Metallic copper particles, and production method therefor

A technology of copper particles and metal, which is applied in the field of metallic copper particles, can solve problems such as the inability to easily prepare metallic copper particles, and achieve the effect of low volume resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

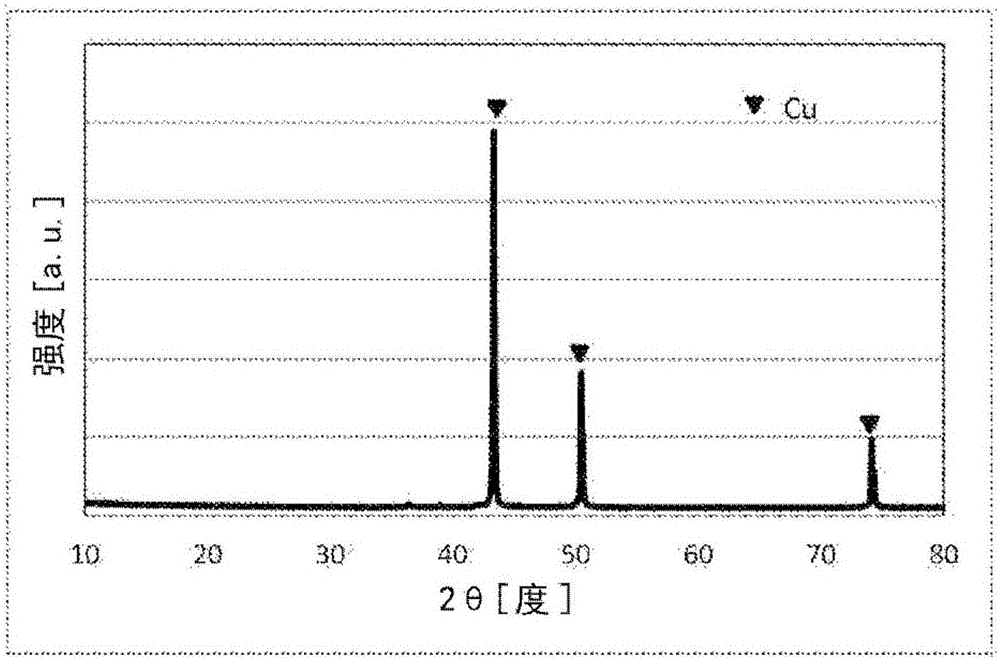

Embodiment 1

[0216] To 150 ml of pure water, 24 g of industrial copper(II) oxide (N-120 manufactured by NC-Tech Co., Ltd.) and 9.55 g of gelatin (amine value of 23, acid value of 29) as a protective colloid were added. value, amine value-acid value=-6, and a mass average molecular weight of 200000) and mixed, and the temperature of the mixed solution was raised to 80°C. After the temperature was raised, a solution prepared by mixing 1.2 g of aminoethanol as a complexing agent and 99 g of 50% hypophosphorous acid in 150 ml of pure water was added to the mixed solution under stirring, and the resulting mixture was mixed with copper oxide The reaction was performed for one hour, and then the reaction solution was aged for two hours to prepare gelatin-coated copper particles. Thereafter, the copper particles were filtered and washed until the specific conductivity of the filtrate reached below 100 μS / cm, and dried at a temperature of 60° C. under a nitrogen atmosphere for 10 hours to obtain me...

Embodiment 2 to 5

[0218] Metallic copper particles (samples B to E) according to the present invention were obtained in the same manner as in Example 1 except that the amount of gelatin in Example 1 was changed to the amount described in Table 1.

Embodiment 6 to 7

[0220] Metallic copper particles (samples F to G) according to the present invention were obtained in the same manner as in Example 1, except that the reaction temperature set at 80°C in Example 1 was changed to 60°C or 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com