Aerial pipe arrangement and method of aerially arranging pipes

A technology for overhead pipes and pipes, applied in the direction of pipe laying and maintenance, pipes/pipe joints/fittings, flange connections, etc., to avoid inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

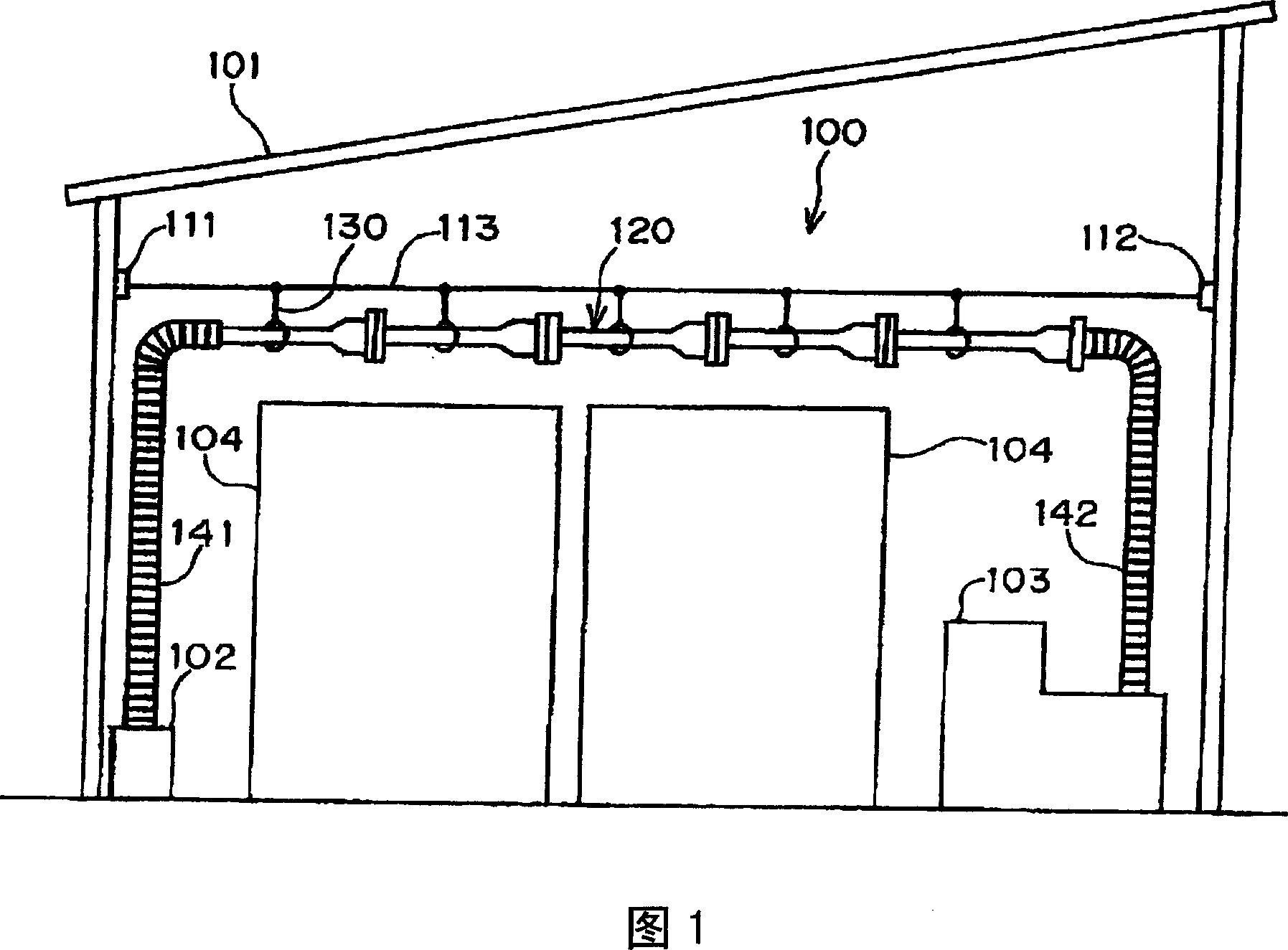

[0038] FIG. 1 illustrates an overhead duct structure 100 according to a first embodiment of the present invention.

[0039] An overhead duct structure 100 is erected in a factory 101 . An air compressor 102 is provided at one end of the factory 101 , and a machine 103 driven by compressed air is provided at the other end of the factory 101 . Assume that although the compressed air discharged from the air compressor 102 must be supplied to the machine 103, other machines 104 are provided between the air compressor 102 and the machine 103, and therefore, there is no place on the floor of the factory 101 for disposing the air compressor. 102 and machine 103 may be a space of conduits in fluid communication with each other.

[0040] The overhead pipe structure 100 according to the first embodiment of the present invention is preferably applied to a factory 101 .

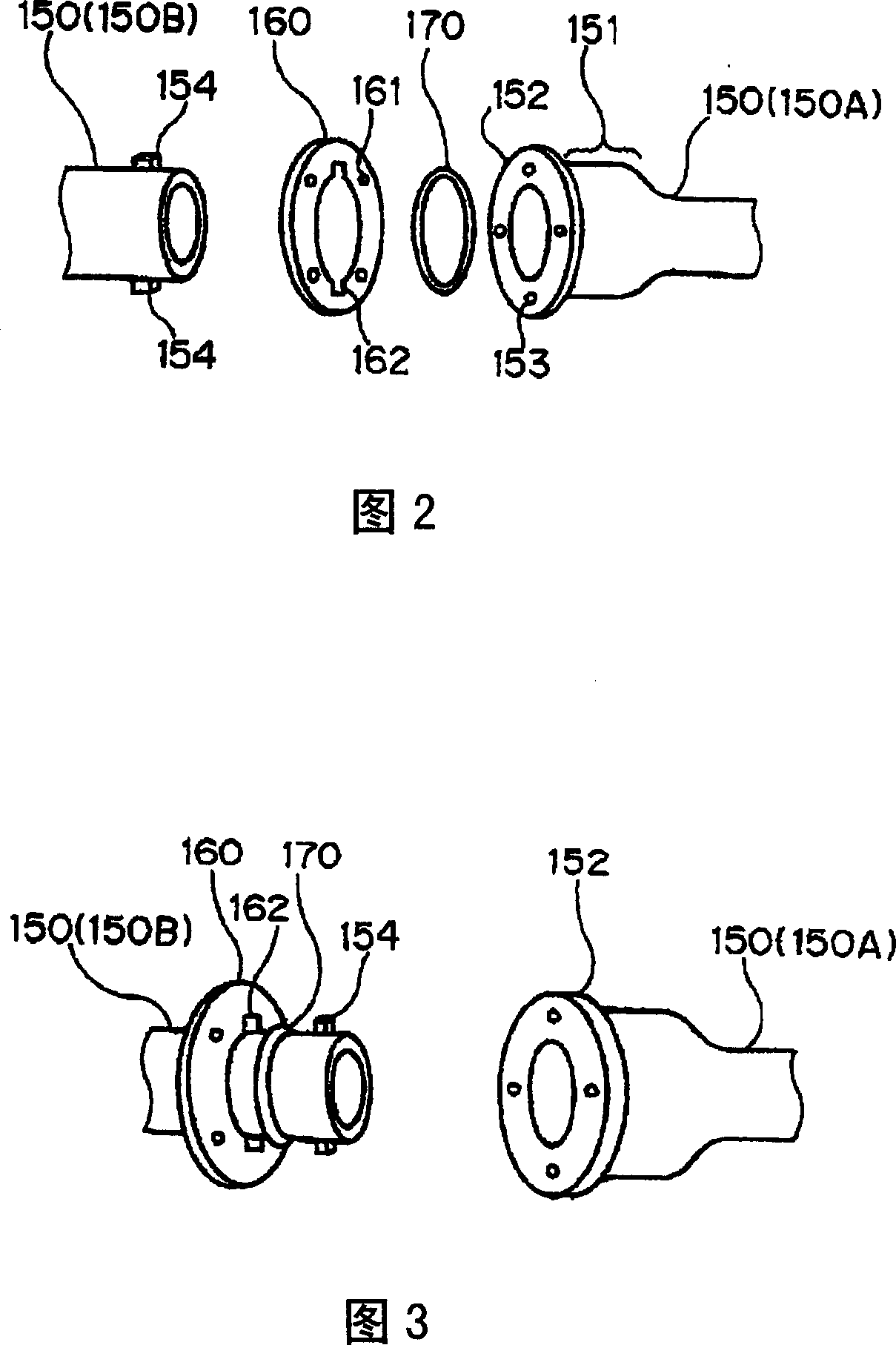

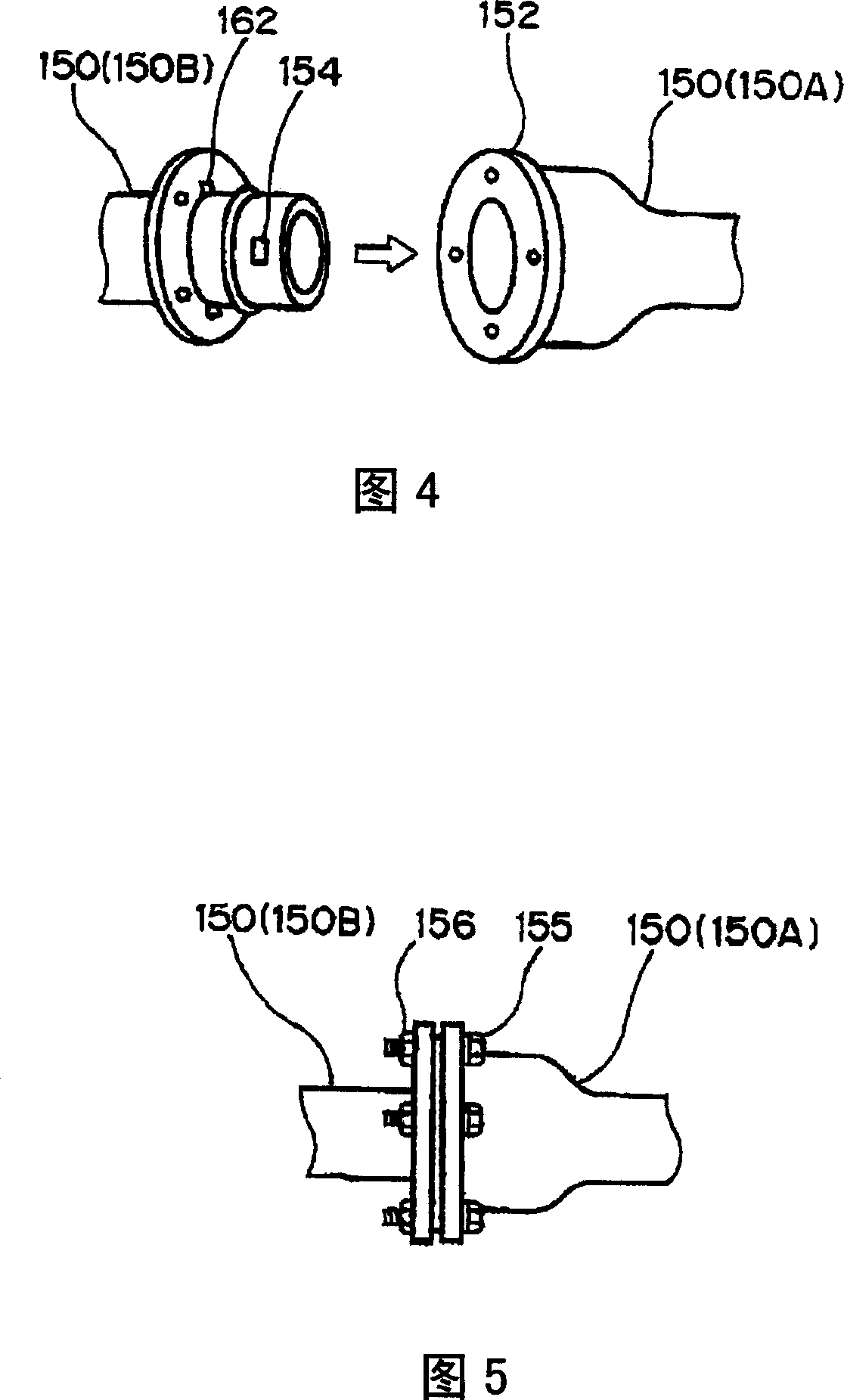

[0041] As shown in FIG. 1 , the overhead duct structure 100 according to the first embodiment includes a main cable ...

no. 2 example

[0090] FIG. 7 illustrates an overhead duct structure 200 according to a second embodiment of the present invention.

[0091] An overhead pipeline structure 200 according to a second embodiment of the present invention is erected between a first factory 201 and a second factory 202 .

[0092] The overhead duct structure 200 according to the second embodiment is structurally the same as the overhead duct structure 100 according to the first embodiment. Therefore, parts or elements corresponding to the first embodiment are provided with the same reference numerals and operate in the same manner as corresponding parts or elements in the first embodiment unless explicitly stated below.

[0093] Assume that the area 203 located between the first factory 201 and the second factory 202 is an area where it is impossible to install pipelines on the ground, such as a river, a railway, or a highway.

[0094] Even if there is an area 203 between the first factory 201 and the second factor...

no. 3 example

[0097] FIG. 8 illustrates an overhead duct structure 300 according to a third embodiment of the present invention.

[0098] As shown in FIG. 8, the overhead pipeline structure 300 according to the third embodiment of the present invention includes a first hollow supply rod 301 standing on the ground 350, a second hollow supply rod 302 standing on the ground 350, The main cable 303 tensioned between the apex of the supply rod 301 and the apex of the second supply rod 302, the fluid delivery tube 320 extending between the first and second supply rods 301 and 302, and the main cable 303 for the main cable 303 The hanger 330 from which the fluid delivery tube 320 is suspended.

[0099] In the overhead duct structure 300 according to the third embodiment, the main cable 303 is tensioned between the apex of the first supply rod 301 and the apex of the second supply rod 302 . That is, the apex of the first supply rod 301 corresponds to the first support 111 in the first embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com