Floating square matrix and floating type photovoltaic system

A photovoltaic system and floating technology, applied in the field of photovoltaic power generation, can solve the problems of insufficient buoyancy of the square array structure, insufficient square array rigidity, deformation of connecting rods, etc., and achieve the effects of uniform force, reduced deposition, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

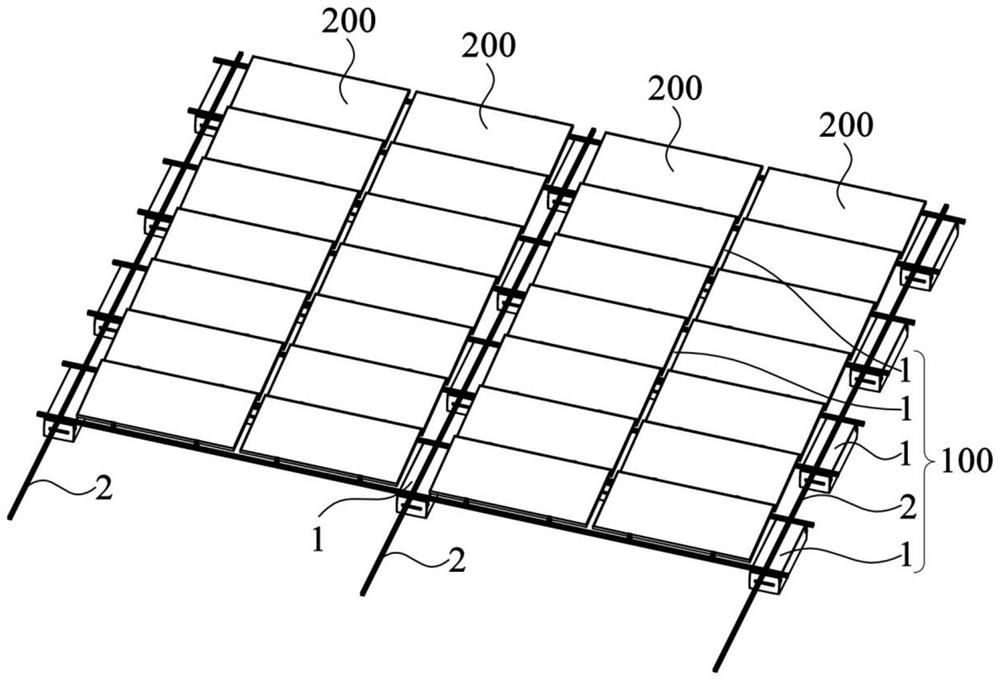

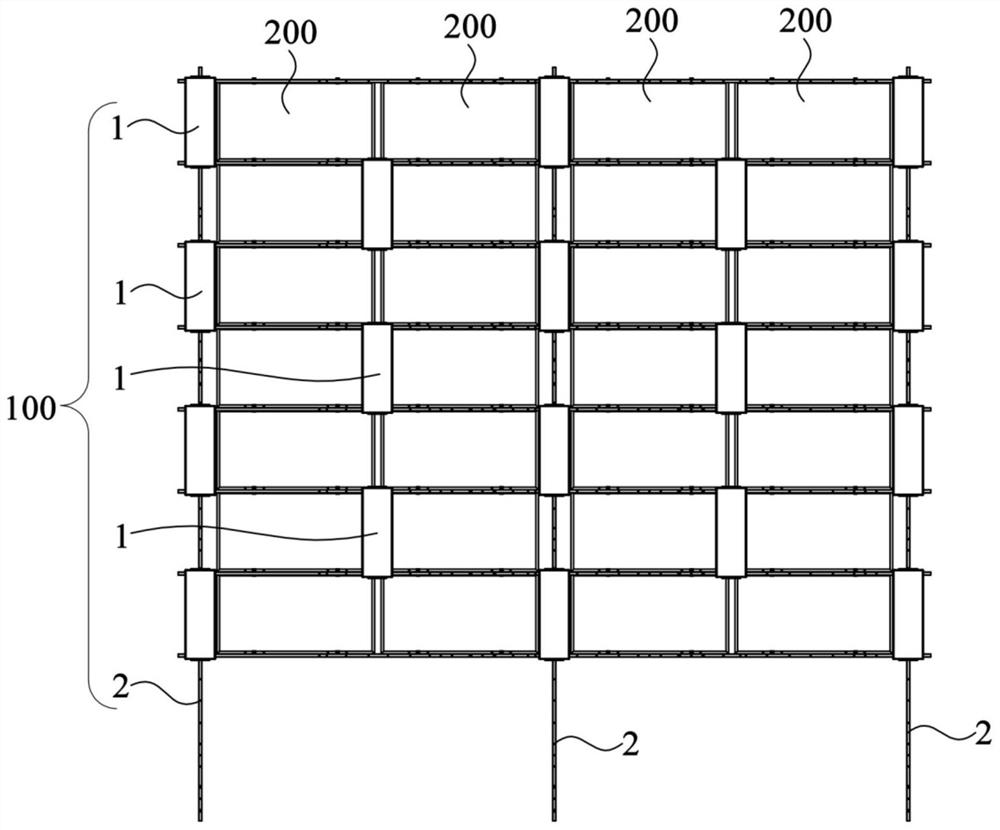

[0044] Such as figure 1 and figure 2 As shown, this embodiment provides a floating photovoltaic system, which is suitable for various scenarios such as drinking water reservoirs, hydropower station reservoirs, offshore waters, and extremely cold regions. The floating photovoltaic system includes a floating square array 100 and a photovoltaic power station, wherein , the floating square array 100 can be placed on the water surface and support a photovoltaic power station located on the water surface. The photovoltaic power station includes a plurality of photovoltaic modules 200 and a plurality of electrical equipment (not shown in the figure), and the photovoltaic module 200 is used to convert sunlight into For electric energy, the photovoltaic module 200 is electrically connected to the electrical equipment, and the electrical equipment is used for converging the current generated by the photovoltaic module 200 . It should be noted that, in this embodiment, the electrical e...

Embodiment 2

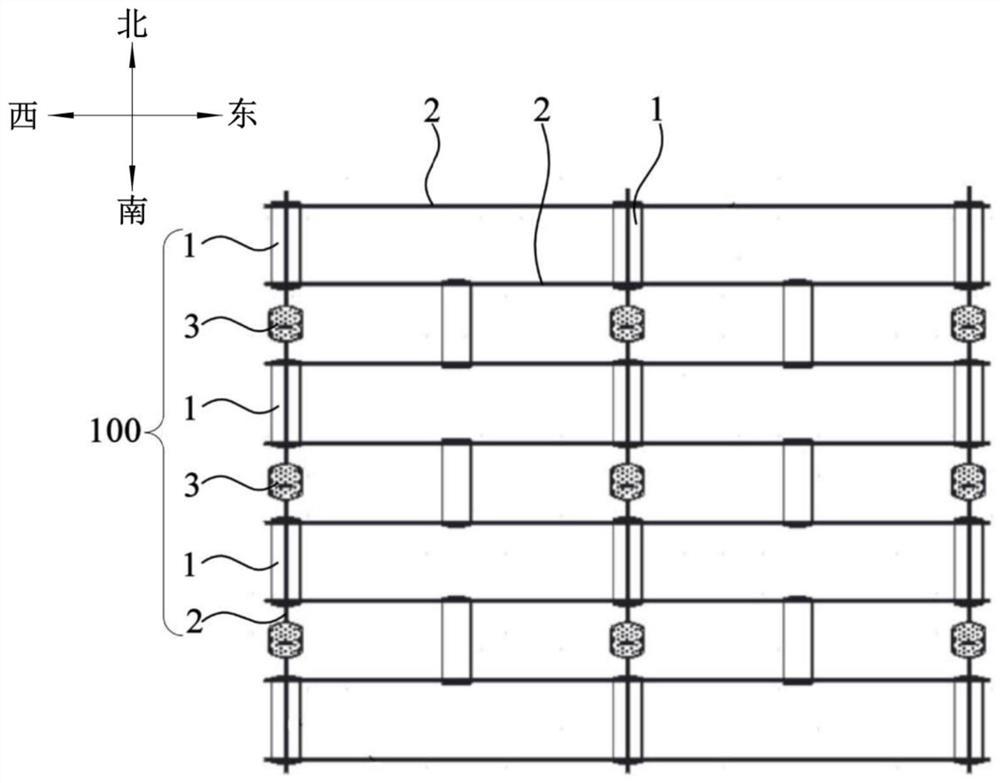

[0059] The floating square array 100 provided in this embodiment is basically the same as that in the first embodiment. The difference between the floating square array 100 provided in this embodiment and the first embodiment is that the operation and maintenance cover plate 3 is fixed in a different way.

[0060] Such as Figure 7 ~ Figure 9 As shown, both ends of the operation and maintenance cover plate 3 provided in this embodiment are respectively connected to two adjacent connecting rods 2 extending along the width direction of the main floating body 1 . This setting method can not only ensure that both ends of the operation and maintenance cover 3 in the width direction can be connected with the connecting rod 2, but also ensure the stability of the operation and maintenance cover 3. 3, the structure is simpler, and the installation cost is also reduced. It should be noted that when both ends of the operation and maintenance cover plate 3 in the width direction are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com