Milling head with simple pendulum based on single axis

A single-axis turntable and milling head technology, applied in the direction of magnetic circuit rotating parts, large fixed members, electromechanical devices, etc., can solve the problems of inconvenient processing and complex structure, reduce the use of materials, reduce the difficulty of design and manufacture, The effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

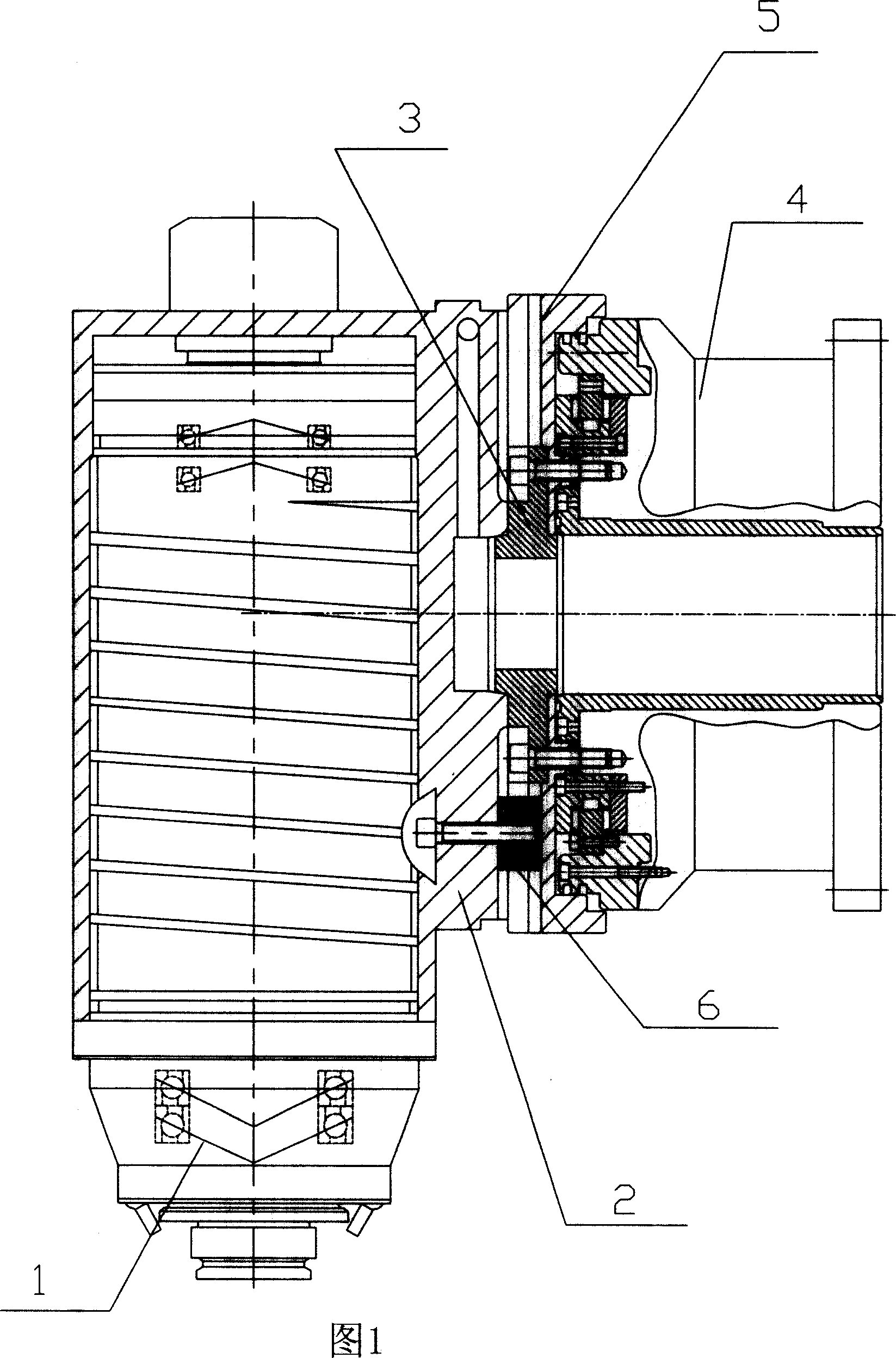

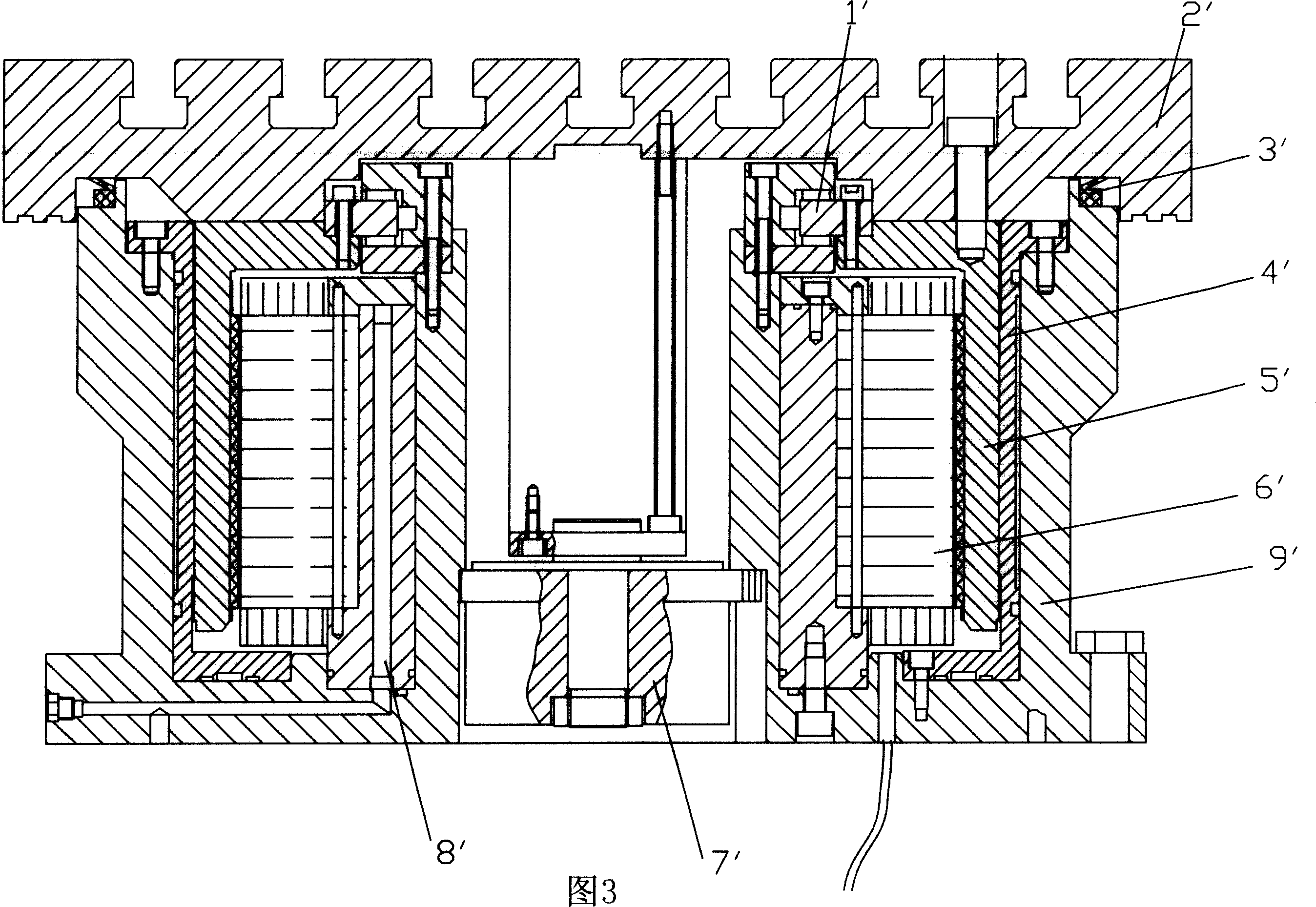

[0012] 1. Single-axis turntable driven by AC permanent magnet synchronous external rotor torque motor

[0013] In order to explain the present invention, a single-axis turntable driven by an AC permanent magnet synchronous external rotor torque motor will be described with reference to FIG. 3. The difference between the single-axis turntable in the figure and the turntable used in the present invention is that the turntable in FIG. 3 is arranged vertically. However, the turntable used in the present invention needs to be set horizontally, and the principle is completely the same. Through the description of the motor structure in Fig. 3, it is helpful to understand the single pendulum milling head of the present invention. In Fig. 3, the rotor 5'of the motor is directly connected to the turntable surface 2', which is usually fixed to the end of the rotor 5'by bolts. At the same time, the stator 6'located in the inner ring of the rotor 5'is connected to the housing 9'fixed to the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com