Device for modifying brick texture of ceramic wall and floor tiles

A technology for wall and floor tiles and brick bodies, which is applied to ceramic molding machines, supply devices, manufacturing tools, etc., can solve the problems of less change and rigidity, and achieve the effect of different and natural patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A brick body texture decoration method for ceramic wall and floor tiles, comprising the steps of:

[0017] (1) Sprinkling at least one decorative fabric in powder form on a reciprocating conveyor belt;

[0018] (2) Randomly throw at least one mixed and stirred block or sheet main fabric on the above-mentioned conveyor belt covered with decorative fabrics;

[0019] (3) Extrude the decorative fabric and the main fabric near the output end of the above-mentioned conveyor belt, and pile them up to the required basic shape;

[0020] (4) Sliding to the material board carried by another conveyor belt and whose surface area is slightly larger than the surface area of the floor tiles to be made;

[0021] (5) After being scraped and shaped, it is sent to the press for pressing and forming.

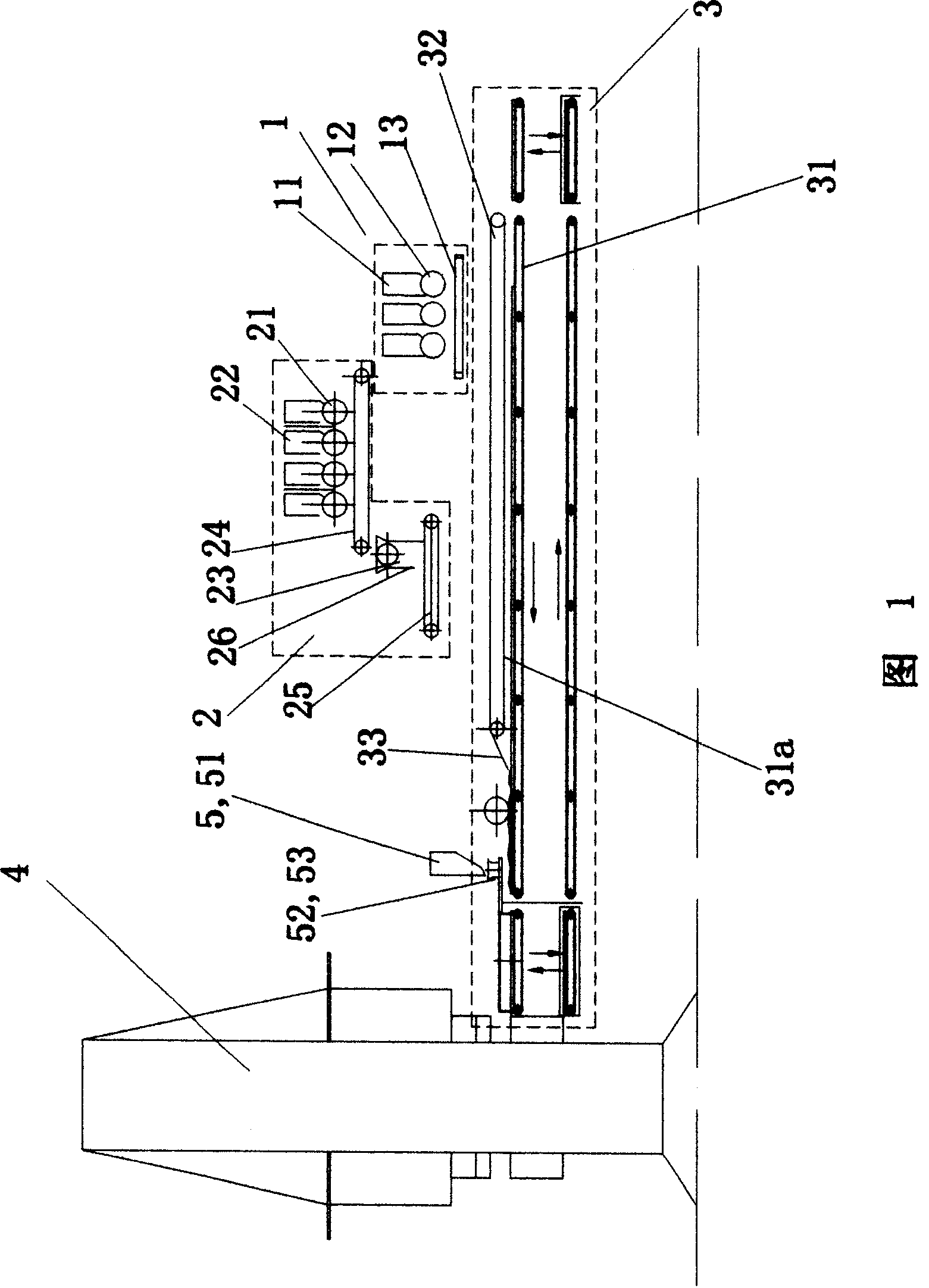

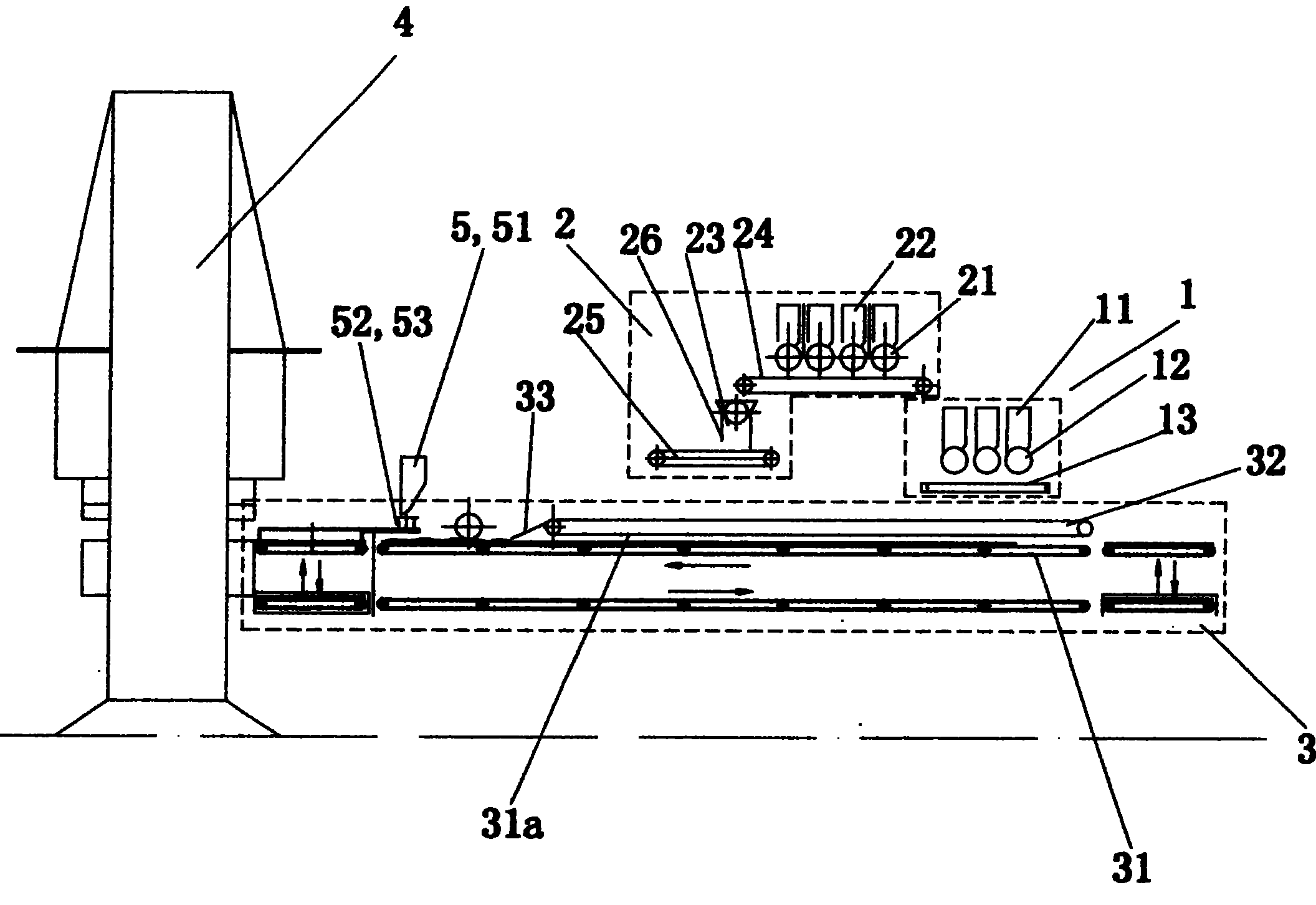

[0022] A device designed according to the above brick texture decoration method is shown in Figure 1, comprising a decorative fabric distributing device 1, a main fabric distributing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com