High efficiency low-temperature-rise induction cooker

A technology of induction cooker and low temperature, applied in the field of induction cooker, can solve the problems of IGBT temperature rise, large turn-on loss, etc., and achieve the effects of reducing operating frequency, large duty ratio and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings:

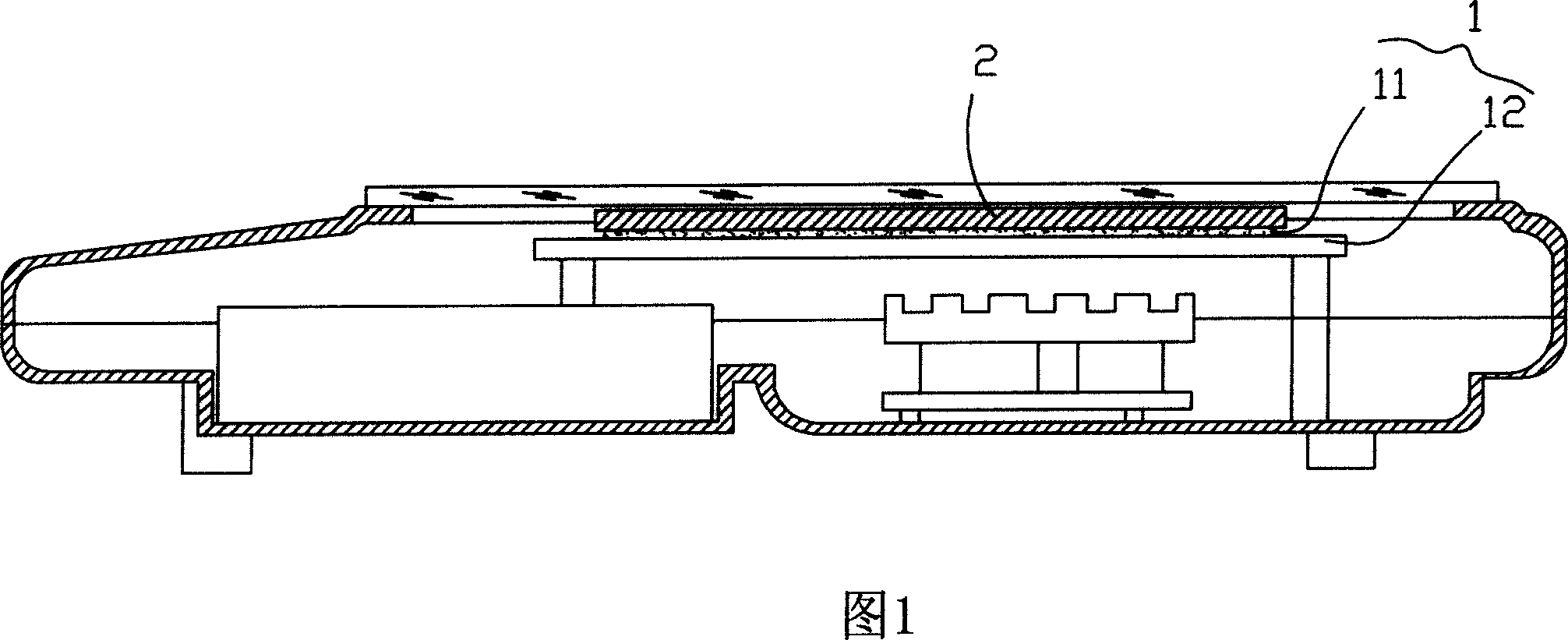

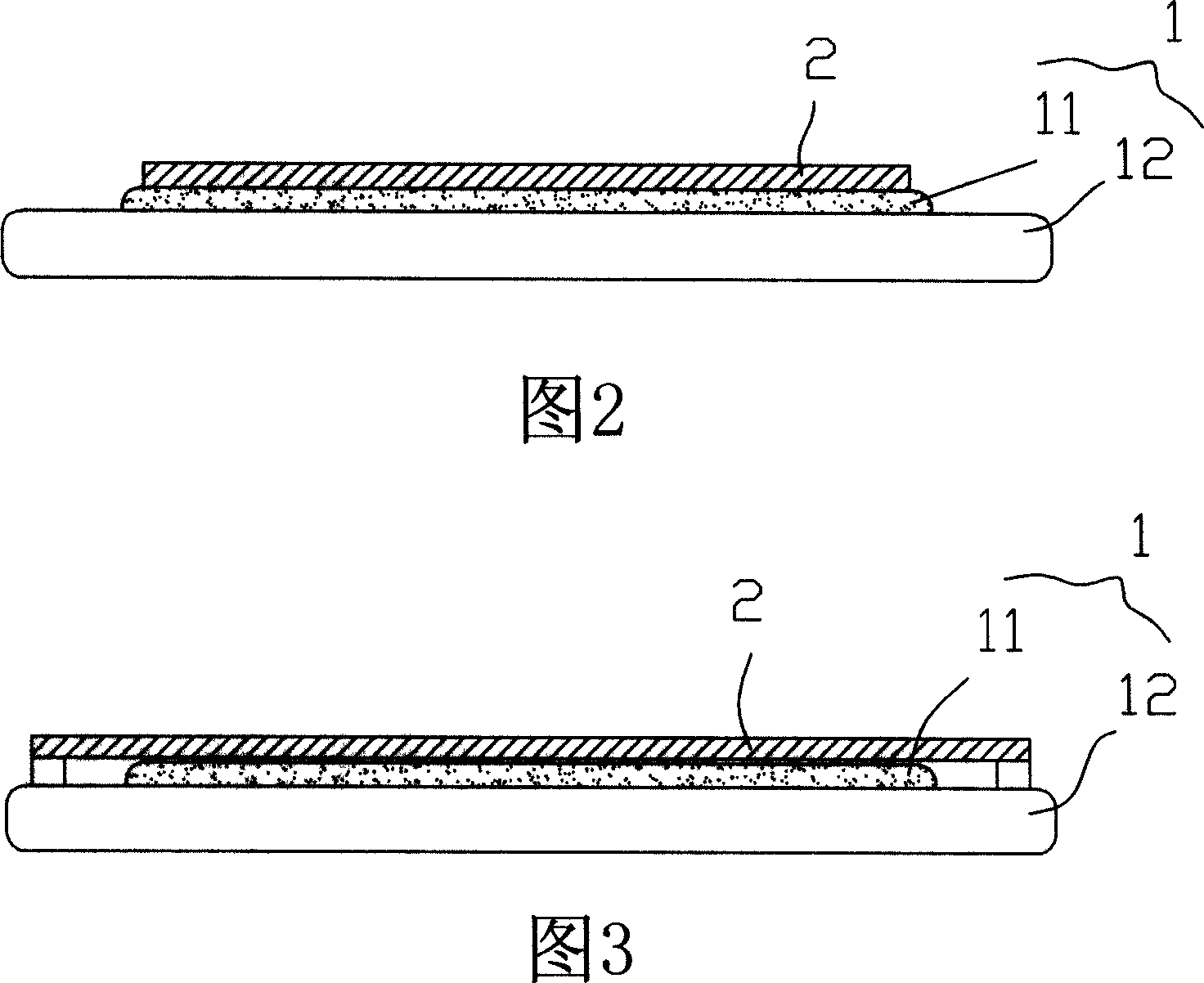

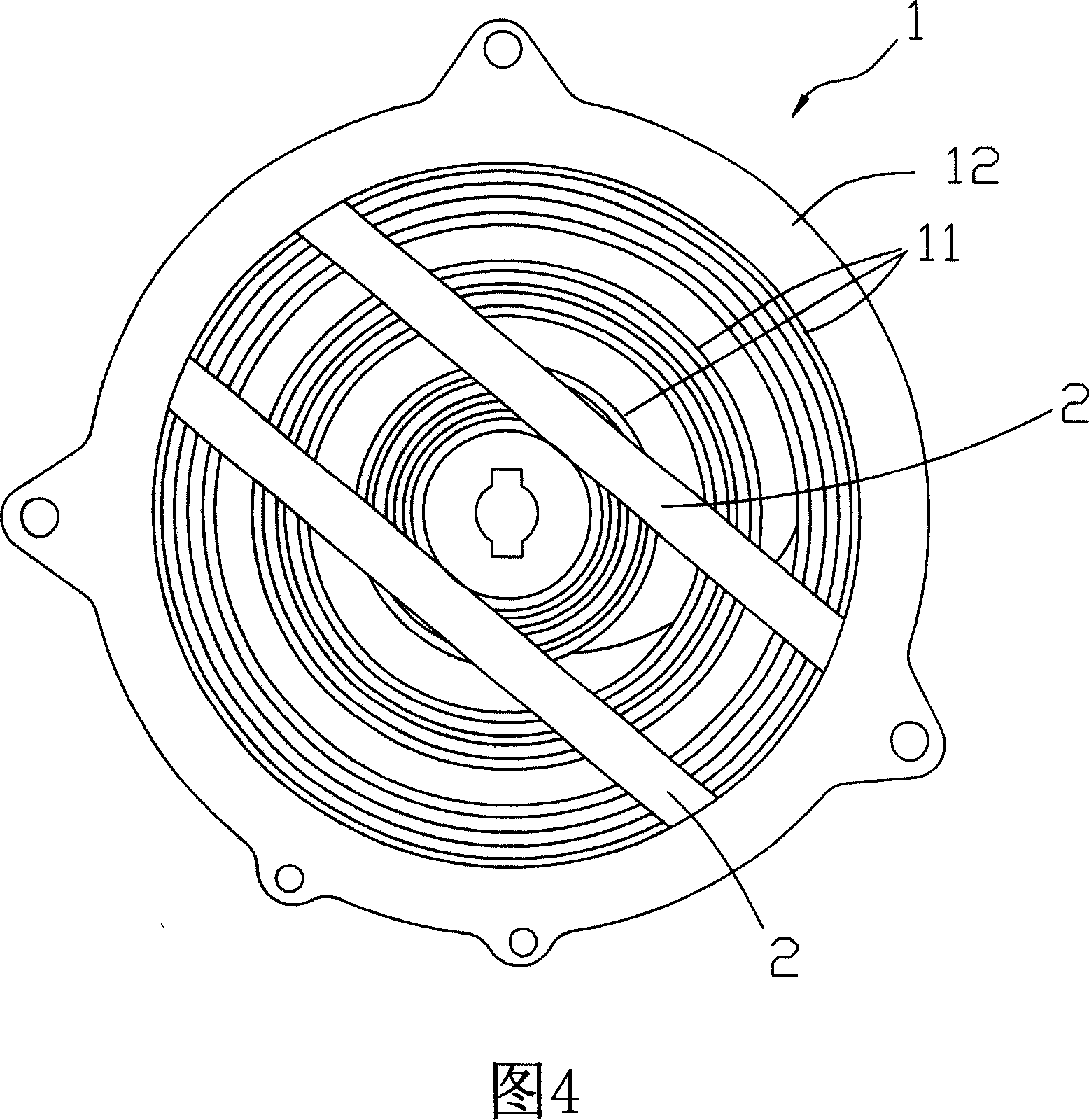

[0014] 1 to 4, the induction cooker of the present invention includes all the accessories of the induction cooker, such as furnace body, heating coil 1, circuit board and IGBT, etc. The heating coil 1 is installed in the furnace body, and the heating coil 1 One or more magnetic strips 2 are attached to the upper side, that is, the upper side of the heating coil 11, and the winding structure of the heating coil 11 can be continuous tight winding or ring-divided winding.

[0015] When in use, the magnetic stripe 2 attached to the heating coil 11 can increase the inductance and Q value of the heating coil 1. The additional magnetic stripe 2 and the heating coil 11 and the induction cooker on the back of the heating coil 11 The magnetic blocks with radial design work together to strengthen the magnetic field, improve the high-frequency operating characteristics of the inductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com