Rotary discharger

An unloader and rotor technology, applied in loading/unloading, rotary conveyors, conveyors, etc., to achieve the effect of extended service life, low power consumption, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

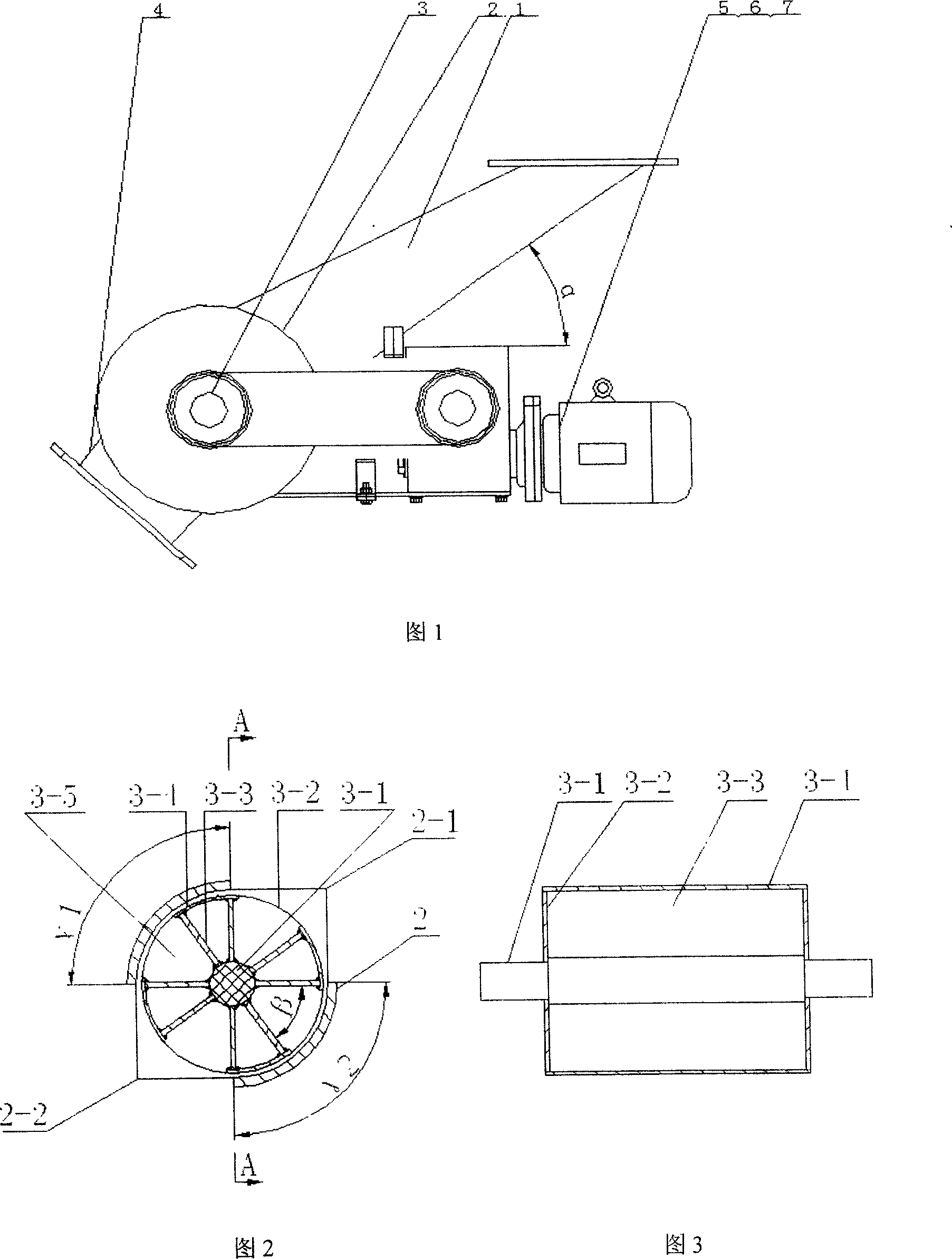

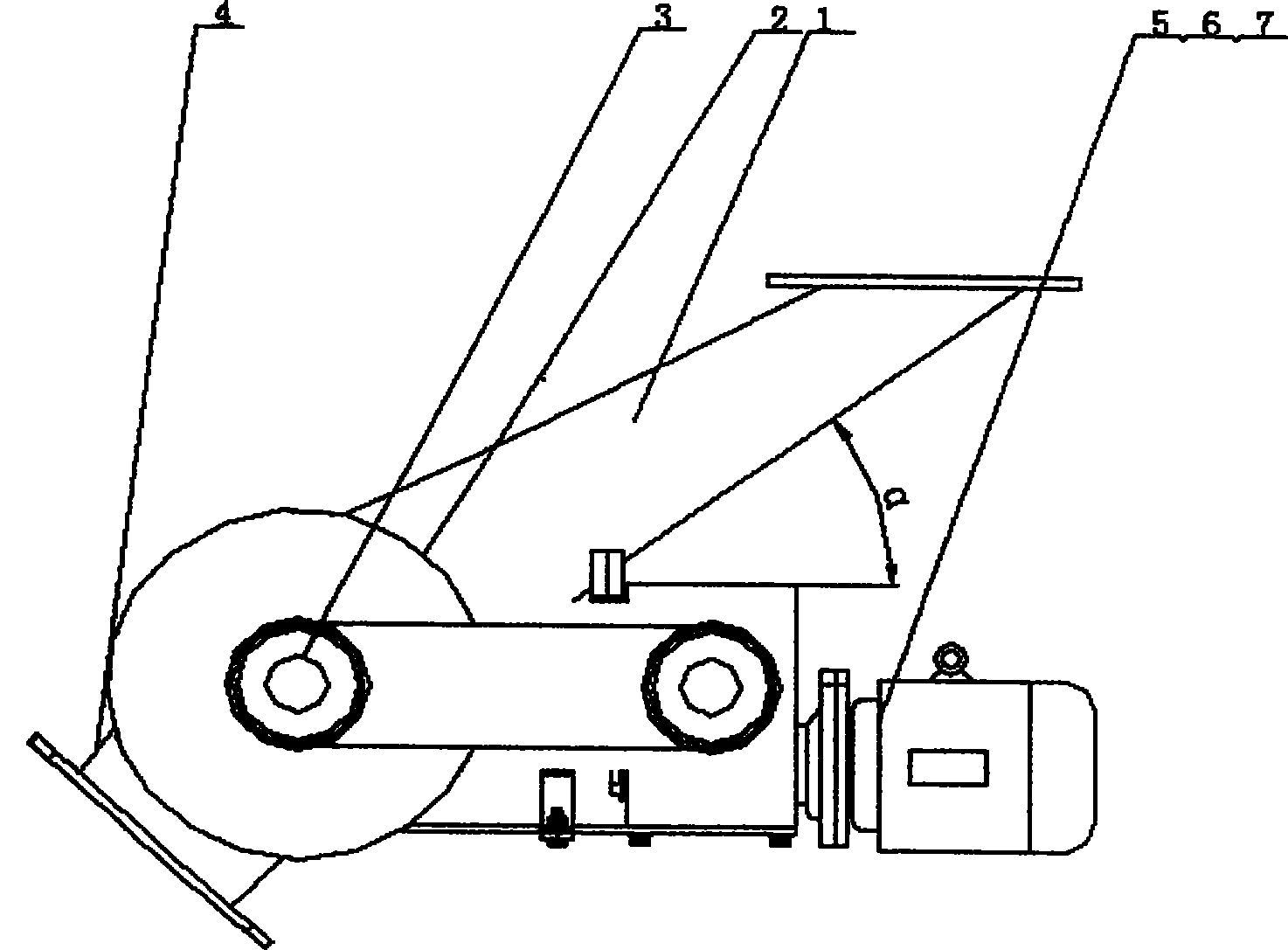

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] Examples of the present invention are figure 1 , The feed chute I is welded with carbon steel plate (Q235-A), and the chute angle is 45°. The unloader housing 2 and the unloader rotor 3 are made of wear-resistant 45# steel. The unloader rotor 3 has 8 blades altogether, and the included angle between the two blades is 45°. The unloader rotor has a total of 4 storage tanks, and the adjacent blades between the storage tanks are sealed with circular arc steel plates, a total of 4 places. The outer surface of the arc steel plate and the inner surface of the shell are precision machined, and the control gap is about 0.8mm. The angles of the two arcs of the housing are both 90°. The solid material in this embodiment is coke particles used for flue gas desulfurization, typical size: cylindrical coke particles with a diameter of 9mm and a length of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com