Tempered stone curtain wall board with prestress

A technology of prestressed and curtain wall panels, which is applied in the field of building decoration materials, can solve problems such as easy loosening of composite materials and pre-embedded materials, inability to make the surface of material panels larger, and shortened service life, so as to reduce labor intensity requirements, avoid dust and Noise pollution, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

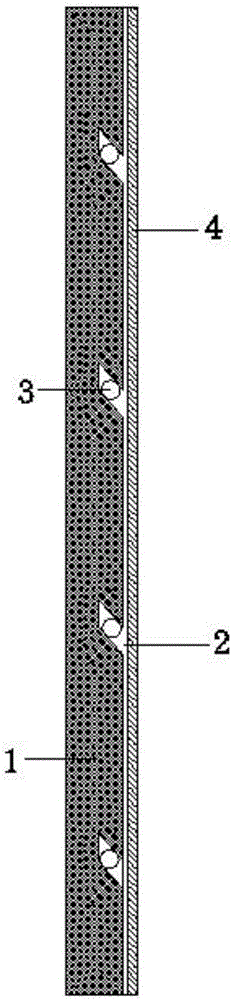

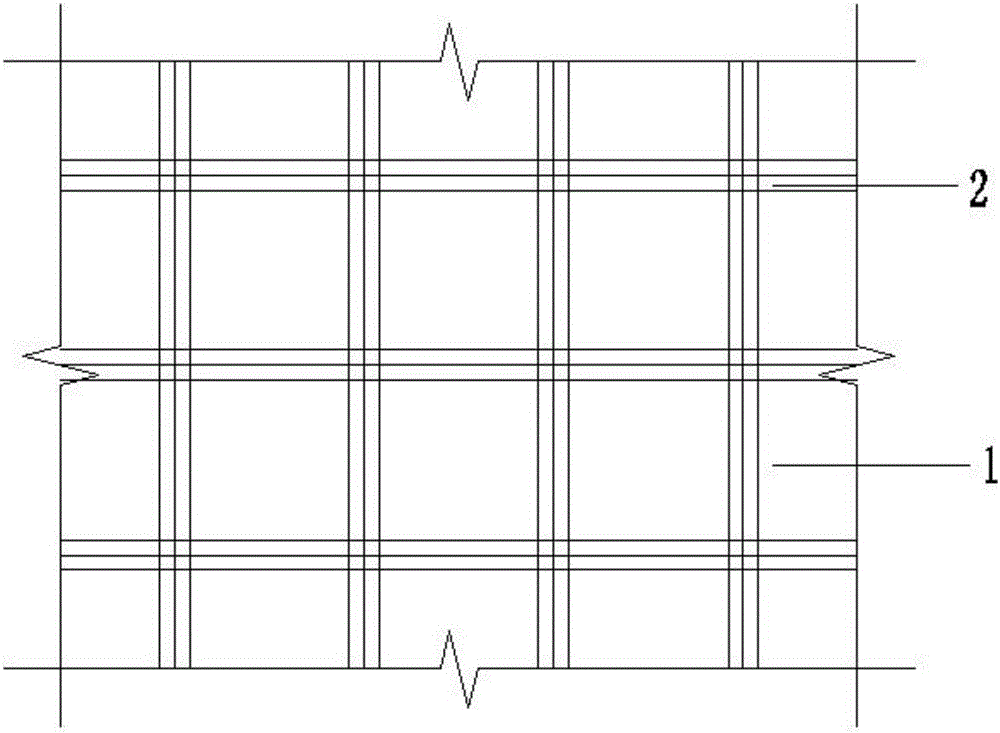

[0043] Such as Figure 1~4 As shown, a prestressed tempered stone curtain wall panel includes a stone panel 1, a steel mesh structure 3 and an organic plastic panel 4. The thickness of the stone panel 1 is 1.5 cm, and grooves are made in a well-shaped shape on its back side. The steel The grid structure 3 corresponds to the well-shaped notch 2, and is pre-embedded in the notch 2 with epoxy resin glue to form the "toughened" structural plate of the curtain wall; the organic plastic plate 4 is arranged on the back of the stone plate 1, and the two pass through Structural adhesive bonding to enhance the "tempered" function.

[0044] The depth direction of the notch 2 is inclined relative to the back of the stone plate 1, and the inclination angle α is 45 degrees. When the stone slab 1 was subjected to wind pressure, the inclined notch 2 ( Figure 4 Middle A) forms a partial barrier to the internal steel mesh structure 3, generates resistance, effectively prevents the stone plat...

Embodiment 2

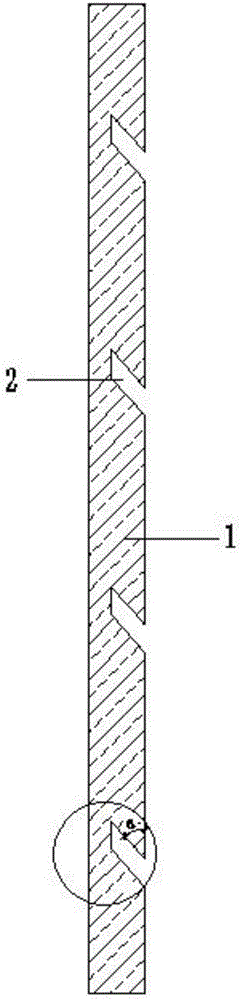

[0053] Such as Figure 5 As shown, the depth direction of two adjacent notches 2 is inclined to the opposite side of the back of the stone plate 1; steel bars are put into the notches 2 correspondingly before production, and the intersections of horizontal and vertical steel bars are welded to form a steel mesh structure 3. Lock and fix the steel mesh structure 3; it can be installed directly without distinguishing the direction of the notch 2 during dry hanging, eliminating the need to confirm the direction of the notch 2 before dry hanging, improving the efficiency of dry hanging and ensuring the normal service life of the curtain wall panels.

[0054] Other parts are identical with embodiment 1.

Embodiment 3

[0056] Such as Figure 6As shown, the depth direction of the notch 2 is perpendicular to the back of the stone plate 1; it can be installed directly without distinguishing the direction of the notch 2 during dry hanging, and the confirmation of the direction of the notch 2 before dry hanging is omitted to ensure the normal use of the curtain wall panel life.

[0057] Other parts are identical with embodiment 1.

[0058] There are many ways to dry hang the curtain wall panel of the present invention:

[0059] 1. If Figure 7-10 As shown, there is a pre-embedded screw 5 perpendicular to the plane of the steel mesh structure 3 butt welded at the junction of the steel mesh structure 3 horizontal and vertical steel bars, and the screw 5 is used for the connection between the stone plate 1 and the fixed base; 5. A cross groove 51 is formed at the end of the cap. The structural features such as the width and depth of the groove 5 coincide with the position of the connection point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com