Electric controlled tester and testing method for preformance of high-pressure oil pump in use for coaxial tracks of engines

A high-pressure oil pump and test device technology, which is applied in the direction of engine testing, engine components, machines/engines, etc., can solve the problems of not directly reflecting the performance of high-pressure oil pumps, lack of versatility, and indirect methods, so as to facilitate the performance and structure of oil pumps Simplified, Performance Tested Immediate Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

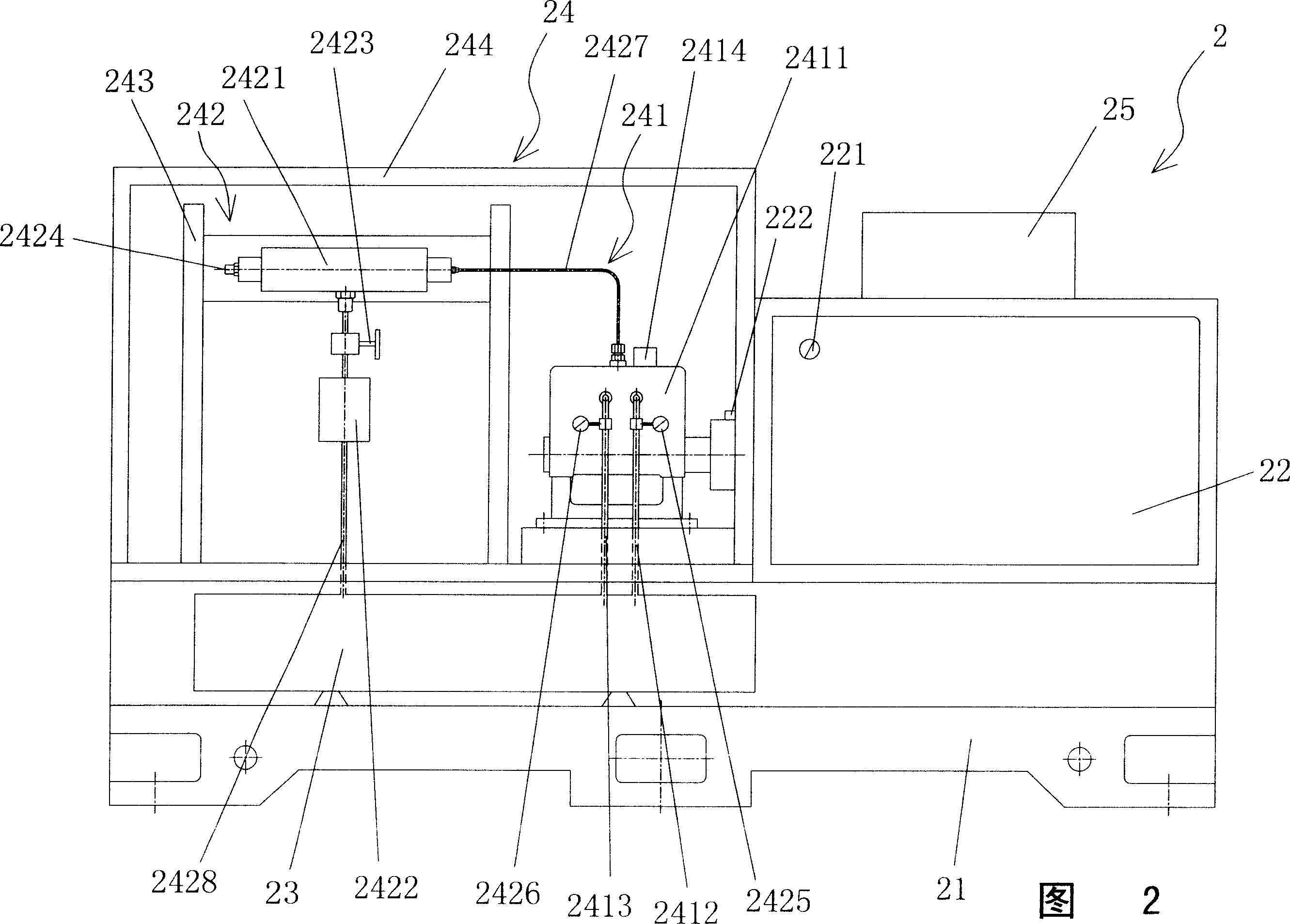

[0037] Please refer to Figure 2. The performance test device 2 of an electronically controlled high-pressure fuel pump for common rail of the present invention includes: a test bench chassis 21, a test bench drive system 22 arranged on the test bench chassis, a fuel supply system 23, a test system 24, and a measurement and control system 25. among them:

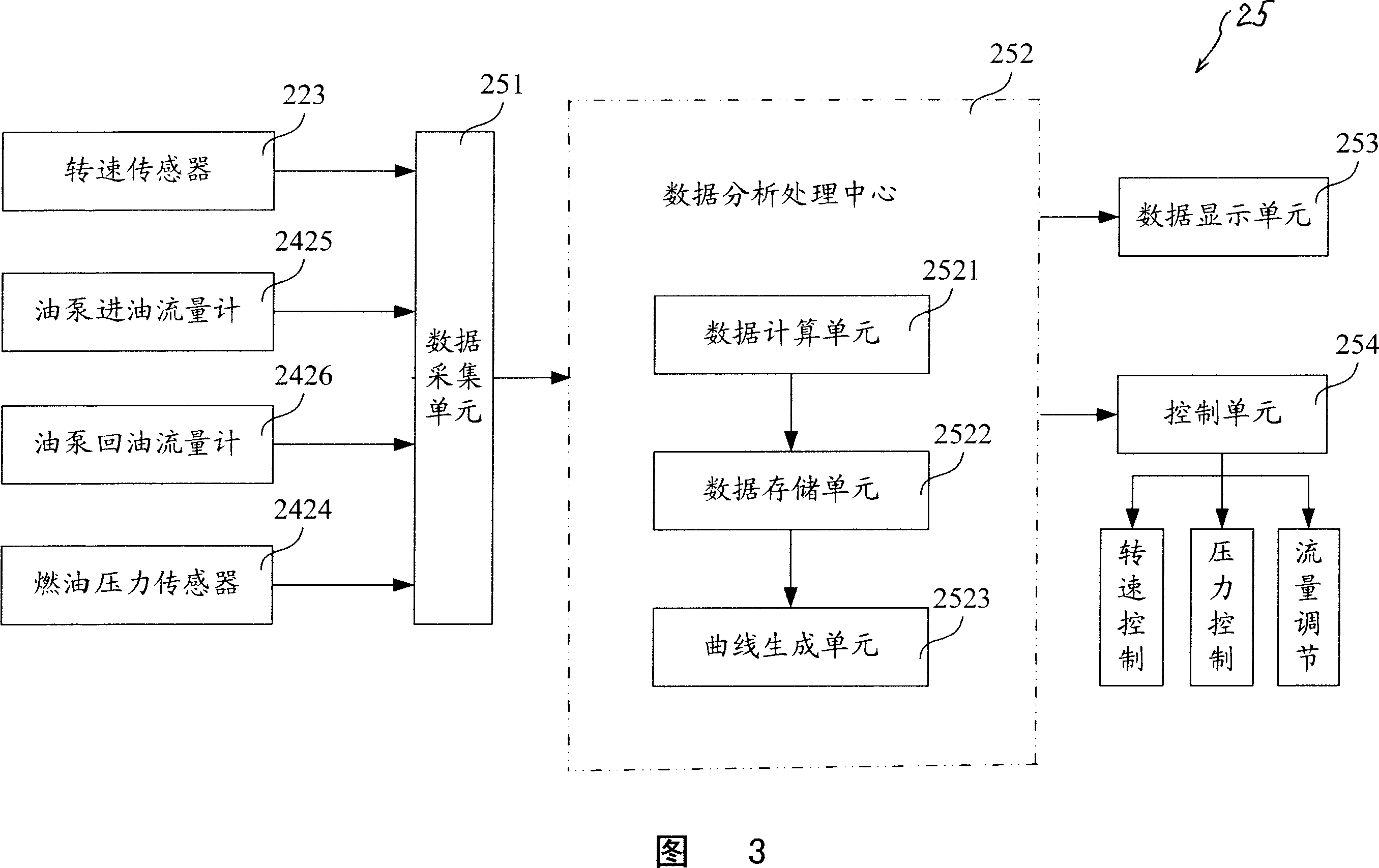

[0038] A driving motor (not shown), a rotation speed sensor 222 and a rotation speed adjusting device 221 are provided on the output shaft of the driving motor on the test bench driving system 22.

[0039] The test system 24 includes an oil pump component 241 and an oil quantity measuring component 242. The oil pump component 241 includes a high pressure oil pump 2411 driven by the test bench drive system 22, and an oil quantity adjustment solenoid valve is provided on the high pressure oil pump. 2414.

[0040] The fuel quantity measurement component 242 includes a fuel accumulator 2421, a pressure regulator chamber 2422, an adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com