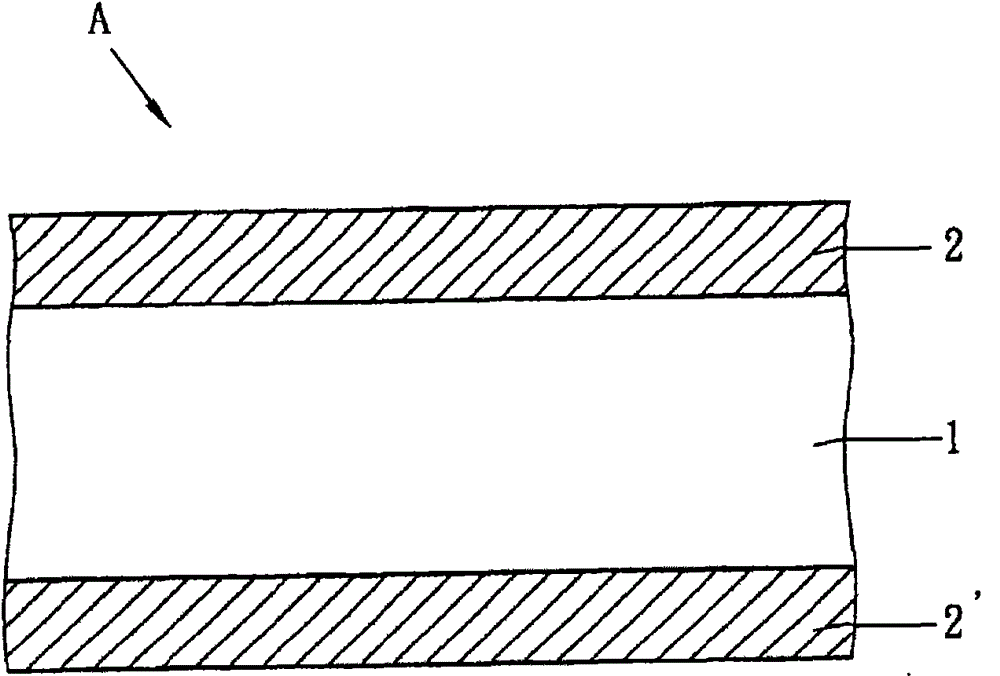

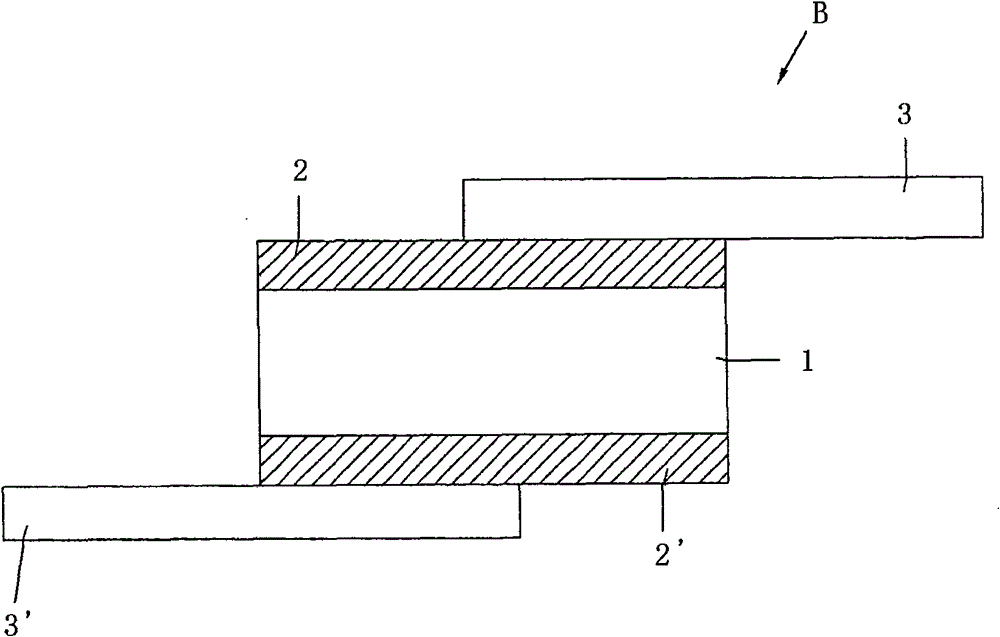

Overcurrent Protection Components

A technology for protecting components and overcurrent, applied in the direction of current-responsive resistors, resistors with positive temperature coefficient, etc., can solve the problems of complex process, can not guarantee the complete encapsulation of products, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The composition and weight (unit: gram) of the PTC material layer used in the overcurrent protection element of the present invention are shown in Table 1.

[0044] Table 1

[0045]

[0046] Among them, HDPE is high-density polyethylene (density 0.942g / cm3, melting point: 124°C), the particle size of nickel powder is 3.50 μm, and the particle size of titanium carbide is 0.4 μm. The purity of magnesium hydroxide is 96.7 wt%.

[0047] The production process is as follows: weigh according to the material ratio shown in Table 1, put it into a vertical ball mill for pre-mixing for about 30 minutes, and divide it into 4 groups evenly after pre-mixing, and set the feed temperature of the internal mixer to 180°C, Add one group to the internal mixer, the speed is 25rpm, and the internal mixing time is 3 minutes; then the second group of materials is added, and the internal mixing time is 5 minutes; the third group of materials is added, and the internal mixing time is...

Embodiment 2

[0064] Others are the same as in Example 1, except that the formula is different. The formula (weight: gram) of the PTC material layer is: high density polyethylene 200, titanium carbide 720, nickel powder 800, magnesium hydroxide 30, processing aid 0.8.

Embodiment 3

[0066] Others are the same as in Example 1, except that the formula is different. The formula (weight: gram) of the PTC material layer is: high density polyethylene 200, titanium carbide 800, nickel powder 960, magnesium hydroxide 80, processing aid 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com