Light diffuser plate of increasing light diffusion, and raising brightness

A light diffusion plate, light diffusion technology, applied in the field of diffusion plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the examiners have a further understanding and understanding of the structural features of the present invention and the effects achieved, I would like to add preferred embodiments and cooperate with detailed descriptions, and the descriptions are as follows:

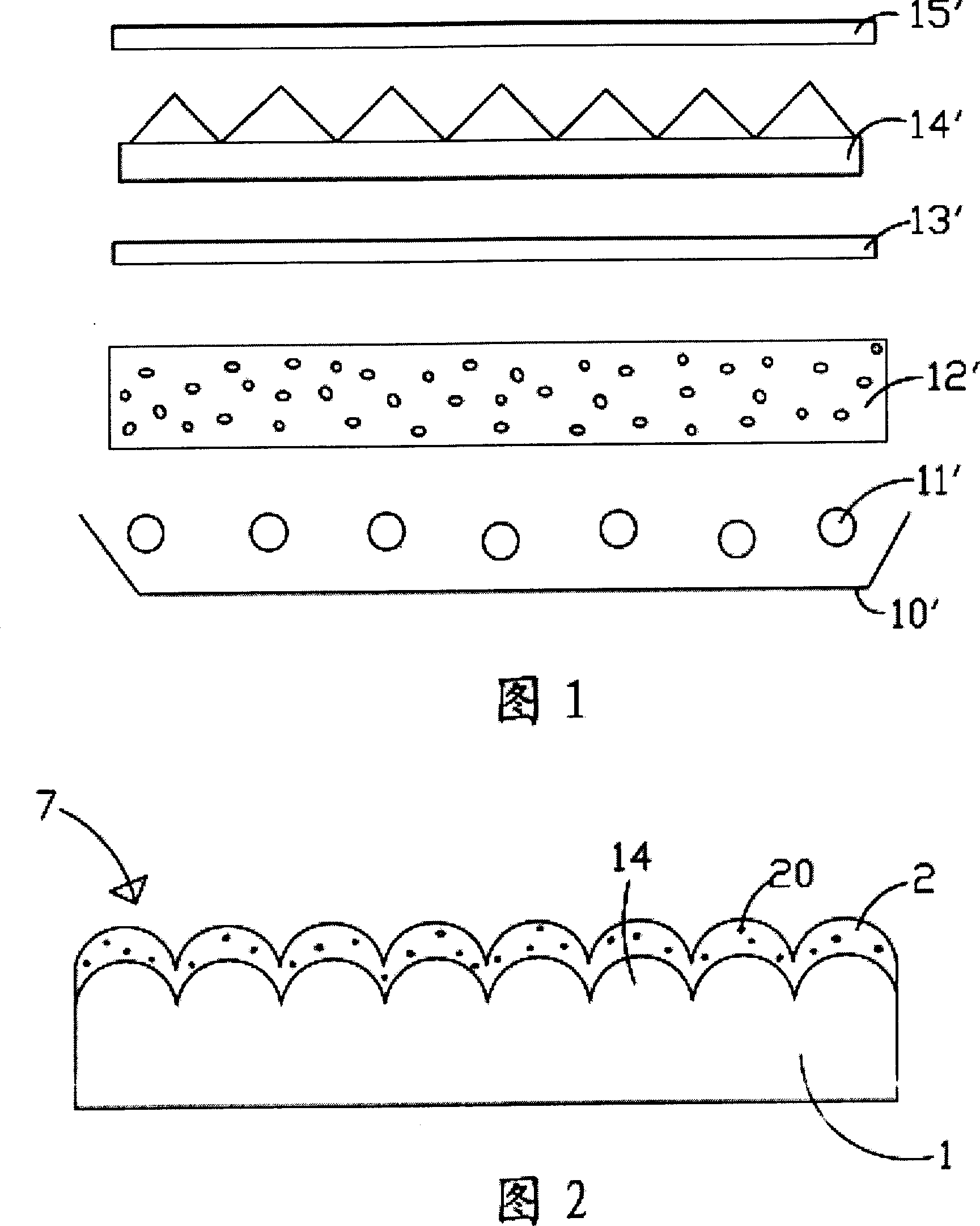

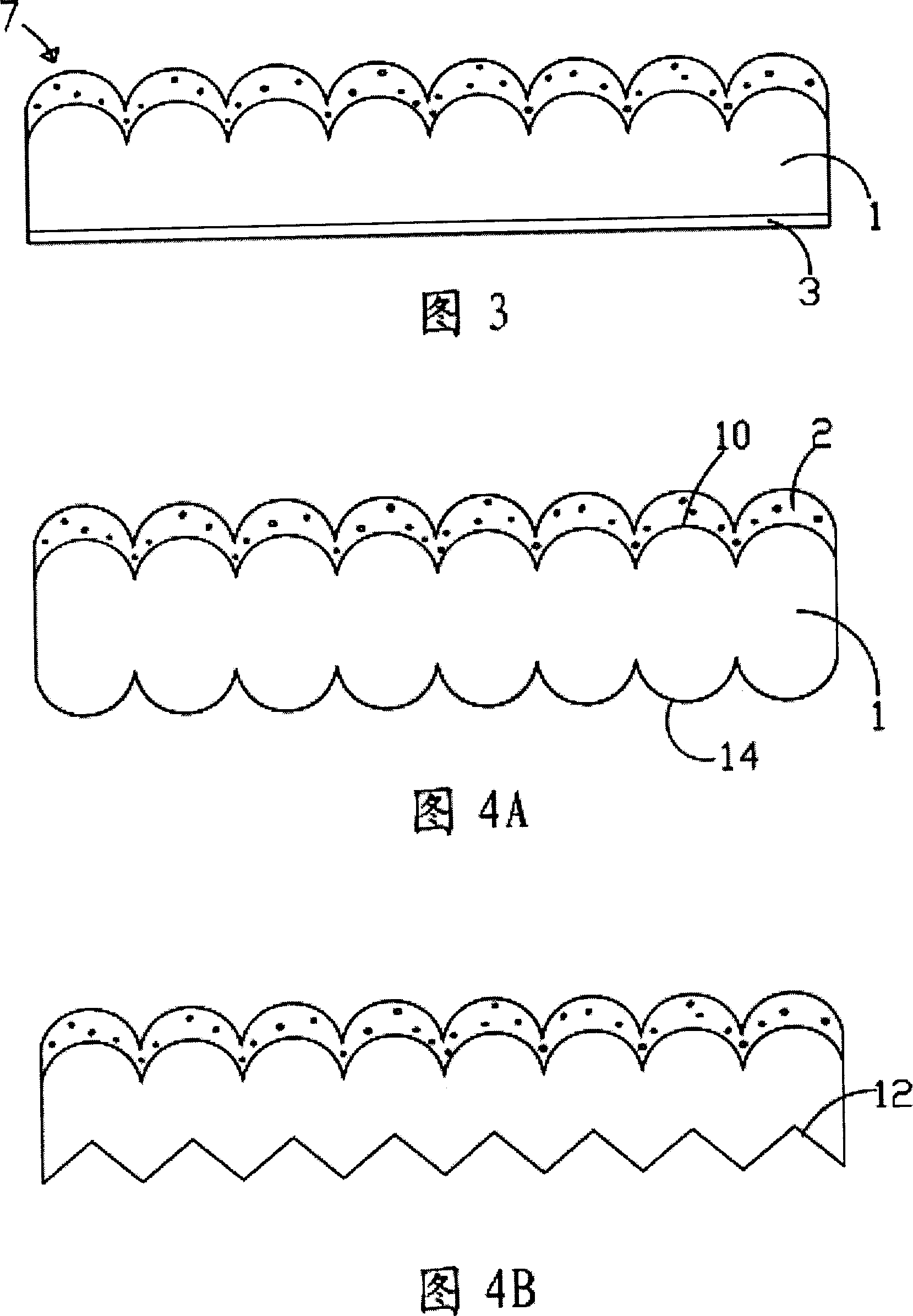

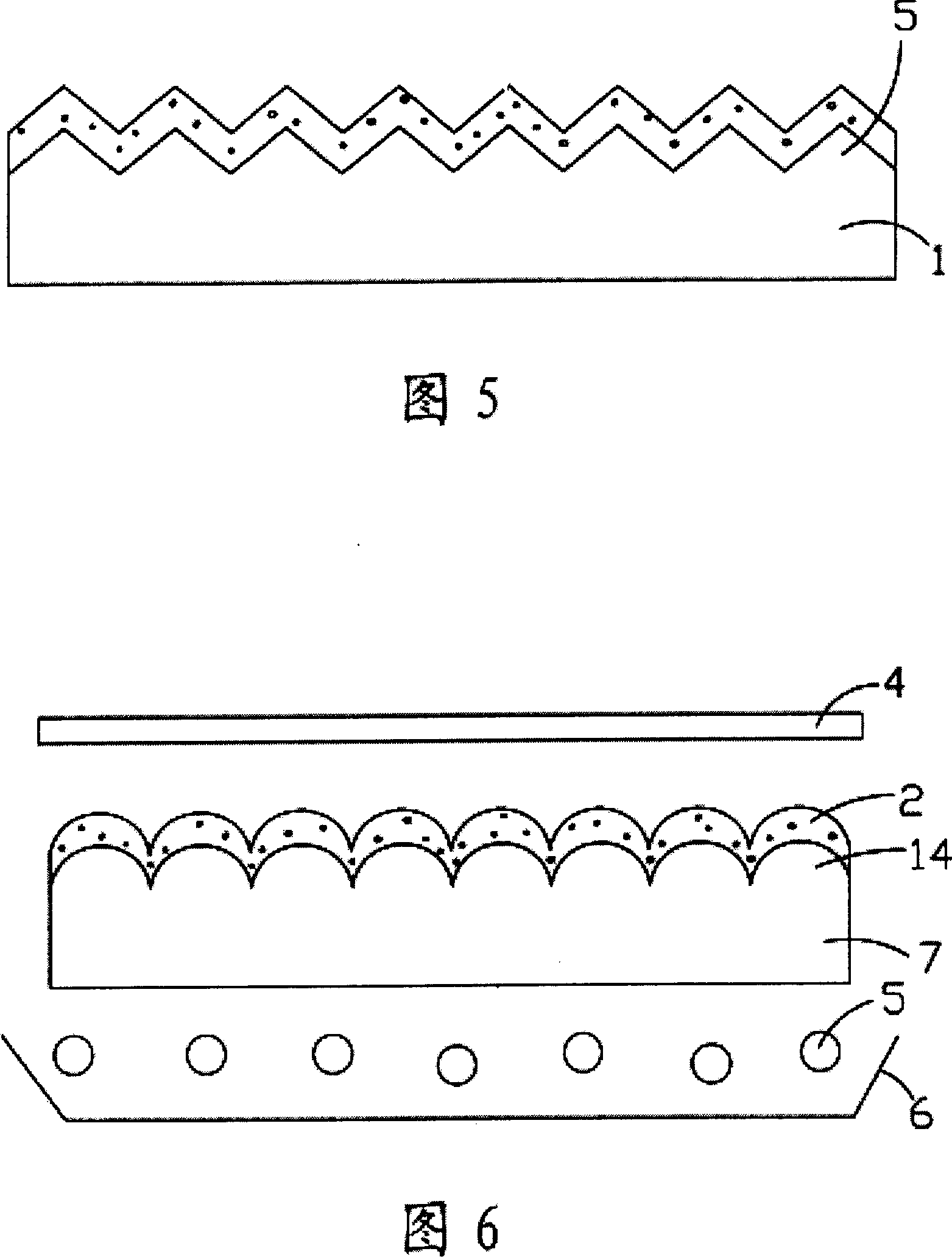

[0022] The conventional direct type backlight module includes a reflective sheet, a plurality of light sources, a light diffusion plate, a lower diffusion film, a prism sheet and an upper diffusion film, and then the optical sheets are combined together, which not only increases the time required for assembly. Therefore, the present invention provides a light diffusion plate that increases light diffusion and improves brightness, so as to reduce the structure of the direct type backlight module and reduce the manufacturing cost.

[0023] Please refer to FIG. 2 , which is a schematic structural diagram of a light diffusing plate according to a preferred embodiment of the present invention. Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com