Technological process of curved-surface photovoltaic device and curved-surface photovoltaic device

A technological process and curved surface technology, which is applied to the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems such as the inability to bond glass to cells, and achieve the effect of simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

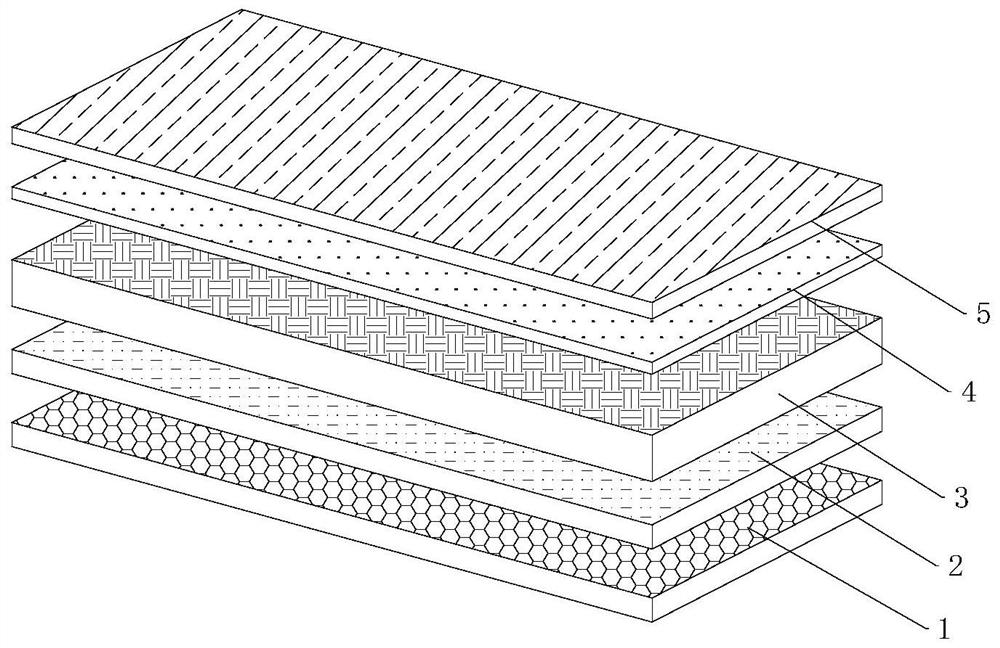

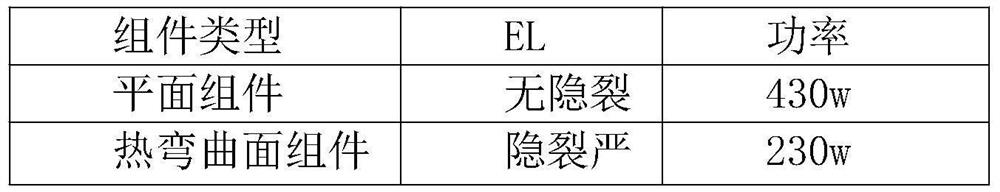

[0033] Such as figure 1 with figure 2 As shown, a process flow of curved surface photovoltaics includes the following steps:

[0034] Step 1: Lay encapsulation material on the surface of photovoltaic glass to form the first encapsulation layer, arrange the batteries on the encapsulation material, connect the batteries in series to form the battery layer, where the encapsulation material can be but not limited to EVA and POE one or more. Step 2: Lay the second encapsulation material on the battery layer to form the second encapsulation layer, and cover the surface of the second encapsulation layer with back glass; Edge sealing with edge banding tape to form a prefabricated sample; Step 4: Pre-laminate the prefabricated sample, put the double glass component into the laminator for lamination during pre-lamination, and set the temperature during lamination to 120 -140 degrees Celsius, and the degree of cross-linking of the prefabricated samples after lamination: 15%-30%. In ...

Embodiment 2 1 ( or ) Embodiment approach

[0036] Embodiment 2 is another optional (or preferred) implementation of the present invention, comprising the following steps:

[0037] Step 1: Lay encapsulation material on the surface of photovoltaic glass to form the first encapsulation layer, arrange the batteries on the encapsulation material, connect the batteries in series to form the battery layer, where the encapsulation material can be but not limited to EVA and POE one or more. Step 2: Lay the second encapsulation material on the battery layer to form the second encapsulation layer, and cover the surface of the second encapsulation layer with back glass; Edge sealing with edge banding tape to form a prefabricated sample; Step 4: Pre-laminate the prefabricated sample, put the double glass component into the laminator for lamination during pre-lamination, and set the temperature during lamination to 130 degrees Celsius, and the degree of crosslinking of the prefabricated samples after lamination is: 15%-30%. In thi...

Embodiment 3

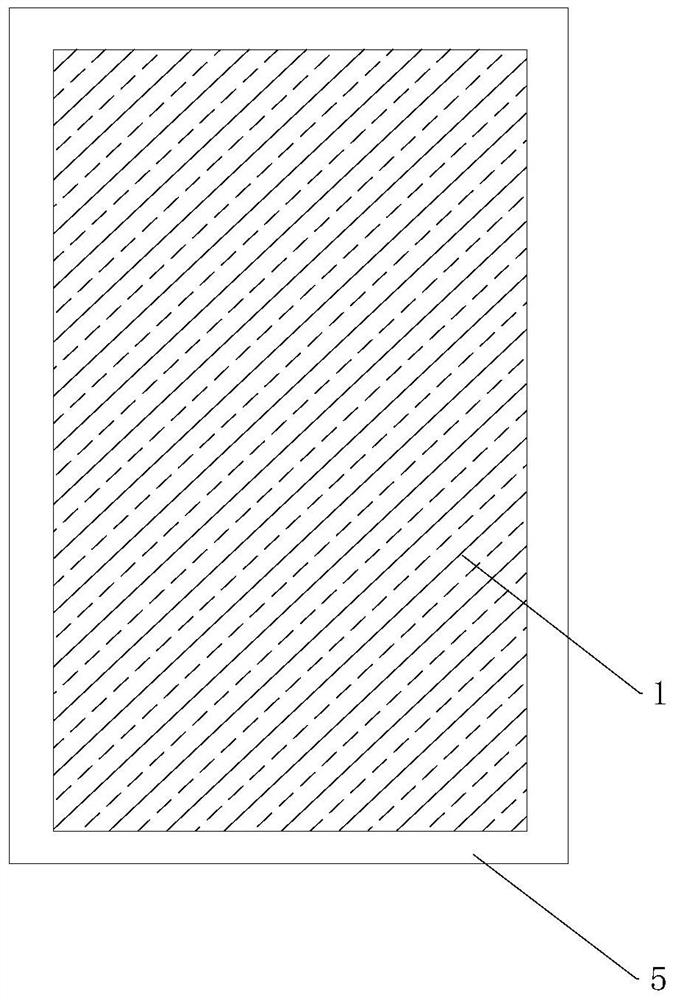

[0044] figure 2 It is a kind of curved photovoltaic provided by the present invention, which includes photovoltaic glass, a first encapsulation layer, a battery layer, a second encapsulation layer, and a backplane glass that are laminated sequentially from bottom to top. The sides of the photovoltaic glass, the first encapsulation layer, the battery layer, the second encapsulation layer and the back glass are provided with sealing edges.

[0045] In summary,

[0046] Each device selected in this application is a general standard or a component known to those skilled in the art, and its structure and principle can be known to those skilled in the art through technical manuals or through conventional experimental methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com