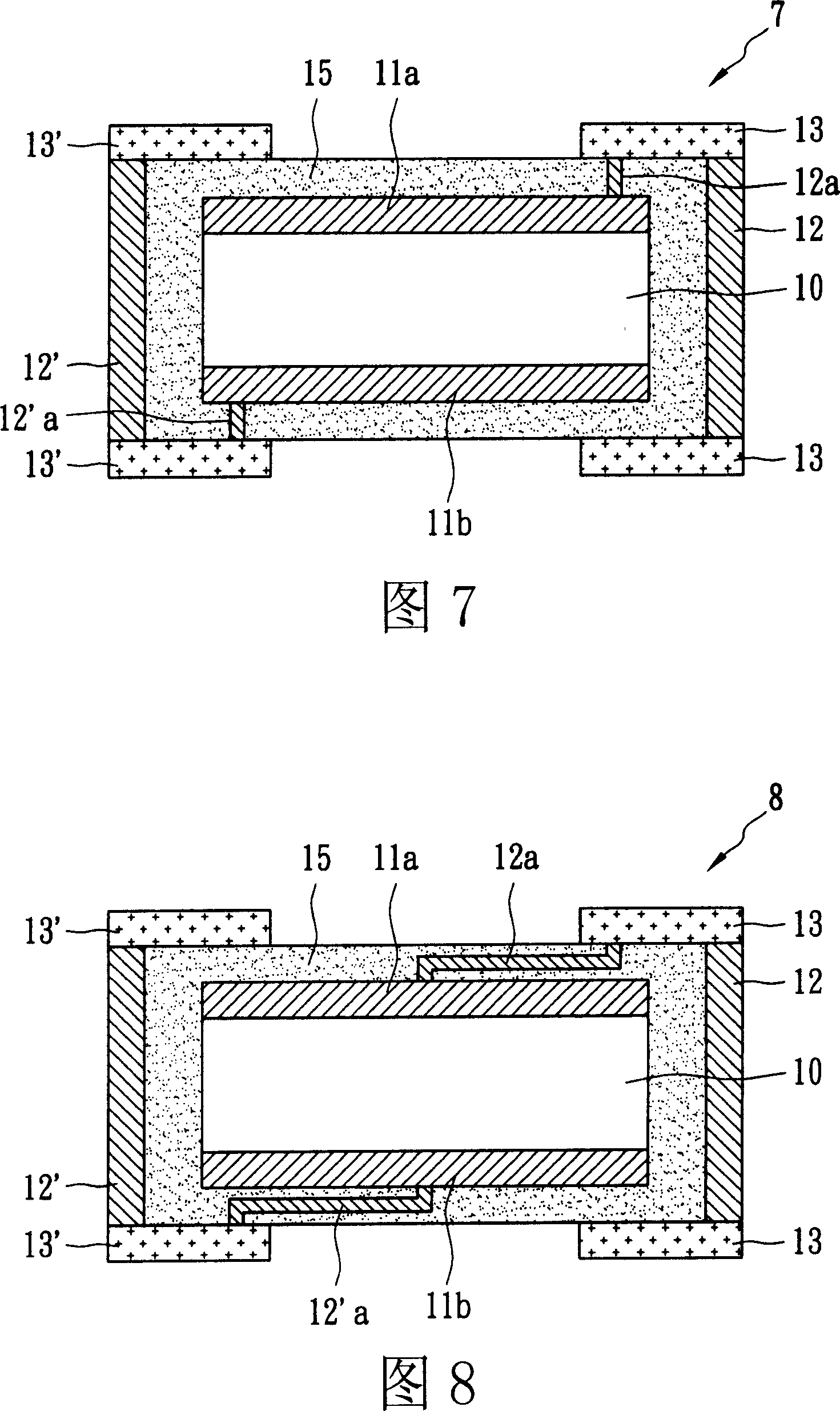

[0018] The structure, composition and manufacturing process of each embodiment of the overcurrent protection element of the present invention will be described below with reference to the accompanying drawings.

[0019] FIG. 1 is a schematic diagram of a surface mount overcurrent protection device 1 according to a first embodiment of the present invention, which is used to be adhered to the surface of a substrate (not shown). The first metal electrode 13 and the second metal electrode 13' corresponding to the first metal electrode 13 are generally located on the same plane. The surface mount type overcurrent protection element 1 can be designed to only include a set of electrode groups consisting of a first metal electrode 13 and a second metal electrode 13', so that the surface mount type overcurrent protection element 1 can only have one A specific face is bonded to the substrate surface. This design is usually used in narrow spaces, and needs to achieve unidirectional heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com